A hollow cup motor rotor baking device

A technology for motor rotors and baking devices, which is applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of occupying the operating time of operators, increasing the temperature of operators, and scalding, so as to reduce production costs and maintain operations. The effect of improving safety and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

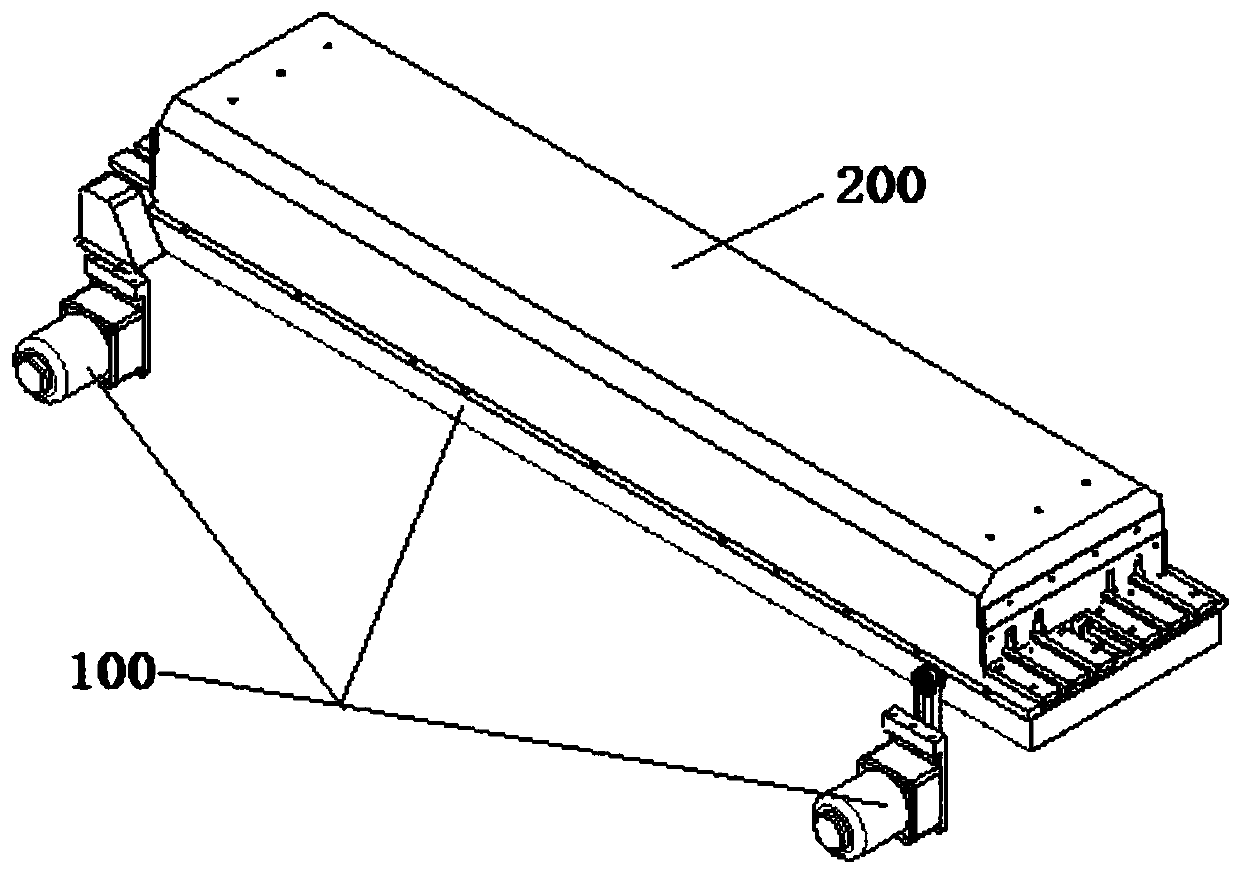

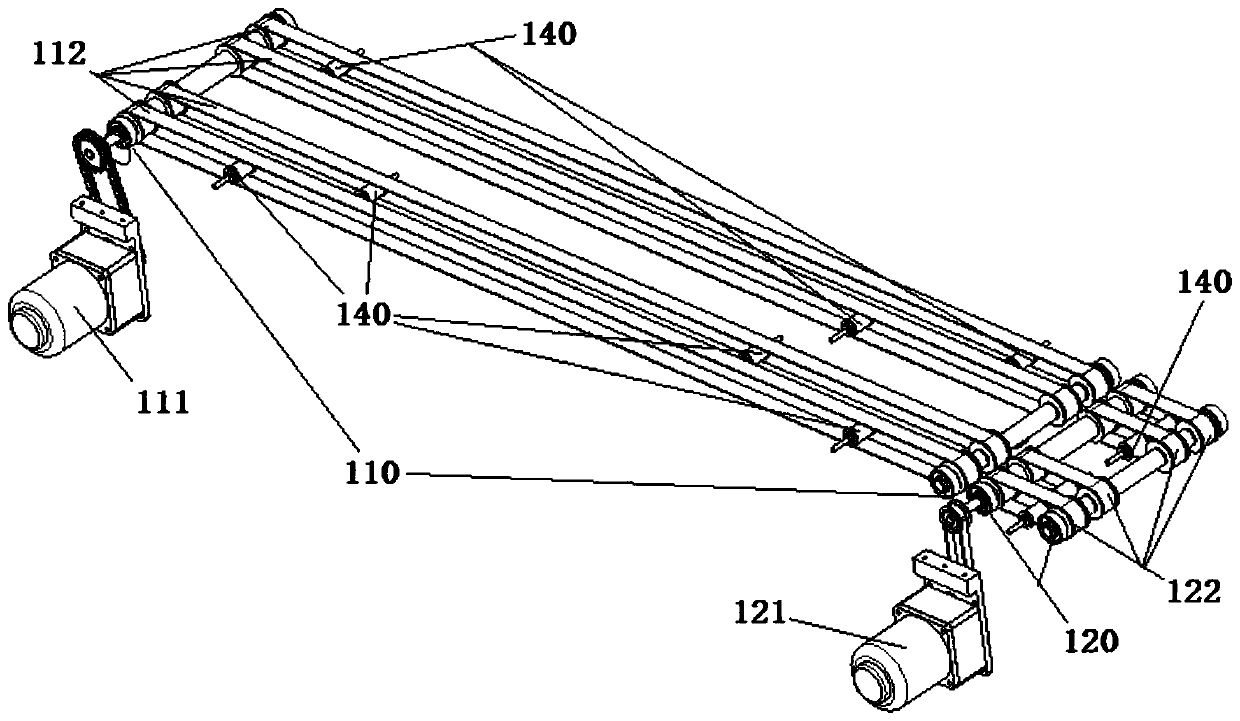

[0035] Such as Figure 2-5 As shown, the present invention provides a hollow-cup motor rotor baking device, including: a hollow-cup motor rotor conveyor 100 and a heat shield 200 buckled on the hollow-cup motor rotor conveyor; the hollow-cup motor rotor conveys The machine 100 includes a baking conveying section 110 and a feeding conveying section 120. The conveying speed of the baking conveying section 110 is lower than the conveying speed of the feeding conveying section 120; the heat shield 200 is provided with baking heating Device 210; the size of the heat shield 200 is adapted to the shape of the baking conveying section 110; the heat shield 200 is perpendicular to the conveying direction of the hollow-cup motor rotor conveyor at both ends are respectively provided with inlet Material port 201 and discharge port 202.

[0036] image 3 As shown, the baking conveying section 110 of the conveyor 100 is provided with a first driving motor 111 and a plurality of baking conveyin...

Embodiment 2

[0042] Image 6 As shown, in this embodiment, on the basis of Embodiment 1, a temperature detection device 132 is provided in the baking conveying section. By setting the temperature detection device in the baking conveying section, the present invention helps to achieve the technical effect of adjusting different baking temperatures for different components of the glue. The temperature detection device arranged in the baking conveying section can instantly feedback the insulation The instant temperature of the baking temperature field in the heat hood provides strong structural support for accurately baking the hollow cup motor rotor at all times; further, the temperature detection device installed in the baking conveying section can also obtain additional monitoring baking heating devices The technical effect of whether it is working normally helps to detect equipment failures in time, and then achieve the technical effect of timely stop loss.

[0043] Preferably, such as Imag...

Embodiment 3

[0046] Figure 7 As shown, the structural diagram of the heat shield placed upside down in this embodiment, this embodiment is based on the above-mentioned embodiment, the upper end surface of the heat shield 200 is provided with a number of air supply devices 220 in a uniformly distributed form The air supply device 220 includes: a ventilation plate 221, a wind cover 222 and a fan 223; the ventilation plate 221 is inlaid on the upper end surface of the heat shield, the ventilation plate is evenly distributed with ventilation holes; the wind One end of the cover 222 is firmly connected to the ventilation plate 221, and the other end of the wind cover 222 is fixedly provided with the fan 223.

[0047] The present invention further disposes several air supply devices in a uniformly distributed form on the upper end surface of the heat shield, which helps to achieve the technical effect of uniformly pushing the heat generated by the baking heating device to the hollow cup motor rotor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com