Low-cost flow battery negative electrode electrolyte and preparation method therefor

An anode electrolyte and flow battery technology, which is applied in the field of low-cost flow battery anode electrolyte and its preparation, can solve the problems of restricting the large-scale use of flow batteries, high cost of use, limited earth storage, etc. The effect of a wide range of applications, cost reduction, and low performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Weigh 28.05g KOH into a 250ml beaker, add appropriate amount of deionized water, stir to a constant volume of 500ml, weigh 0.6g1,8-DHAQ into a 250ml beaker, add an appropriate amount of 1M KOH solution, stir to a constant volume of 250ml, and then prepare The low-cost liquid flow battery negative electrode electrolyte of the present invention is composed of 0.01 mol / l 1,8-DHAQ and 1.0 mol / l KOH.

Embodiment 2

[0017] Weigh 28.05g KOH into a 250ml beaker, add appropriate amount of deionized water, stir to a constant volume of 500ml, weigh 6g of 1,8-DHAQ into a 250ml beaker, add an appropriate amount of 1M KOH solution, stir to a constant volume of 250ml, and then prepare this product The negative electrode electrolyte of the low-cost liquid flow battery described in the invention is composed of 0.1 mol / l 1,8-DHAQ and 1.0 mol / l KOH.

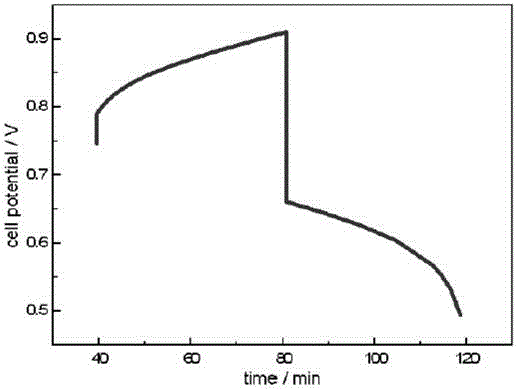

[0018] Adopt the low-cost liquid flow battery negative electrode electrolyte that embodiment 2 gains and K 4 Fe(CN) 6 Assembled into a flow battery, the flow rate of both positive and negative electrodes is 60ml / min. Put the flow battery at 100mA / cm 2 The charge and discharge test is completed at a current density of figure 1 is 1,8-DHAQ / K 4 Fe(CN) 6 The charge and discharge test curve of the flow battery.

Embodiment 3

[0020] Weigh 56.1g of KOH into a 250ml beaker, add appropriate amount of deionized water, stir to a constant volume of 500ml, weigh 60g of 1,8-DHAQ into a 250ml beaker, add an appropriate amount of 2M KOH solution, and stir to a constant volume of 250ml to prepare this product The low-cost liquid flow battery negative electrode electrolyte described in the invention is composed of 1 mol / l 1,8-DHAQ and 2.0 mol / l KOH.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com