A kind of fuel rod end plug corking machine and using method

A rod-end plugging machine and fuel rod technology, which is applied in the manufacture of reactors, reactors, and greenhouse gas reduction, can solve problems such as low efficiency, increased costs, and poor sealing, and achieve convenient operation, easy adjustment, and stable connection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

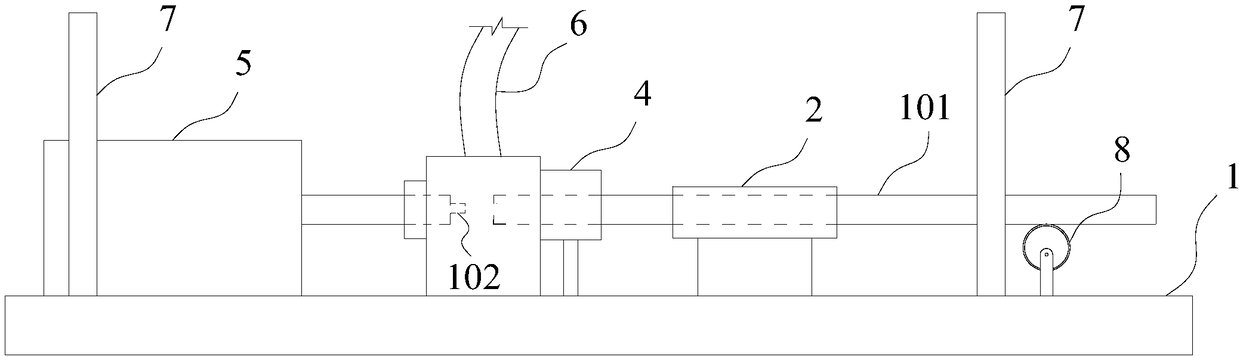

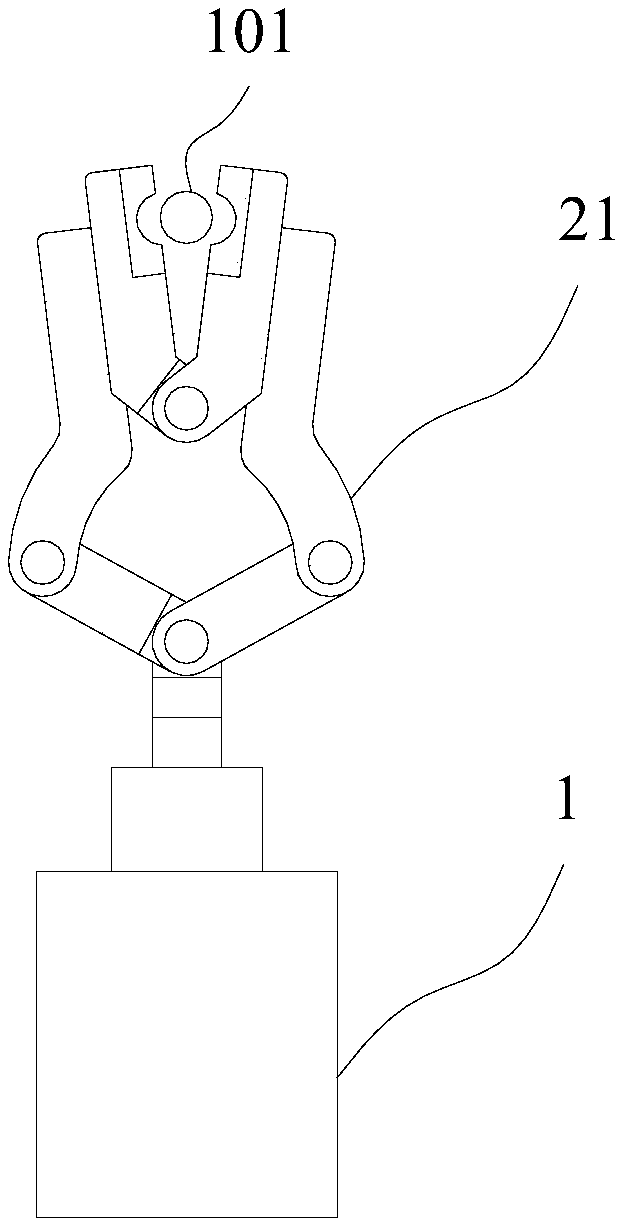

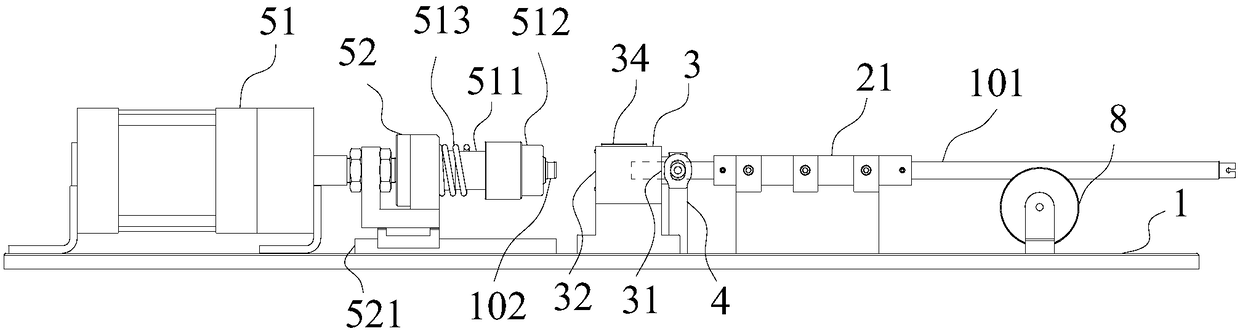

[0059] Such as figure 1 As shown, a fuel rod end plug corking machine includes a base 1, a drive system and a control system, and a fixing mechanism 2, an operating room 3, a sealing mechanism 4 and a pushing mechanism 5 are all arranged on the base 1, giving The exhaust mechanism 6 is connected to the operating room 3, the control system controls the driving system to drive the pushing mechanism and the supply and exhaust mechanism, the fixing mechanism 2 is used to fix the fuel rod 101, and the base 1 There is also a support wheel 8 for supporting the other end of the plugging end of the fuel rod 101 to prevent the cladding tube from being damaged due to the rod body being too long and falling under gravity. The sealing mechanism 4 is located in the operating room 3 On one side, the plugging end of the fuel rod 101 extends into the operation chamber 3 through the sealing mechanism 4, and the pushing mechanism 5 is located on the opposite side of the sealing mechanism 4, and ...

Embodiment 2

[0062] A method for using a fuel rod end plug corking machine, comprising using a fuel rod end plug corking machine as in Embodiment 1, the method of use comprising the following steps:

[0063] Step 1. Put the plugging end of the fuel rod 101 through the sealing mechanism 4 and put it into the operation chamber 3;

[0064] Step 2, using the sealing mechanism 4 to seal the plugging end of the fuel rod 101;

[0065] Step 3, fixing the fuel rod 101 with the fixing mechanism 2;

[0066] Step 4, put the end plug 102 into the push mechanism 5 and fix it;

[0067] Step 5, the pushing mechanism 5 and the sealing mechanism 4 are adapted to the operating chamber 3, and the operating chamber 3 is formed into a closed cavity;

[0068] Step 6, the air supply and exhaust mechanism 6 vacuumizes the cavity;

[0069] Step 7, the air supply and exhaust mechanism 6 fills the cavity with inert gas;

[0070] Step 8: The pushing mechanism 5 presses the end plug 102 into the plugging end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com