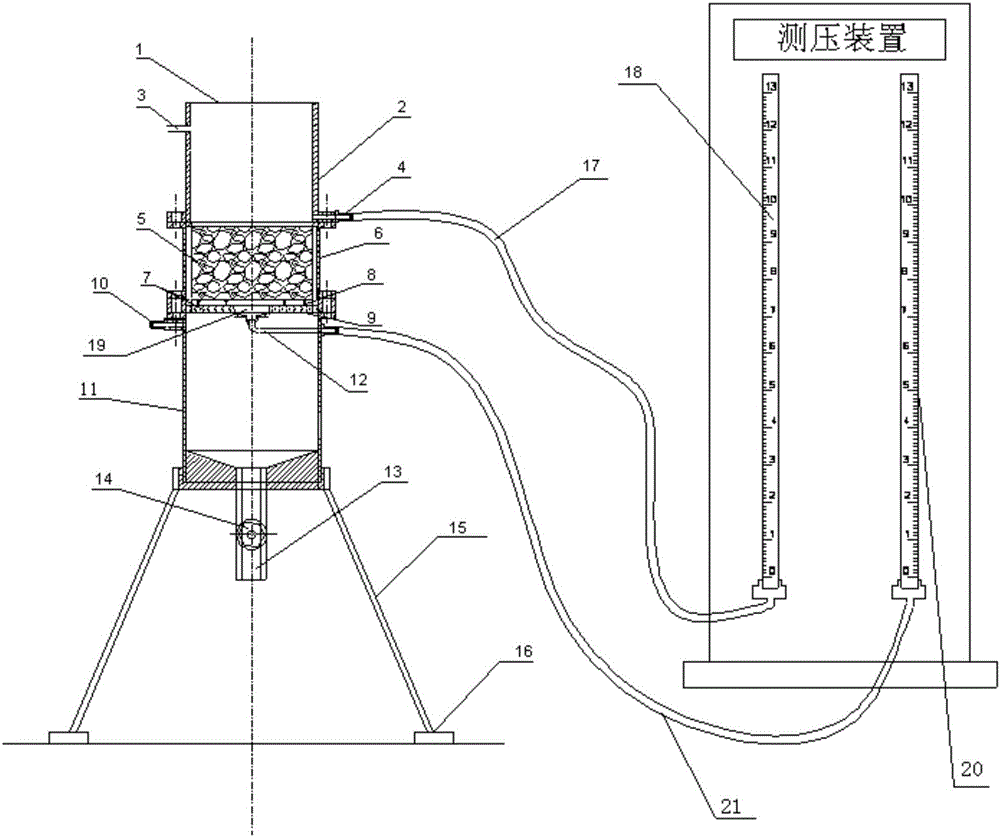

Water seepage meter and method for measuring large gap pavement structure multidirectional permeability coefficients

A technology of permeability coefficient and pavement structure, applied in permeability/surface area analysis, instruments, measuring devices, etc., can solve the problems of unstable test results, difficult water head height, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Example 1: Determination of comprehensive permeability coefficient of single-layer asphalt mixture specimen compacted indoors

[0068] Step 1: According to the design gradation and design asphalt dosage, the passing rate of aggregates with different particle sizes is as follows: 16mm:9.5mm:4.75mm:2.36mm:1.18mm:0.6mm:0.3mm:0.15mm:0.075mm= 100:95.3:61.6:23.3:16.3:13.2:10.7:8.8:7.4:5.4, the design asphalt dosage is 4.58%. The asphalt and aggregates were mixed at 180°C, and a test piece with a diameter of 100 mm and a height of 63.5 mm was formed by a rotary compactor, and the rotary compactor was rotated and compacted 50 times. After the test piece is formed, keep it warm at 20°C for 24 hours before use. According to the measured height H and diameter D of the test piece, the calculated cross-sectional area A of the test piece is 7853.98mm 2 .

[0069] Step 2: Connect the middle mold barrel 6 and the lower mold barrel 11 with a coaxial seal, a rubber sealing ring is san...

Embodiment 2

[0077] Example 2: Determination of vertical permeability coefficient of single-layer asphalt mixture specimen compacted indoors

[0078] Step 1: Connect the middle mold barrel 6 and the lower mold barrel 11 in a coaxial sealing connection, with a rubber sealing ring clamped between the middle mold barrel 6 and the lower mold barrel 11, and tighten the middle mold barrel 6 and the lower mold barrel 11 with screws to ensure Water does not flow out of the gap. The diameter of middle die cylinder 6 is 103mm, and height is 63.5mm. The diameter of lower mold cylinder 11 is 103mm, and height is 100mm.

[0079] Step 2: Use the test piece as in Step 1 of Example 1, and apply Vaseline evenly on the side of the test piece with a spatula to seal the entire side of the test piece, and the coating thickness is 0.8 mm to 1 mm. During the application process, prevent petroleum jelly from being applied to the upper and lower surfaces of the test piece. Put the smeared test piece into the mi...

Embodiment 3

[0081] Example 3: Determination of lateral permeability coefficient of single-layer asphalt mixture specimen compacted indoors

[0082] Steps 1-2: Same as Steps 1-2 in Example 1.

[0083] Step 3: Apply Vaseline evenly on the lower surface of the test piece with a spatula, and seal the entire lower surface of the test piece with a thickness of 0.8 mm to 1 mm. During the application process, prevent petroleum jelly from spreading to the sides of the test piece. After the smearing is completed, the test piece is placed on the porous water-permeable plate 9 in the middle mold barrel 6 .

[0084] Steps 4-9: Same as Steps 4-9 in Example 1, the measured transverse permeability coefficient is 0.296 cm / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com