Water boiling-resistant high-color fastness polyester resin for TGIC powder coating and preparation method thereof

A powder coating and polyester resin technology, applied in powder coatings, polyester coatings, coatings, etc., can solve the problems of poor leveling, poor weather resistance, low acid value and viscosity, and achieve small color difference and excellent water boiling resistance. With mechanical properties, the effect of preventing fading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

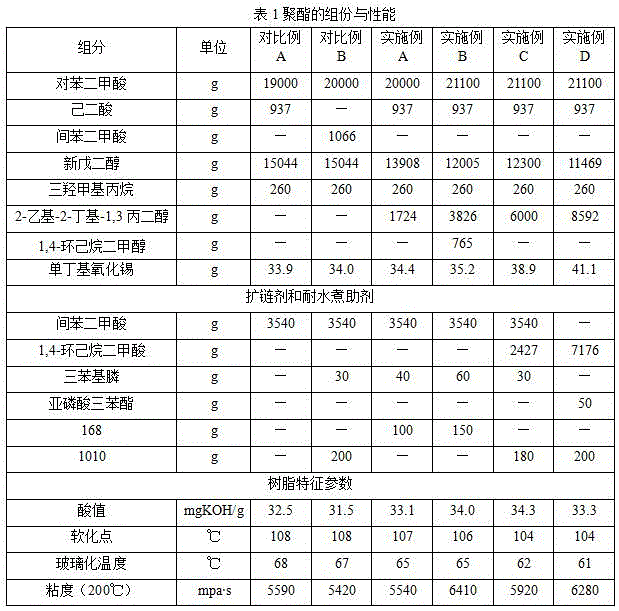

Image

Examples

Embodiment Construction

[0037] The following are specific embodiments of the present invention, the purpose of which is to help the understanding of the present invention rather than to limit the present invention.

[0038] (1) Take the polyol and heat it up until the material melts, then add the proportioned amount of polyacid and catalyst, and continue the temperature rise reaction with nitrogen gas, until 180°C esterification water begins to form and distill; then gradually raise the temperature to 250°C, and react 2 ~5 hours until 95% of the esterification water is discharged, the reaction system is clear and free of particles, and the acid value reaches 9~18mgKOH / g;

[0039] (2) Add the proportioned amount of chain extender into the reaction kettle and react for 3~5 hours. After the acid value reaches 35~55mgKOH / g, vacuumize and polycondense for 1~4 hours. The acid value reaches 25~45mgKOH / g, and the melt viscosity is 3000~8000mPa∙s (ICI cone-plate viscometer, 200°C), at this time, add boiling-r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com