Dark fermentation-light fermentation coupled biological hydrogen preparing process

A technology for biological hydrogen production and photofermentation, applied in the direction of fermentation, microorganisms, and methods based on microorganisms, can solve the problems of increasing floor area and processing steps, limiting large-scale production of coupled biohydrogen, and low substrate utilization. Achieve the effects of improving substrate utilization, improving coupled hydrogen production efficiency, and releasing inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

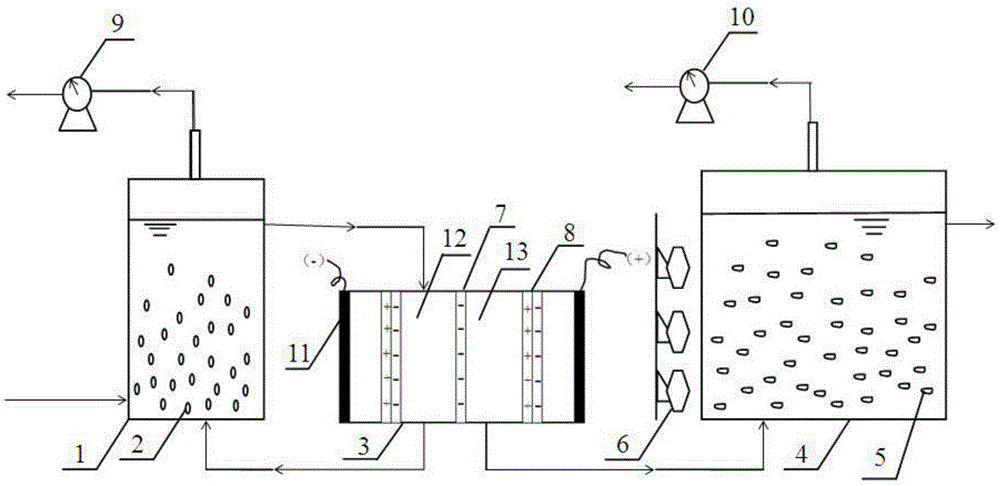

Image

Examples

Embodiment 1

[0030] A dark-light fermentation coupled biological hydrogen production process, comprising the following steps:

[0031] A. Add medium to the dark fermentation reactor and light fermentation reactor respectively, use nitrogen and argon to aerate the dark fermentation reactor and light fermentation reactor for 10 minutes to remove the air in the reactor, and then cover and seal to maintain anaerobic environment;

[0032] B, in the substratum of dark fermentation reactor, be 10% to insert dark fermentation bacterium by inoculation volume ratio;

[0033] C. In the culture medium of the photofermentation reactor, it is 10% to insert the photofermentation bacteria according to the inoculation volume ratio, and the light intensity of the light system is controlled to 150w / m2;

[0034] D. Place the dark-light fermentation coupled biohydrogen production system in a constant temperature room with a temperature of 33-35°C;

[0035] E. When the pH in the dark fermentation reactor drop...

Embodiment 2

[0046] A dark-light fermentation coupled biological hydrogen production process, comprising the following steps:

[0047] A. Add medium to the dark fermentation reactor and light fermentation reactor respectively, use nitrogen and argon to aerate the dark fermentation reactor and light fermentation reactor for 9 minutes to remove the air in the reactor, and then cover and seal to maintain anaerobic environment;

[0048] B, in the substratum of dark fermentation reactor, be 12% to insert dark fermentation bacterium by inoculation volume ratio;

[0049] C, in the culture medium of photofermentation reactor, insert photofermentation bacteria according to the inoculation volume ratio of 12%, control the light intensity of the light system to 120w / m2;

[0050] D. Place the dark-light fermentation coupled biohydrogen production system in a constant temperature room with a temperature of 33-35°C;

[0051] E. When the pH in the dark fermentation reactor drops to 4.3 to 4.6, load a D...

Embodiment 3

[0055] A dark-light fermentation coupled biological hydrogen production process, comprising the following steps:

[0056] A. Add medium to the dark fermentation reactor and light fermentation reactor respectively, use nitrogen and argon to aerate the dark fermentation reactor and light fermentation reactor for 15 minutes to remove the air in the reactor, and then cover and seal to maintain anaerobic environment;

[0057] B, in the culture medium of dark fermentation reactor, be 8% to insert dark fermentation bacterium by inoculation volume ratio;

[0058] C, in the culture medium of photofermentation reactor, it is 8% to insert photofermentation bacteria according to the inoculation volume ratio, and the light intensity of control lighting system is to 165w / m ;

[0059] D. Place the dark-light fermentation coupled biohydrogen production system in a constant temperature room with a temperature of 33-35°C;

[0060] E. When the pH in the dark fermentation reactor drops to 4.3 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com