Preparation method of vanadium-molybdenum-doped lithium ion battery cathode material

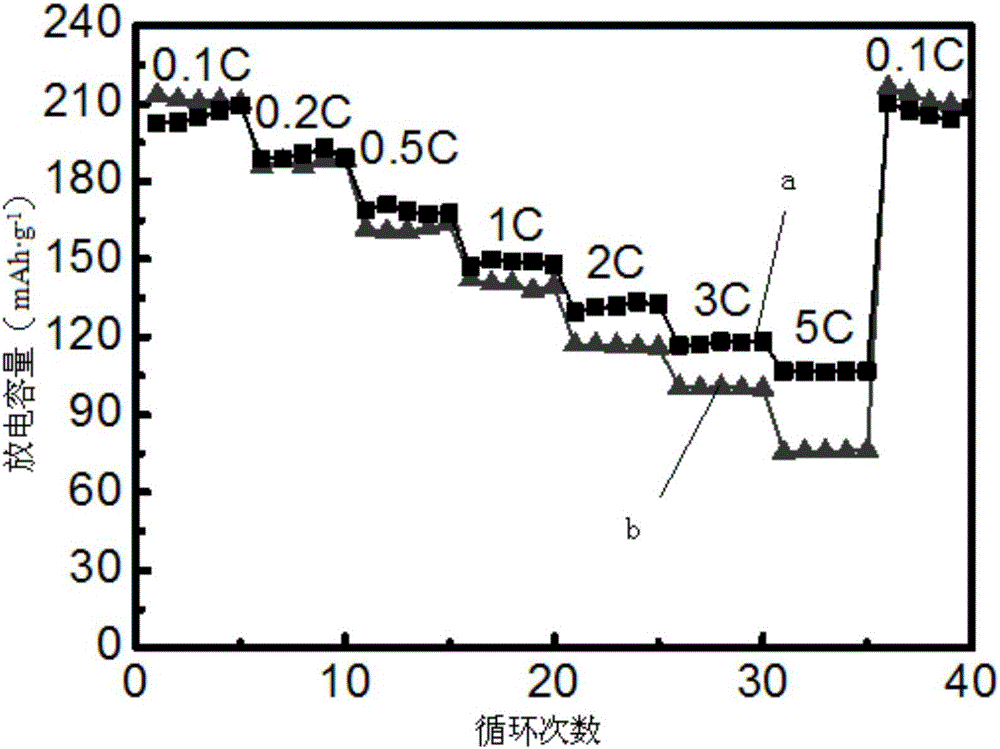

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor cycle stability of lithium-ion batteries, and achieve good rate discharge performance, uniform crystal particles, and good reversibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

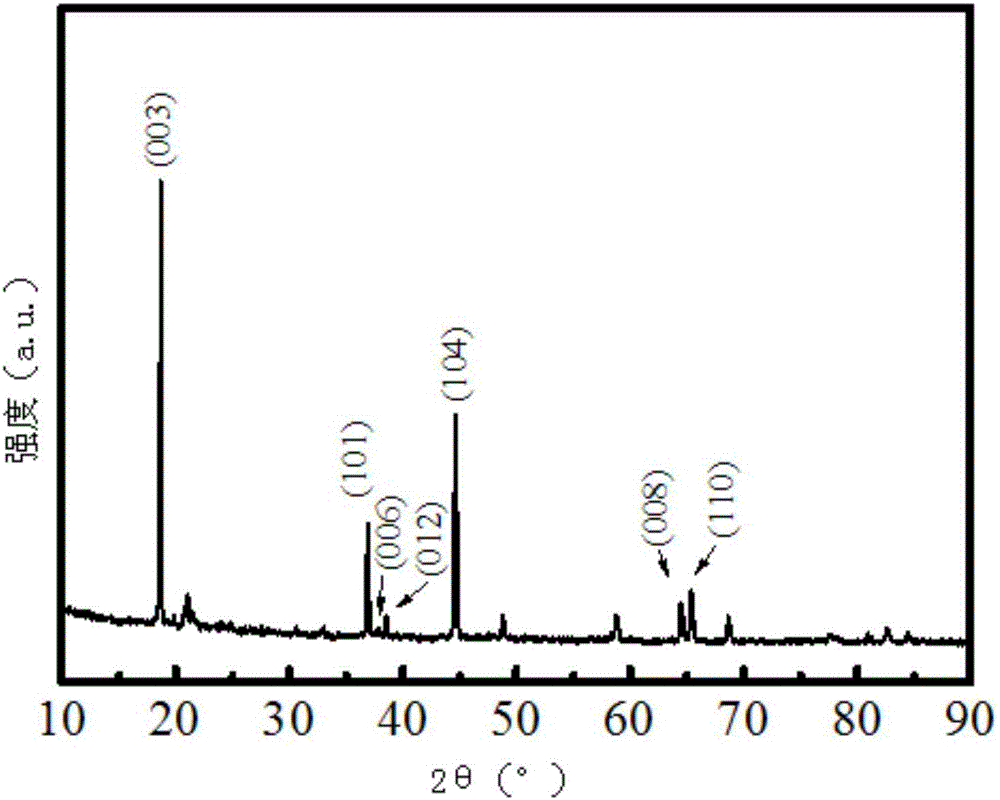

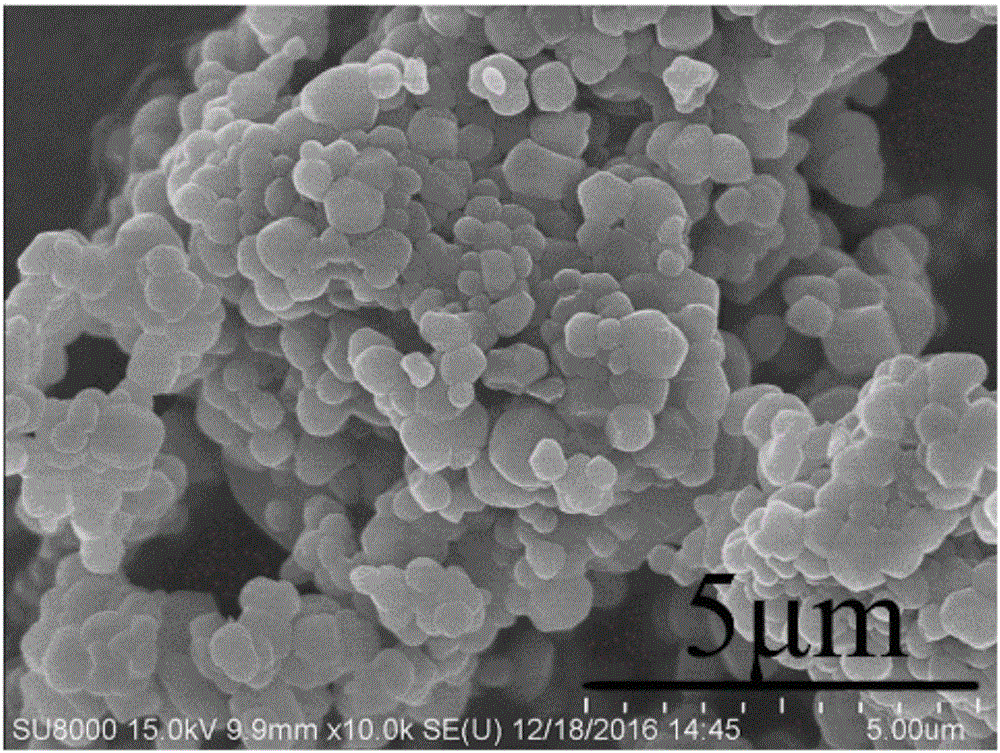

[0025] Specific embodiment one: the preparation method of a kind of vanadium, molybdenum doped lithium-ion battery cathode material of this embodiment is carried out according to the following steps:

[0026] 1. According to the chemical formula Li 1.2 mn 0.54-x-y co 0.13 Ni 0.13 V x Mo y o 2 The molar ratio of Li element to Mn element is 1.2:0.54-x-y, the molar ratio of Li element to Co element is 1.2:0.13, the molar ratio of Li element to Ni element is 1.2:0.13, and the molar ratio of Li element to V element The molar ratio of x, Li element and Mo element is 1.2:y and the molar ratio of Li element and complexing agent is 1.2:2, and lithium source, manganese source, cobalt source, nickel source, vanadium source, molybdenum source Mix with a complexing agent, then dissolve in deionized water to obtain a mixed solution;

[0027] x=0.01~0.03, y=0.01~0.03 described in step 1;

[0028] The ratio of the sum of the amounts of Li, Mn, Co, Ni, V, Mo and the complexing agent to...

specific Embodiment approach 2

[0031] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the lithium source described in step one is Li 2 CO 3 and LiCH 3 COO·H 2 One of O or a mixture of both. Other steps and parameters are the same as those in the first embodiment.

[0032] In this embodiment, when the lithium source is a mixture, various lithium sources can be combined in any ratio.

specific Embodiment approach 3

[0033] Specific embodiment three: the difference between this embodiment and one of the specific embodiments one to two is: the vanadium source described in step one is V 2 o 5 and NH 4 VO 3 one or a mixture of both. Other steps and parameters are the same as those in the specific embodiment 1 to 2.

[0034] In this embodiment, when the vanadium source is a mixture, various vanadium sources can be combined in any ratio.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com