Cracking apparatus for producing myrcene by cracking Beta-pinene

A cracking device and myrcene technology, applied in chemical/physical/physical chemical nozzle reactors, organic chemistry, chemical instruments and methods, etc., can solve problems such as increased cracking time, reduced product yield, and unstable myrcene , to achieve the effect of uniform heating of the gas, reducing the generation of by-products, and improving the yield and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

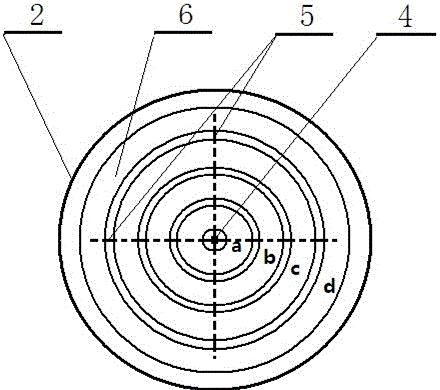

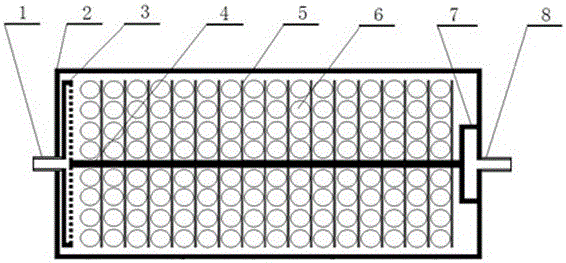

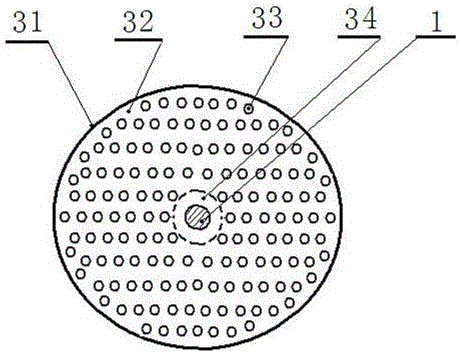

[0023] as attached figure 1 Shown, the cracking device of described β-pinene cracking and producing myrcene comprises cracking device housing 2, cracking pipe 6, inlet pipe 1, air outlet pipe 8 and jet device 3, in one end of described cracking device housing 2 Gas injection device 3 is set, and described inlet pipe 1 is connected with gas injection device 3, and the gas injection hole 33 of gas injection device 3 shoots to the other end in cracking device housing 2, and the other end of cracking device shell 2 is provided with air outlet pipe 8; The other end of the cracking device housing 2 is provided with a shaft support 7, and the cracking tube 6 is arranged in the cracking device housing 2, and is fixed on the fixed shaft 4 by the tube bracket 5, and the cracking tube 6 is provided with 16 groups, Each group is 8 cracking tubes of mutual concentric circle structure; the surface of cracking tube 6 is provided with catalyst layer;

[0024] Said air injection device 5 comp...

Embodiment 2

[0027] Cracking tube 6 is provided with 10 groups in this device, and each group is 10 cracking tubes of mutual concentric circle structure, and all the other features are identical with embodiment 1. After being cracked by this device, the yield of myrcene is ≥96.25%, and the purity is ≥97.09%.

Embodiment 3

[0029] Cracking tube 6 is provided with 20 groups in this device, and each group is 4 cracking tubes of mutual concentric circle structure, and all the other features are identical with embodiment 1. After being cracked by this device, the yield of myrcene is ≥92.13%, and the purity is ≥96.57%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com