Sandwich thermal insulation concrete outer wallboard with steel beam, steel diagonal bracings and outer wallboard body being prefabricated simultaneously and installation method of sandwich thermal insulation concrete outer wallboard

A technology of thermal insulation concrete and exterior wall panels, applied in the processing of building materials, building components, construction, etc., can solve the problems of poor sealing, high cost, slow installation speed, etc., to reduce wet work, protect the environment, and speed up construction fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with embodiment, further illustrate the present invention.

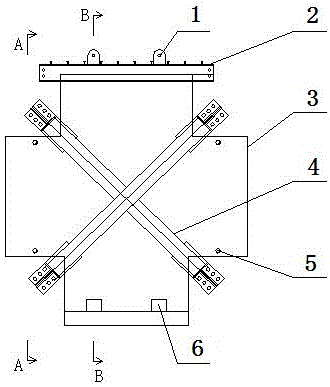

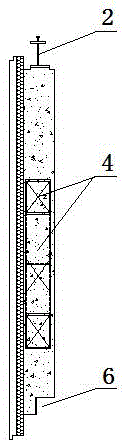

[0027] see figure 1 , figure 2 , image 3 , a sandwich insulation concrete exterior wall panel prefabricated simultaneously with steel beams, steel diagonal supports and exterior wall panels, consisting of exterior wall panels 3, steel beams 2, and steel diagonal supports 4; the exterior wall panels 3 are rectangular, and the exterior wall panels 3 There are connecting platforms at the four corners, the steel diagonal supports 4 are arranged crosswise in the exterior wall panels 3, and the four ends of the steel diagonal supports 4 are arranged at the connection platforms; the steel beams 2 are arranged on the top of the external wall panels 3. There are four flat hanging holes 5, and the flat hanging holes 5 are symmetrically arranged on both sides of the outer wall panel 3. Through four flat hanging holes 5, the device can be hoisted horizontally.

[0028] see Figure 4 , Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com