Surface protective film and optical component attached with the same

A technology of surface protection film and peeling film, which is applied in the direction of optical components, optics, film/sheet adhesive, etc., can solve the problems of difficult to paste FPR film, high peeling static voltage, etc., achieve small pollution, improve productivity, Effect of reducing static peeling voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

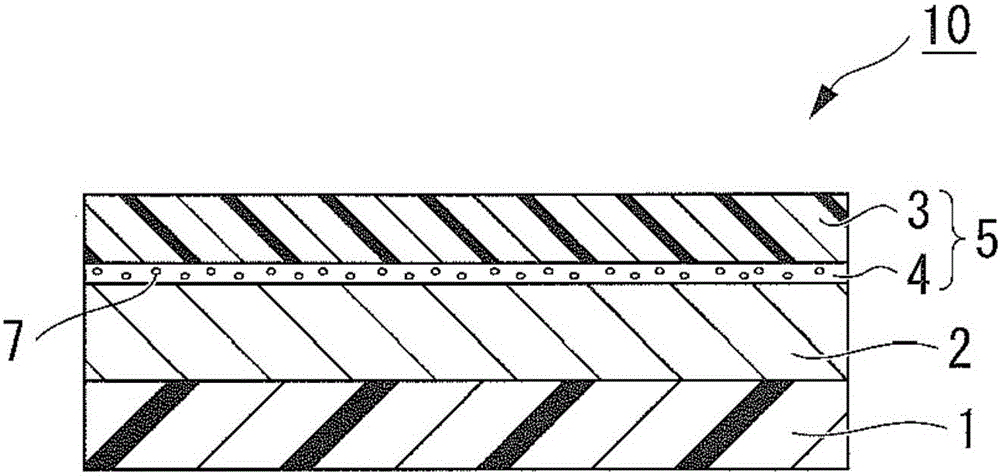

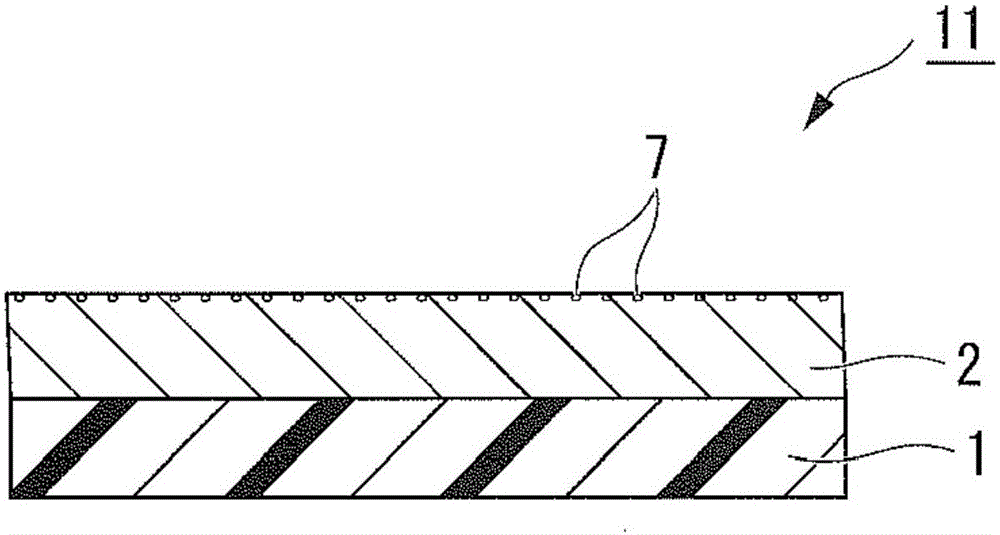

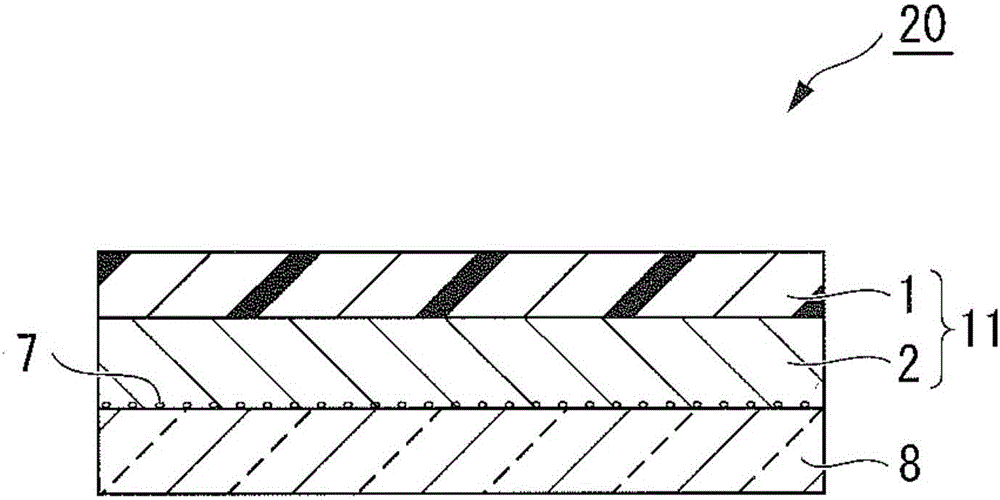

[0094] (Preparation of surface protection film)

[0095] 5 parts by weight of addition reaction silicone (manufactured by Dow Corning Toray Co., Ltd., trade name: SRX-345), 0.75 parts by weight of lithium bisfluorosulfonyl imide, 0.75 parts by weight of tetraethylene glycol di- 2-Ethylhexanoate, 95 parts by weight of a 1:1 mixed solvent of toluene and ethyl acetate, and 0.05 parts by weight of a platinum catalyst (manufactured by Dow Corning Toray Co., Ltd., trade name: SRX-212) were mixed and stirred Mixed to prepare a paint for forming the release agent layer of Example 1. On the surface of a polyethylene terephthalate resin film with a thickness of 38 μm, the paint forming the release agent layer of Example 1 was coated with a Meyer bar so that the thickness after drying was 0.2 μm, and hot air at 120° C. was used. Drying was performed for 1 minute in a circulating oven to obtain the release film of Example 1.

[0096] On the other hand, compared to the copolymer formed b...

Embodiment 2

[0099] The surface protection film of Example 2 was obtained in the same manner as in Example 1, except that the thickness after drying of the paint forming the release agent layer of Example 1 was 0.1 μm.

Embodiment 3

[0101] In addition to changing the addition reaction type silicone in Example 1 to Dow Corning Toray Co., Ltd. product name: SRX-211, and changing lithium bisfluorosulfonyl imide to lithium bistrifluoromethanesulfonyl imide, The surface protection film of Example 3 was obtained in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com