Molecular sieve modified catalyst, preparation method and application thereof to preparation of acrylic ester

A technology of acrylate and molecular sieve, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, and the preparation of organic compounds, etc., can solve problems such as no major breakthroughs, and achieve the effects of promoting reactivity, improving crystal structure, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

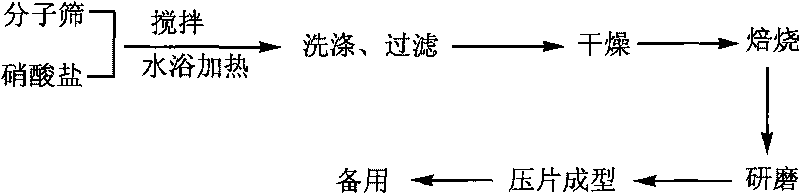

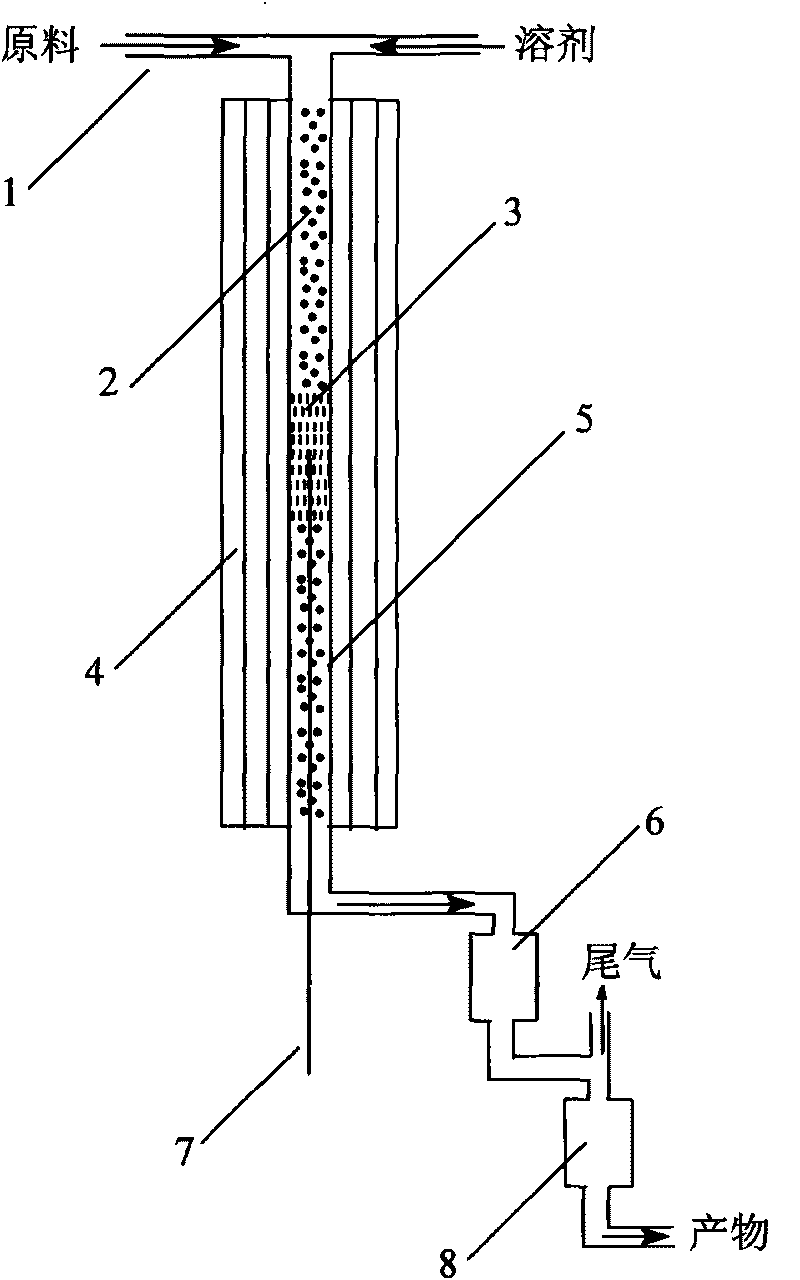

[0027] Step 1 weighs 20g of NaX (Si / Al=10), 0.82g Ca (NO 3 ) 2 , into a round bottom flask, dissolved in deionized water.

[0028] Step 2 Stir the material in step 1 for 6 hours at 80° C. in a water bath, and soak for 4 hours.

[0029] In step 3, the catalyst prepared in step 2 is suction-filtered and washed, and no nitrate ions are detected.

[0030]Step 4 Put the filter cake in step 3 in an oven to dry at 120°C until there is no free water, roast at 300°C for 4 hours, press into tablets, grind to get 18-35 mesh catalyst, put it in a desiccator for use.

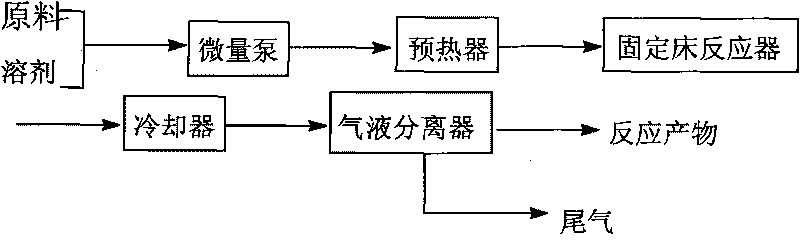

[0031] Step 5: Use the catalyst prepared in step 4 to prepare acrylic acid and its butyl ester by dehydrating butyl lactate. Specific reaction conditions: temperature 300°C, normal pressure, space velocity 1h -1 , n (methanol): n (butyl lactate)=0.5, experimental results: the conversion rate of butyl lactate reaches 92.1%, and the molar selectivity of acrylic acid and its butyl ester reaches 60.5%.

Embodiment 2

[0033] Step 1 weighs quantitative 20gNaX (Si / Al=15), 0.47gLa (NO 3 ) 3 , into a round bottom flask, dissolved in deionized water.

[0034] Steps 2-3: Same as Steps 2-3 in Example 1.

[0035] Step 4 Put the filter cake in step 3 in an oven to dry at 120°C until there is no free water, roast at 350°C for 4 hours, press into tablets, grind to get a 18-35 mesh catalyst, put it in a desiccator for use.

[0036] Step 5 The catalyst prepared in step 4 is used for the reaction of dehydrating butyl lactate to prepare acrylic acid and its butyl ester. The specific reaction conditions are: temperature 320°C, normal pressure, space velocity 1h -1 , n (methanol): n (butyl lactate)=0.5, experimental results: the conversion rate of butyl lactate reaches 93.2%, and the molar selectivity of acrylic acid and its butyl ester reaches 61.4%.

Embodiment 3

[0038] Step 1: Weigh quantitative 20gNaY (Si / Al=20), 1.04gKNO 3 , into a round bottom flask, dissolved in deionized water.

[0039] Steps 2-3: Same as Steps 2-3 in Example 1.

[0040] Step 4 Put the filter cake in step 3 in an oven to dry at 120°C until there is no free water, bake at 350°C for 5 hours, press into tablets, grind to get 18-35 mesh catalyst, put it in a desiccator for later use.

[0041] Step 5: The catalyst prepared in step 4 is used for the reaction of dehydrating butyl lactate to prepare acrylic acid and its butyl ester. Specific reaction conditions: temperature 340°C, normal pressure, space velocity 2h -1 , n (methanol): n (butyl lactate)=1, experimental results: the conversion rate of butyl lactate reaches 92.8%, and the molar selectivity of acrylic acid and its butyl ester reaches 63.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com