A method for rapidly detecting the content of lead and cadmium in the coating of galvanized steel sheet

A galvanized steel plate and coating technology, which is applied in the field of inspection and testing, can solve the problems of large consumption of chemical reagents, quality errors of substrates, and lengthy analysis cycles, etc., and achieve the effects of reducing test steps, fast analysis speed, and low detection limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

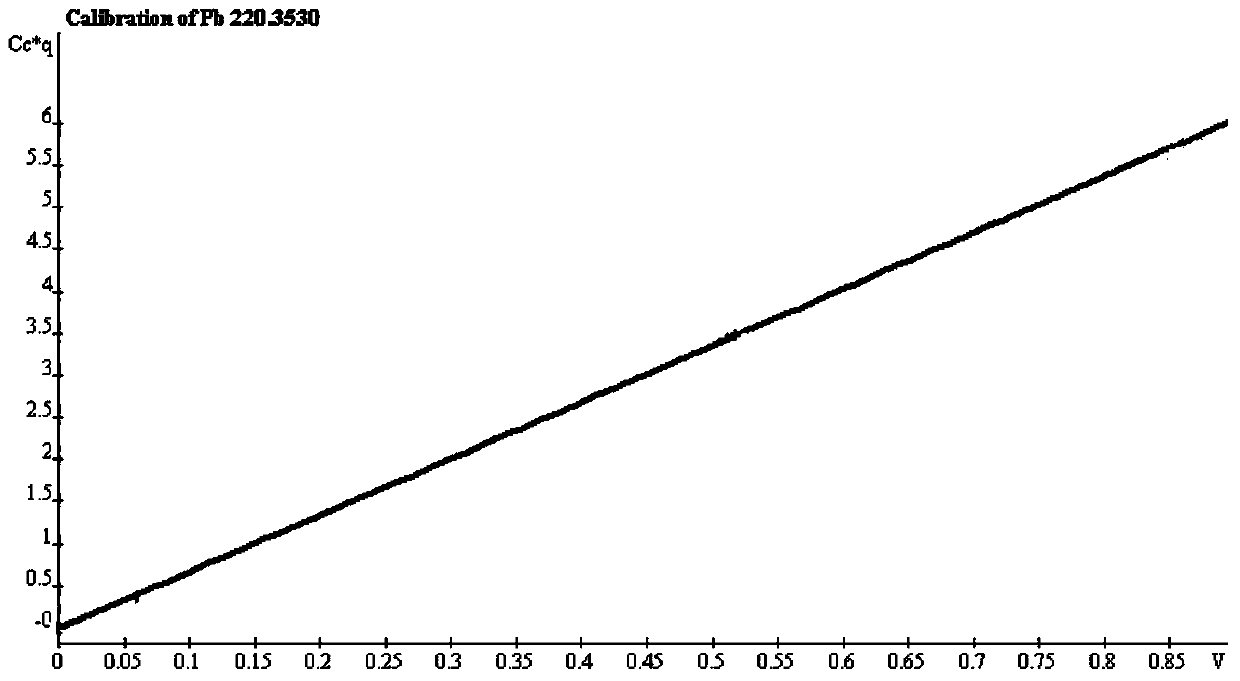

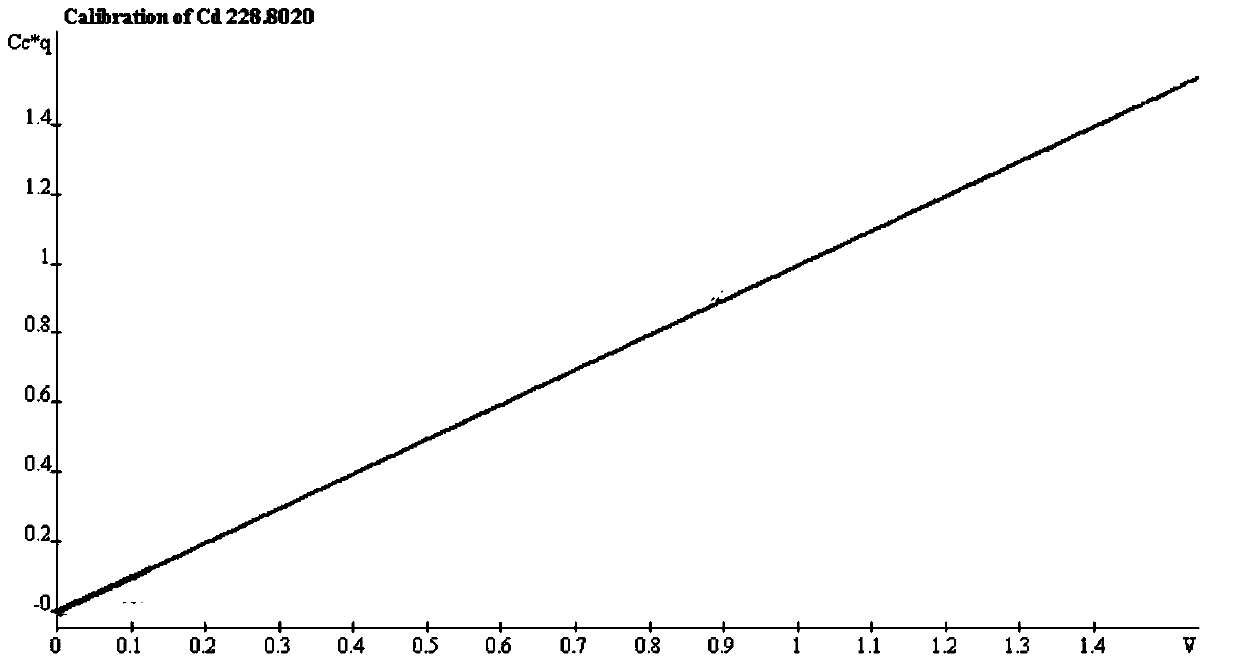

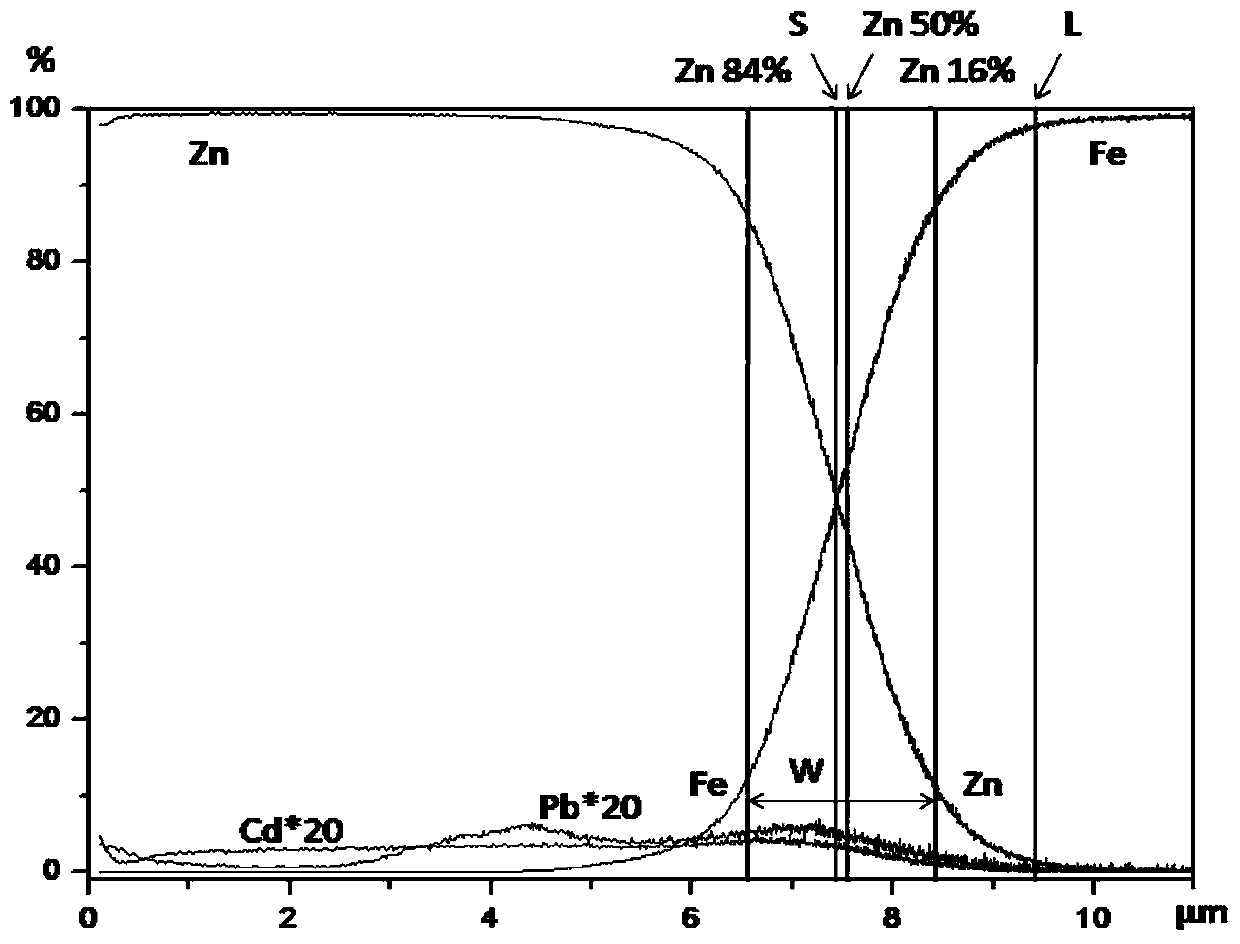

[0089] Select five typical galvanized steel sheets to test the Pb and Cd elements in the coating. The quantitative analysis diagram of the coating depth of the selected galvanized steel sheets is shown in Figure 8 ~ Figure 12 .

[0090] The contents of Pb and Cd elements in the selected galvanized steel coating are shown in Table 4:

[0091] Table 4 Mass fractions of Pb and Cd elements in typical galvanized steel coatings (ppm)

[0092]

Embodiment 2

[0094] This example is the verification of the detection limit of the method of the present invention.

[0095] Using the established method, the pure zinc sample RZn 11 / 1 was used as the test sample, and the continuous measurement was carried out 11 times. The three times standard deviation of the result was the detection limit of each element of the method. The results are shown in Table 5.

[0096] The results of the Pb and Cd detection limits of the method in Table 5

[0097]

Embodiment 3

[0099] This example is a short-term stability verification of the method of the present invention.

[0100] The standard sample RZn 12 / 15 was used to measure the short-term stability, and the sample RZn 12 / 15 was excited 15 times, and the average value and standard deviation of the results were calculated. The results are shown in Table 6. The relative standard deviation values of Pb and Cd elements are all less than 10%, and the short-term stability results of the elements meet the requirements.

[0101] Table 6 Short-term stability results

[0102]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com