Preparation method of silver-loaded molecular sieve efficient antibacterial agent by solid-solid ion exchange

A technology of molecular sieve and antibacterial agent, which is applied in the field of solid-solid ion exchange to prepare silver-loaded molecular sieve high-efficiency antibacterial agent, which can solve the problems of low silver loading and low ion exchange rate, achieve high exchange rate, simple process, and promote application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

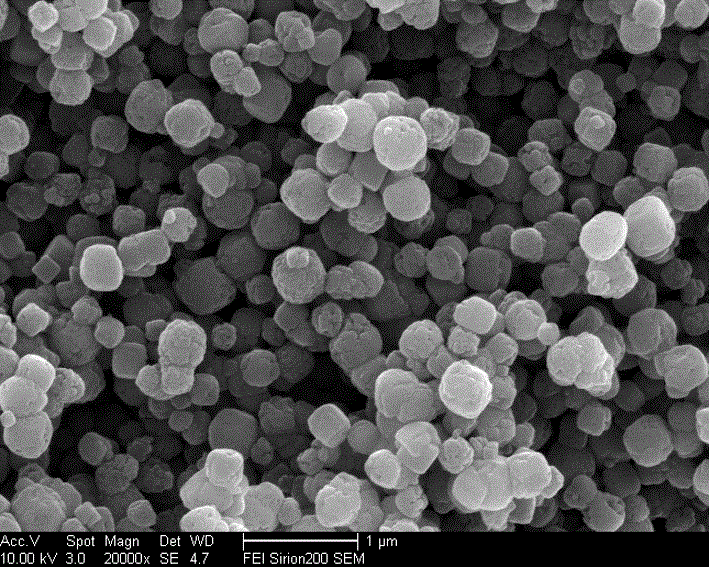

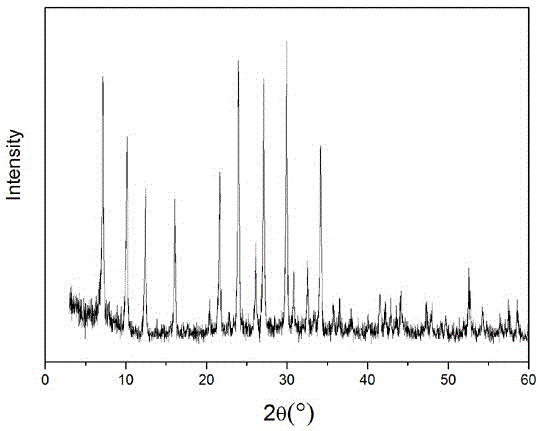

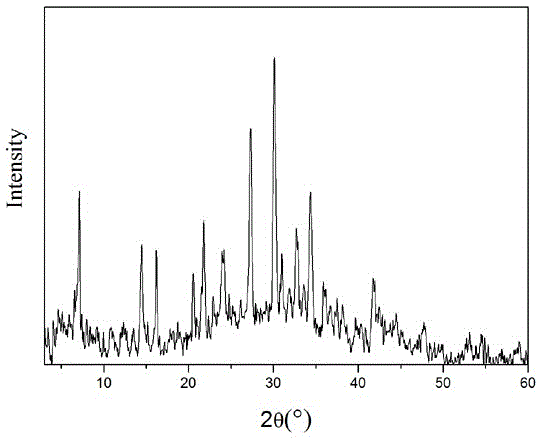

[0035] 100g of NaA molecular sieve with a median particle size of 200nm and 245g of NH 4 NO 3 Mix well, react in a high-temperature furnace at 250° C. for 1.5 h, and then fully wash with distilled water to obtain ammonium molecular sieves. The obtained ammonium molecular sieve was fully mixed with 312g of silver nitrate, reacted in a high-temperature furnace at 460° C. for 5 hours, and fully washed to obtain a silver-loaded NaA molecular sieve antibacterial agent. The silver-loaded NaA molecular sieve antibacterial agent has a silver-loaded content of 41.08% (mass ratio), and a minimum inhibitory concentration of 9.38ppm.

Embodiment 2

[0037] 100g of NaA molecular sieve with a median particle size of 300nm and 147g of NH 4 NO 3 Mix well, react in a high-temperature furnace at 150°C for 0.5h, and then fully wash with distilled water to obtain ammonium molecular sieves. The obtained ammonium molecular sieve is fully mixed with 104g of silver nitrate, reacted in a high-temperature furnace at 330°C for 1.5h, and fully washed to obtain a silver-loaded NaA molecular sieve antibacterial agent. The silver-loaded NaA molecular sieve antibacterial agent has a silver-loaded content of 28.15% (mass ratio), and a minimum inhibitory concentration of 20.84ppm.

Embodiment 3

[0039] 100g of NaA molecular sieve with a median particle size of 250nm and 196g of NH 4 NO 3 Mix well, react in a high-temperature furnace at 200°C for 1 hour, and then fully wash with distilled water to obtain ammonium molecular sieves. The obtained ammonium molecular sieve was fully mixed with 208g of silver nitrate, reacted in a high-temperature furnace at 395°C for 3.25h, and fully washed to obtain a silver-loaded NaA molecular sieve antibacterial agent. The silver-loaded NaA molecular sieve antibacterial agent has a silver-loaded content of 33.42% (mass ratio), and a minimum inhibitory concentration of 15.63ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com