Step type pore ZSM-5 zeolite and preparation method thereof

A technology of ZSM-5 and cascaded pores, which is applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of stability improvement and achieve strong acid strength and multi-acid active sites Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This embodiment provides a kind of stepped pore ZSM-5 zeolite, which is prepared through the following steps:

[0044] Mix 50g deionized water, 1.45g three polyquaternium C 16 C 6 C 6 C 16 Br 3 With 0.38g double-ended polyquaternium C 16 C 6 C 16 Br 2 Mix well to obtain a solution;

[0045] Add 0.7g of sodium hydroxide to the solution, stir evenly, add 0.6g of aluminum sulfate octadecahydrate, then add a mixture of 12.4g of ethanol and 8.2g of ethyl orthosilicate, stir at 40-60°C for 4-6h to obtain a condensate glue mixture;

[0046] The gel mixture was transferred to a polytetrafluoroethylene-lined stainless steel reactor, and hydrothermally crystallized at 150°C for 4 days;

[0047] The product obtained by hydrothermal crystallization was suction-filtered, washed with deionized water until pH<9, then dried at 120°C for 12h, and the dried sample was put into a muffle furnace for calcination at 550°C for 4h to obtain Na-type ZSM- 5 zeolites;

[0048] The Na-...

Embodiment 2

[0051] This embodiment provides a kind of stepped pore ZSM-5 zeolite, which is prepared through the following steps:

[0052] The preparation method is generally the same as in Example 1, the difference is that the template agent is replaced by 1.77g four-head cationic polyquaternary ammonium surfactant and 0.38g double-head cationic surfactant, and other conditions remain unchanged, and the prepared H-type The stepped pore ZSM-5 zeolite is denoted as Z-2.

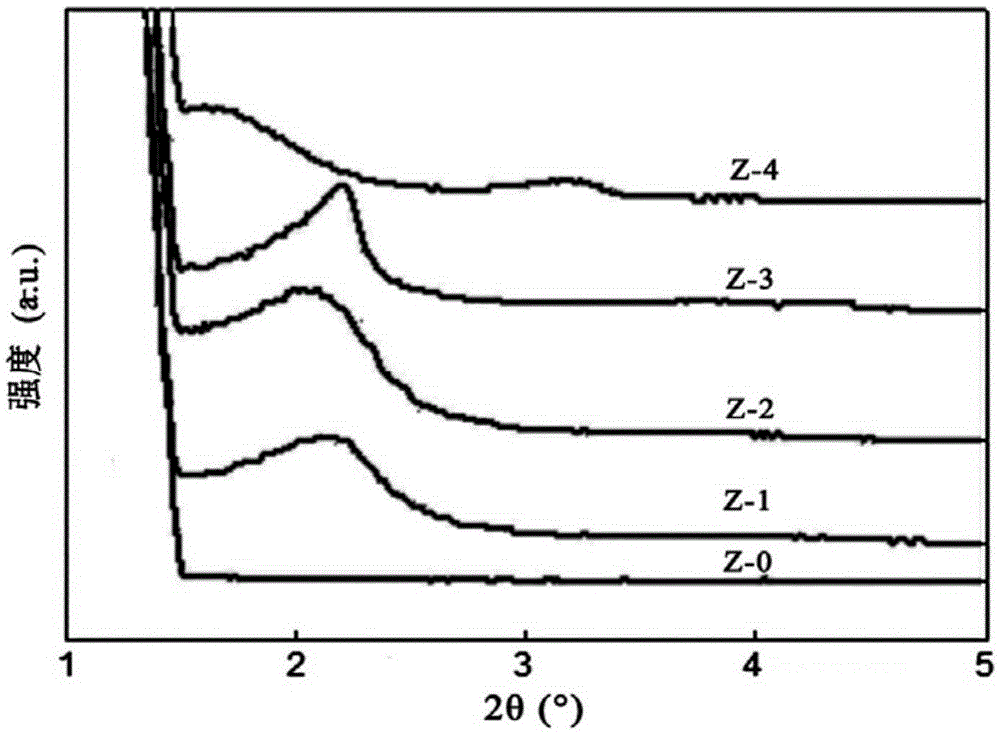

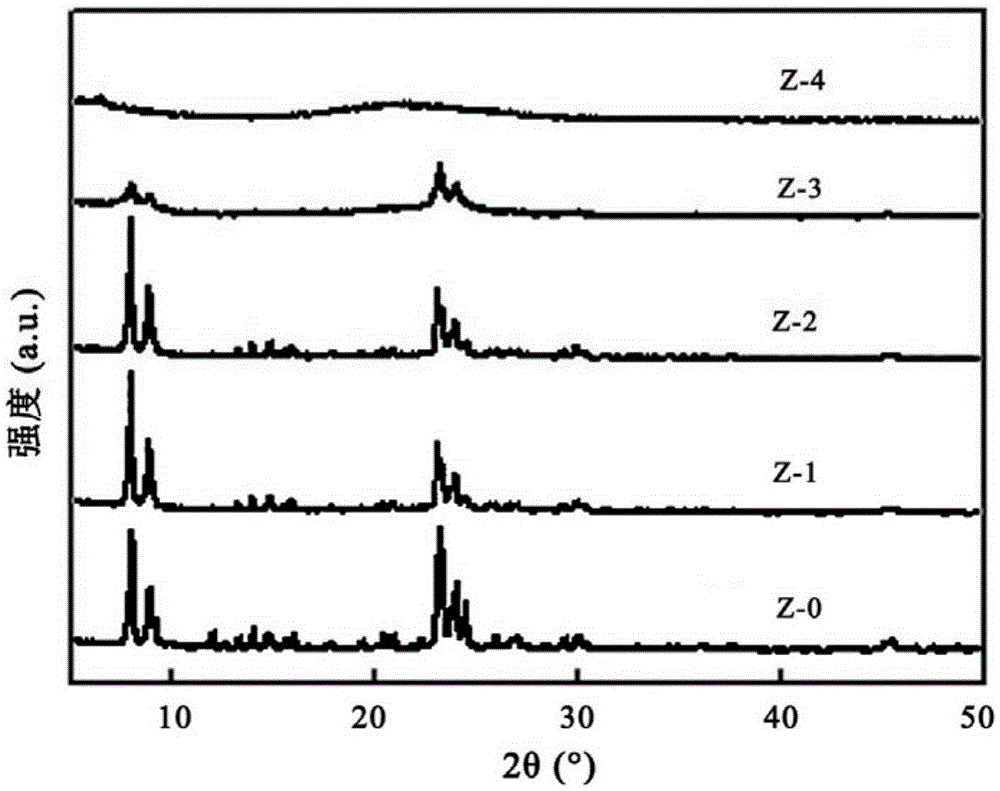

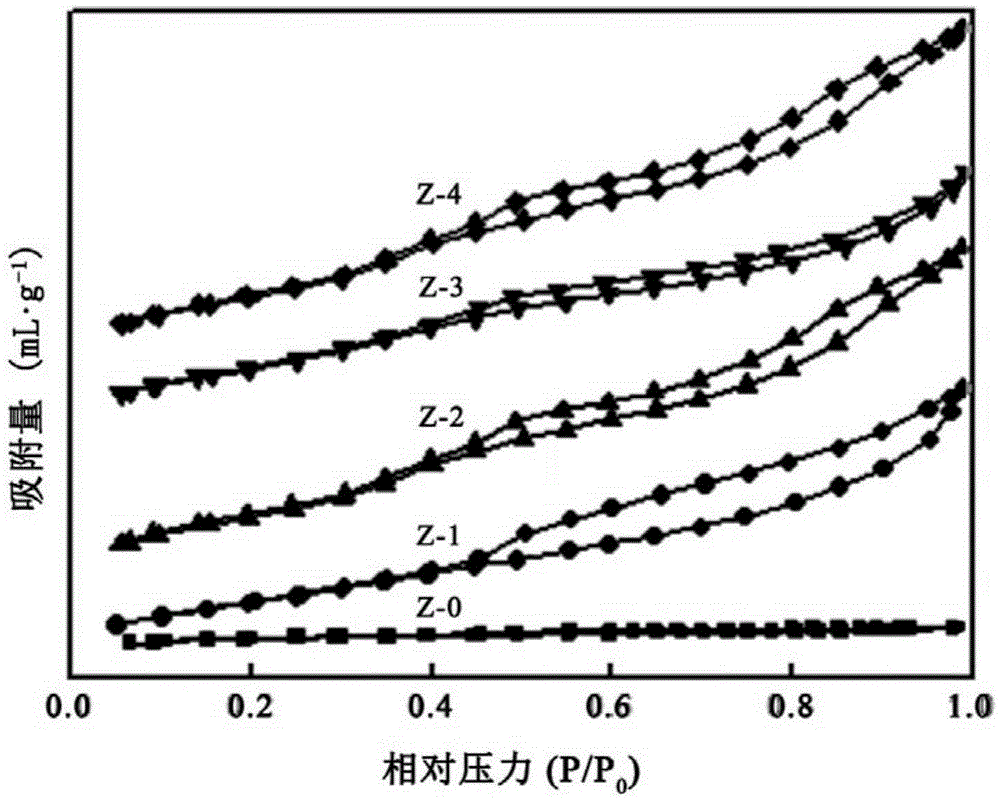

[0053] The powder XRD test result of the step hole ZSM-5 zeolite Z-2 that the present embodiment obtains is as follows figure 1 with figure 2 Shown, N 2 Adsorption-desorption isotherms such as image 3 As shown, the ammonia temperature-programmed desorption curve is as follows Figure 4 shown.

Embodiment 3

[0055] This embodiment provides a kind of stepped pore ZSM-5 zeolite, which is prepared through the following steps:

[0056] The preparation method is generally the same as that in Example 1, except that the template agent is replaced with 1.94 g of three-head cationic polyquaternium salt, and other conditions remain unchanged, and the prepared H-type stepped pore ZSM-5 zeolite is recorded as Z-3.

[0057] The powder XRD test result of the step hole ZSM-5 zeolite Z-3 that the present embodiment obtains is as follows figure 1 with figure 2 Shown, N 2 Adsorption-desorption isotherms such as image 3 As shown, the ammonia temperature-programmed desorption curve is as follows Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com