System and method for quickly treating pulverized coal by pyrolysis

A fast, pulverized coal technology, applied in the field of pulverized coal pyrolysis, can solve problems that have not been used in large-scale industrialization, and achieve the effects of high economic value, simple system structure, and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

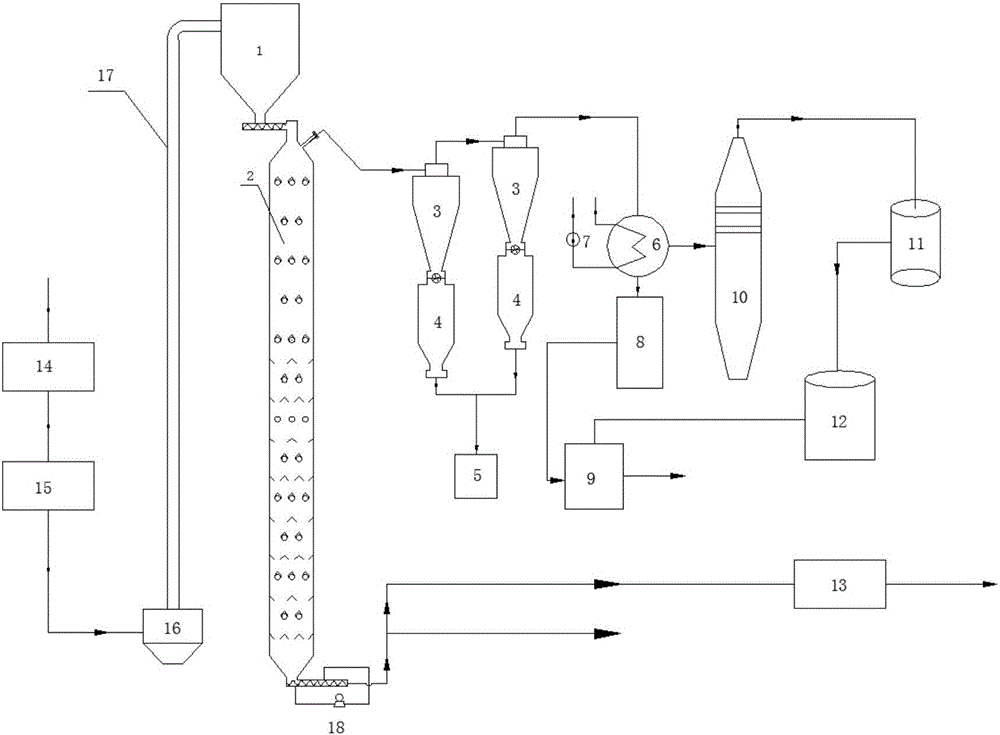

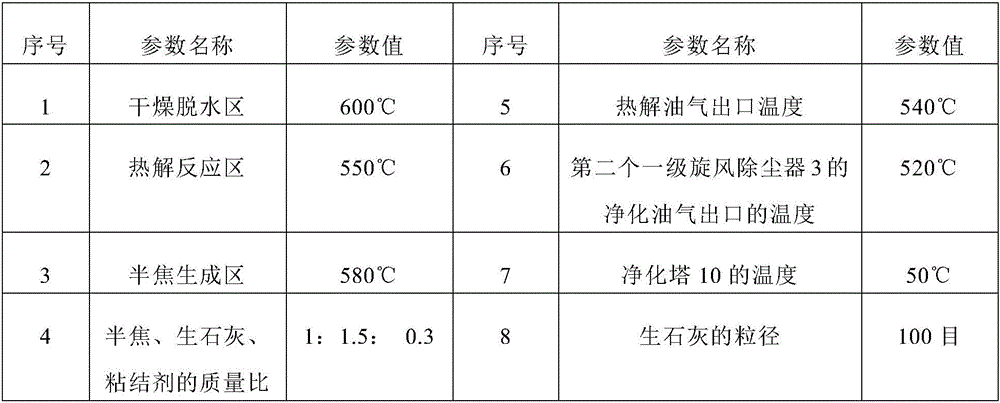

[0067] use figure 1 The system shown processes Ito lignite. In reactor 2, the opening angle of the baffle assembly composed of two baffles with the opening downward is 70°, the angle formed between the baffle plate and the inner wall of the reactor body is 40°, and the top angle of the top cover is 70° , the width of the vertical section of the top cover is 330mm, the length of the baffle is 450mm, the radiant tubes are circular tubes with a nominal diameter of 300mm, the horizontal distance between the left and right adjacent radiant tubes is 400mm, and the vertically adjacent The vertical distance between the two radiant tubes is 1200mm. The height of the reactor body is 20m, the width of the inner wall is 6m, the length of the inner wall is 15m, and there are 25 layers of radiant tubes.

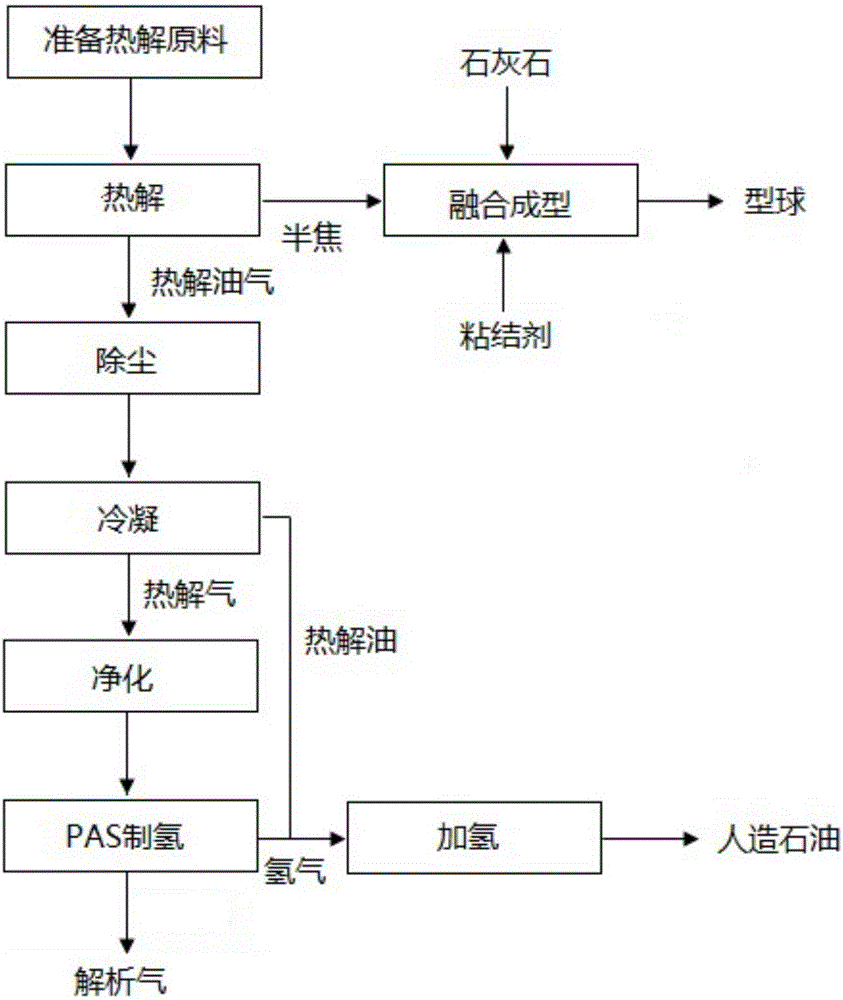

[0068] The component analysis of the Ito lignite is shown in Table 1, and its particle size is ≤1mm. The pyrolysis process is as figure 2 As shown, the details are as follows:

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com