Water-immersed self-cleaning cloth roller blind wet electrostatic precipitator

A dust collection device, wet electrostatic technology, applied in the field of dust removal, can solve the problems affecting the service life of the dust collector, uneven metal plate, dust collector failure, etc., to avoid uneven distribution of water film, improve space utilization, The effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

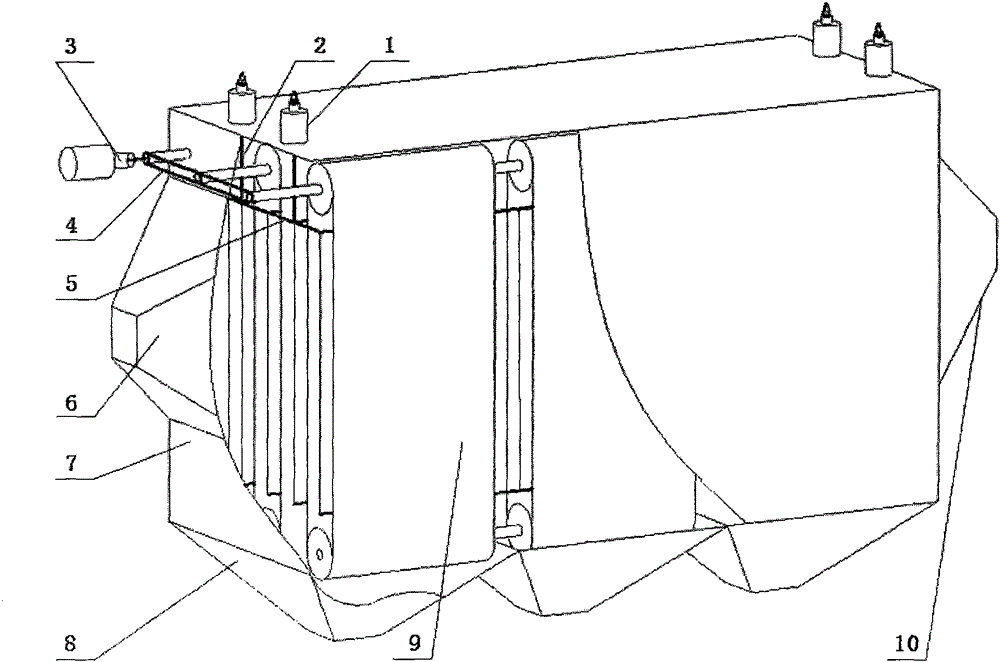

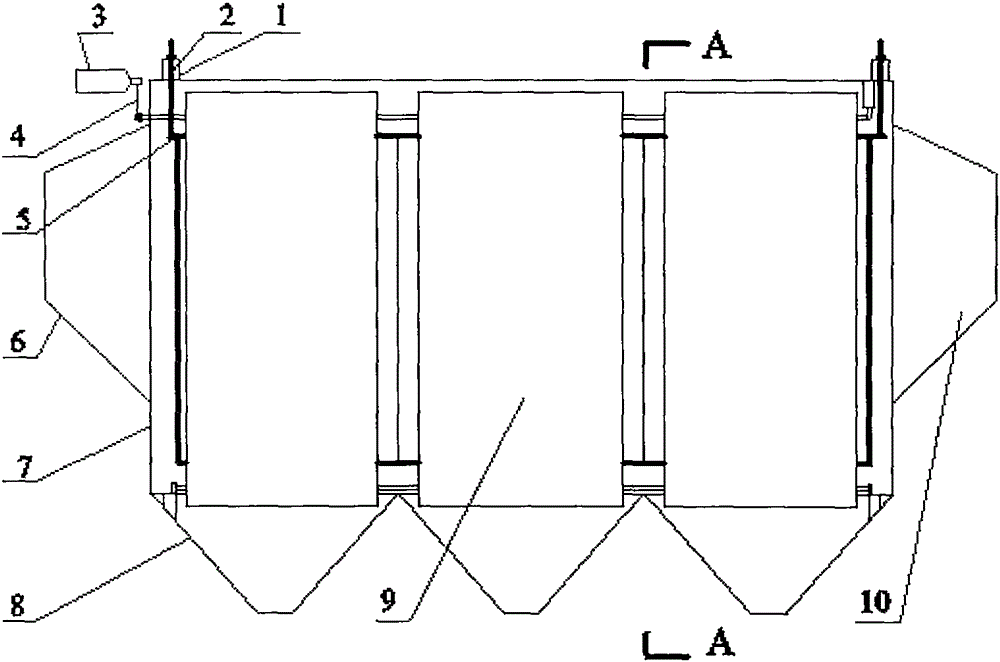

[0037] A water-immersed self-cleaning cloth roller blind wet electrostatic precipitator, such as figure 1 , figure 2 with image 3 As shown, it includes an air intake box 6 , a dust collection device body 7 , an air outlet box 10 and an ash hopper 8 .

[0038] The air intake box 6 is fixedly connected with the intake end of the dust collection device body 7 , the air outlet box 10 is fixedly connected with the gas outlet end of the dust collection device body 7 , and the bottom of the ash hopper 8 and the dust collection device body 7 is airtightly connected.

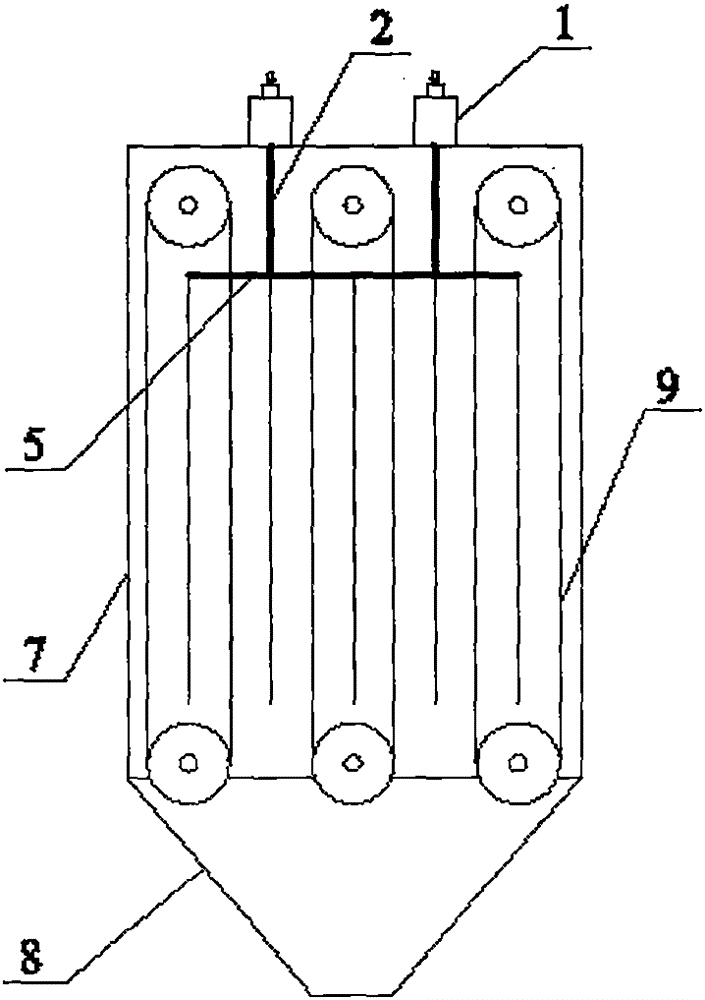

[0039] The dust collection device body 7 is composed of a corona pole wire frame 5, a pull rod terminal 2, a motor 3, a power transmission device 4 and three cloth roller shutter units 9 arranged in series.

[0040] The corona pole wire frame 5 is fixed on the top of the dust collecting device body 7 through the tie rod terminal 2 and the insulator 1 .

[0041] Such as image 3 , Figure 4 with Figure 5 As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com