Permanent magnet assisted bearingless synchronous reluctance motor

A synchronous reluctance motor, bearingless technology, used in synchronous machines, synchronous motors with stationary armatures and rotating magnets, synchronous machine parts, etc., can solve the problem of low salient pole ratio, low torque density, motor power Low factor, etc., to achieve the effect of increasing torque density, reducing system cost, and wide range of constant power speed regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

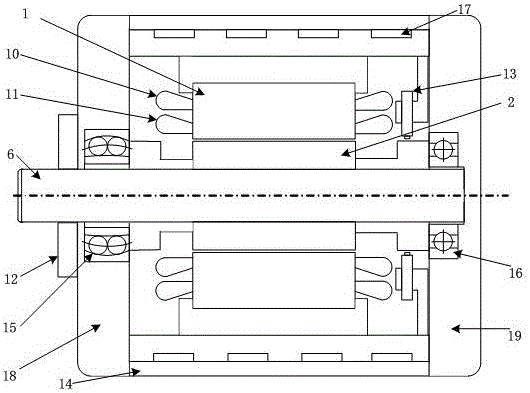

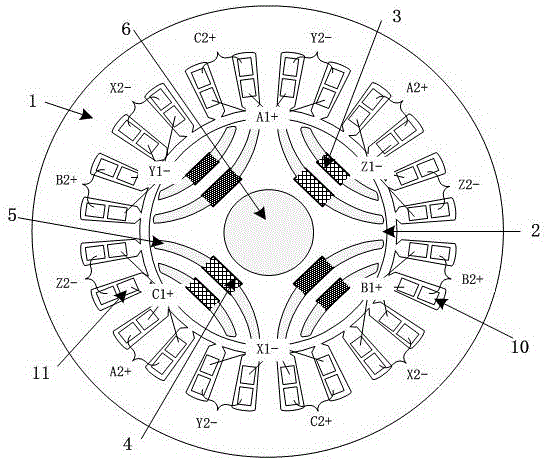

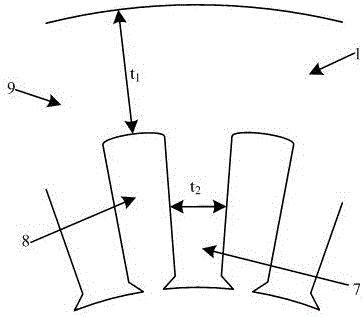

[0026] see figure 1 and figure 2 , the permanent magnet assisted bearingless synchronous reluctance motor of the present invention includes a stator 1, a rotor 2 and a rotating shaft 6, the rotor 2 is coaxially located inside the stator 1, the rotor 2 is coaxially sleeved outside the rotating shaft 6, and the rotor 2 is slotted for placement Spindle 6. The stator 1 is wound with inner and outer double-layer windings, the outer winding is a torque winding 10 , and the inner winding is a suspension force winding 11 . Outside the stator 1 is a casing 14, the left and right ends of the casing 14 are respectively a left end cover 18 and a right end cover 19, the casing 14 is used to fix the stator 1, the left end cover 18 and the right end cover 19, and the left end cover 18 passes through The self-aligning ball bearing 15 is connected to the rotating shaft 6 , and the right end cover 19 is connected to the rotating shaft 6 through the auxiliary bearing 16 . The self-aligning b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com