Same-phase traction power supply system suitable for high-speed electrified railway

A traction power supply system and electrified railway technology, applied in the field of in-phase traction power supply technology system, can solve the problems of high construction cost, high overall investment and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The following is a detailed description of a co-phase traction power supply system suitable for high-speed electrified railways proposed by the present invention in combination with the drawings and embodiments as follows:

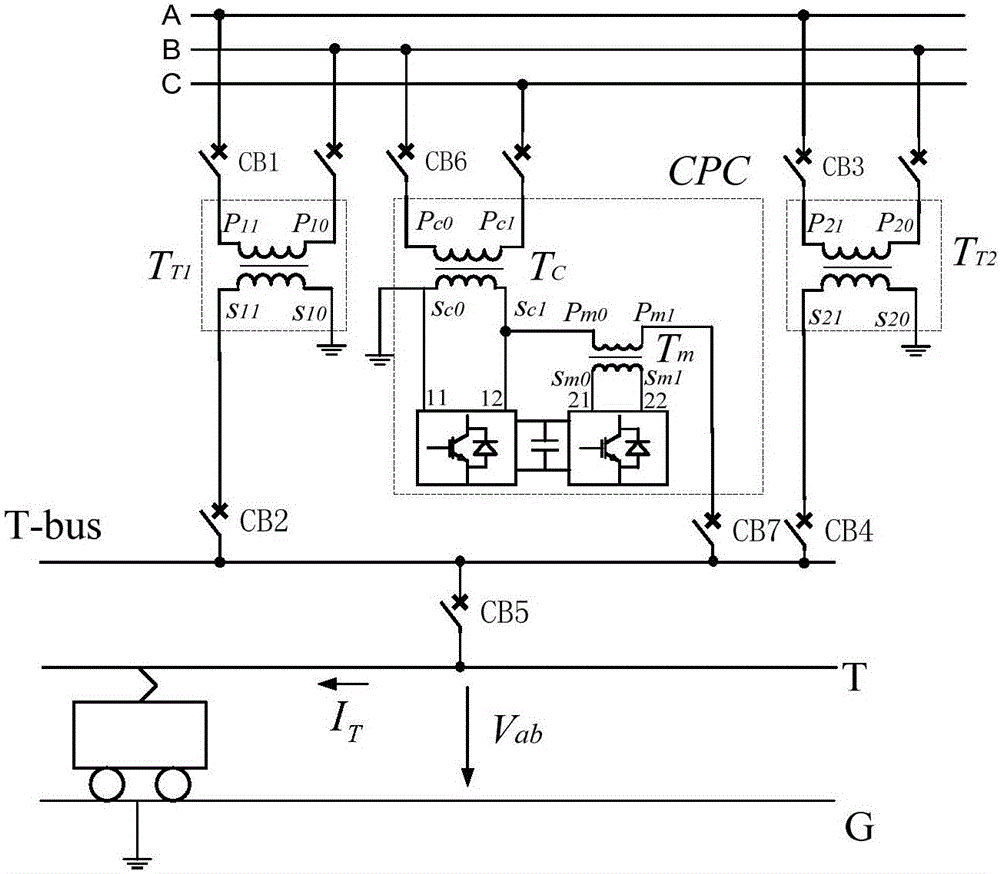

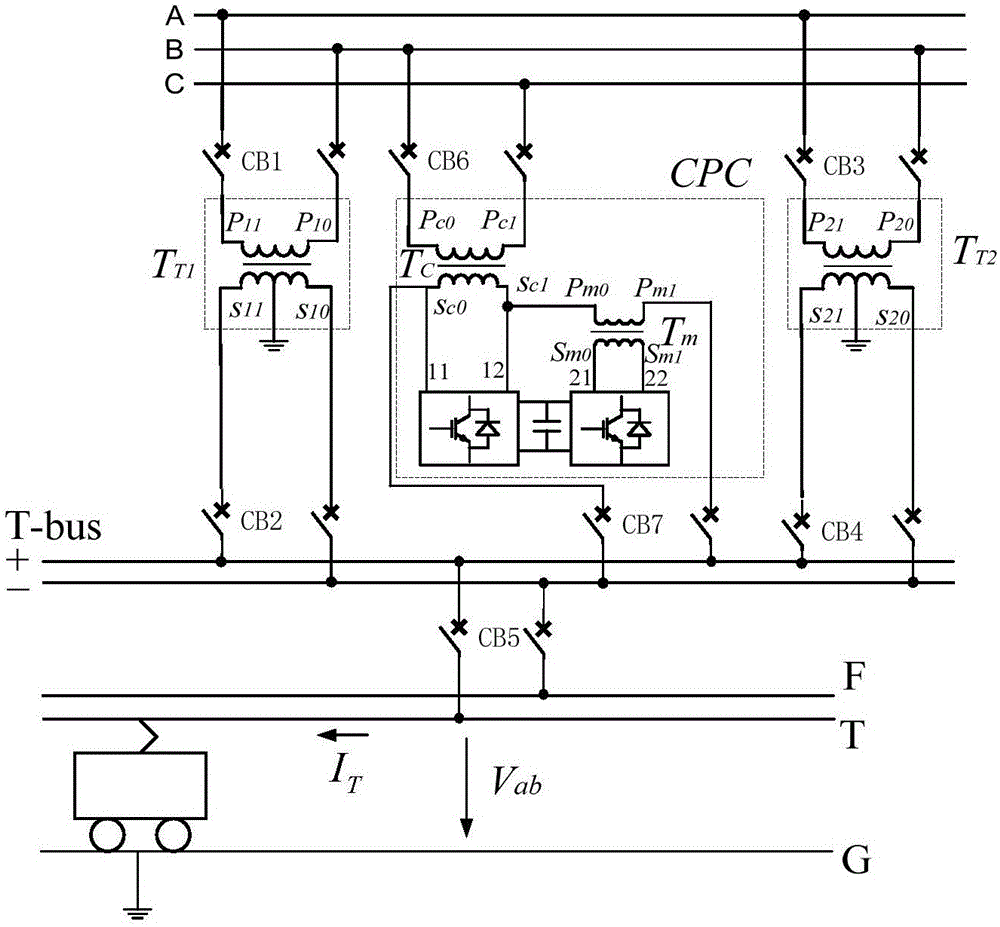

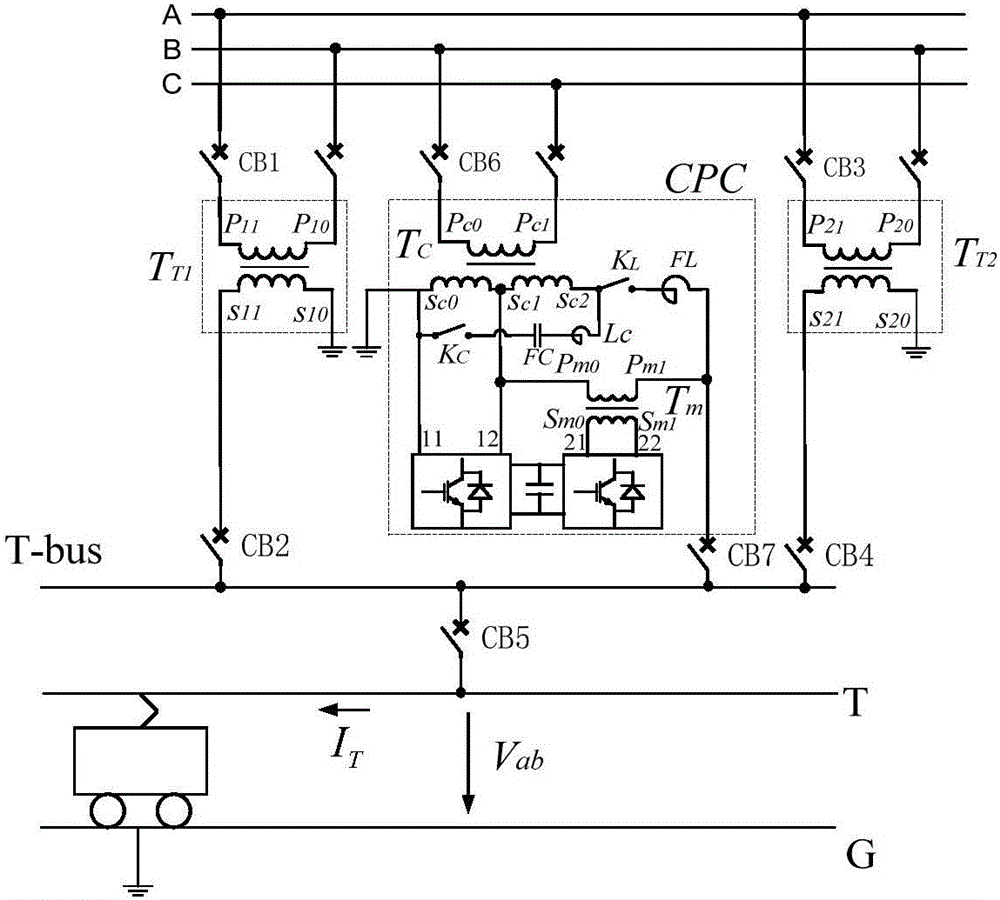

[0043] The present invention proposes a co-phase power supply system suitable for high-speed electrified railways. When the system is a direct power supply system and adopts an active compensation configuration, its structure diagram is as follows figure 1 Shown, including main traction transformer T T1 , Spare traction transformer T T2 And the in-phase compensator CPC; the in-phase compensator CPC is an active compensation configuration mode, which is composed of a compensation transformer T C , "Back-to-back" converter and matching transformer T m Composition; main traction transformer T T1 , Spare traction transformer T T2 , Compensation transformer T in the in-phase compensator CPC C , Matching transformer T m All are single-phase transformer structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com