Vacuum roller drying bin

A technology of vacuum drums and drying bins, applied in the direction of drying solid materials, drying chambers/containers, non-progressive dryers, etc., which can solve the problems of high production costs, complicated heat pipe production, and large thermal efficiency loss, etc., to improve the effective utilization rate , enhanced drying efficiency, increased cooling area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

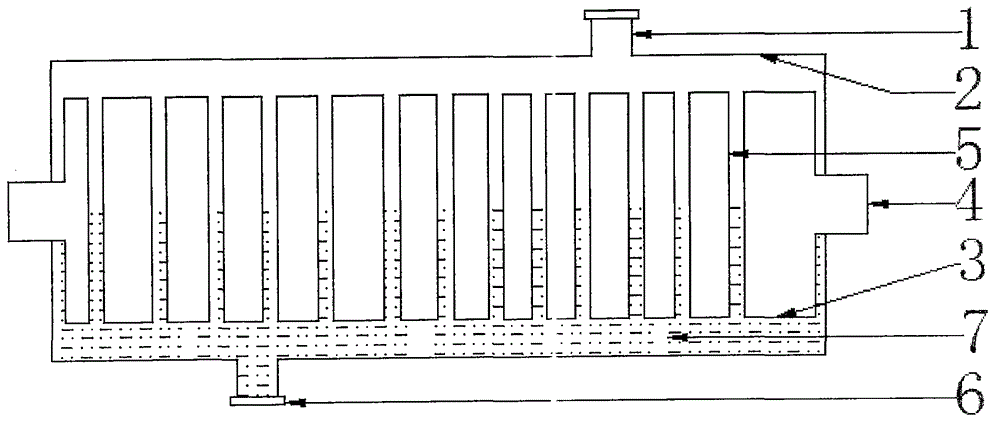

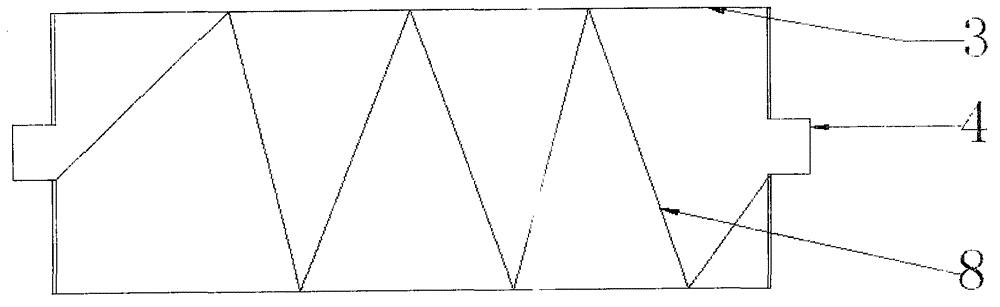

[0050] Such as figure 1 , figure 2 A vacuum drum drying chamber shown is composed of an outer shell (2) and an inner shell (3).

[0051] The exterior shape of the vacuum drum drying chamber is cylindrical.

[0052] 1. The diameter of the vacuum drum drying chamber is 1500mm.

[0053] 2. The length of the vacuum drum drying chamber is 6000mm.

[0054] The outer shell (2) and the inner shell (3) of the vacuum drum drying chamber are made of metal plates.

[0055] The outer shell (2) and the inner shell (3) are cylinders rolled and welded by metal plates.

[0056] 1. The thickness of the metal plate is 4mm.

[0057] 2. The metal plate is a metal composite plate.

[0058] The outer shell (2) is outside the inner shell (3), and the inner shell (3) is inside the outer shell (2).

[0059] 1. The inner cavity of the distance between the outer shell (2) and the inner shell (3) is closed and airtight.

[0060] 2. The distance between the outer shell (2) and the inner shell (3) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Tube spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com