A kind of SRU fault confirmation method and device based on detection heat platform

A fault and signal technology, applied in the field of SRU fault confirmation based on the detection hot stage, which can solve problems such as large uncertain factors, difficult SRU testing, and difficulty in fault confirmation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

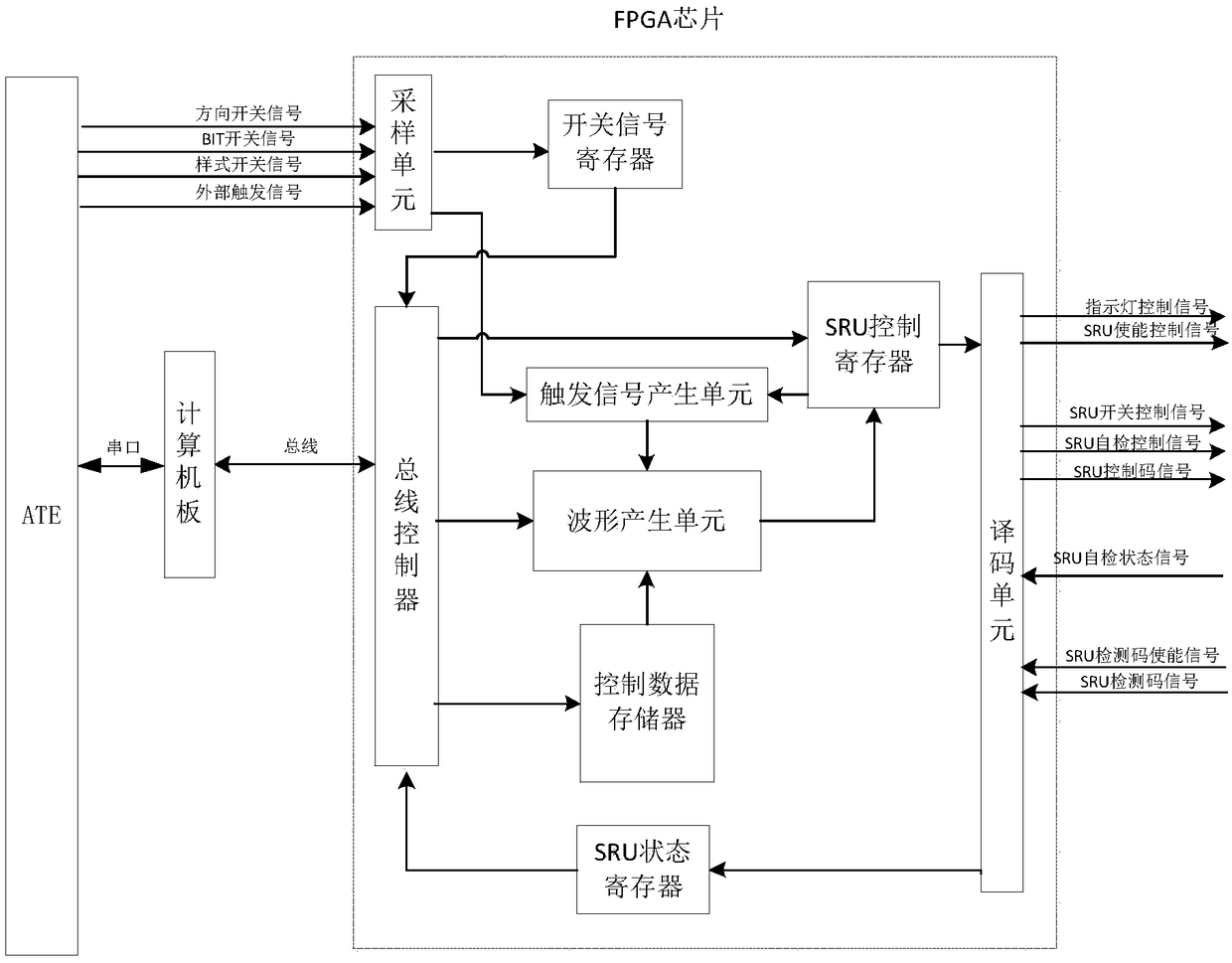

[0063] A kind of SRU failure confirmation method based on detection hot platform, SRU self-inspection function test comprises:

[0064] Step 1: Insert the SRU whose fault needs to be confirmed into the detection hot station;

[0065] Step 2: ATE sends the corresponding command 7e 0D 0B 01... 00 00 00 7e through the serial port;

[0066] Step 3: The computer board receives and analyzes the serial port command sent by ATE, and sends it to the bus controller;

[0067] Step 4: The sampling circuit collects the inherent basic signal sent by ATE, and sends it to the switch signal register for storage;

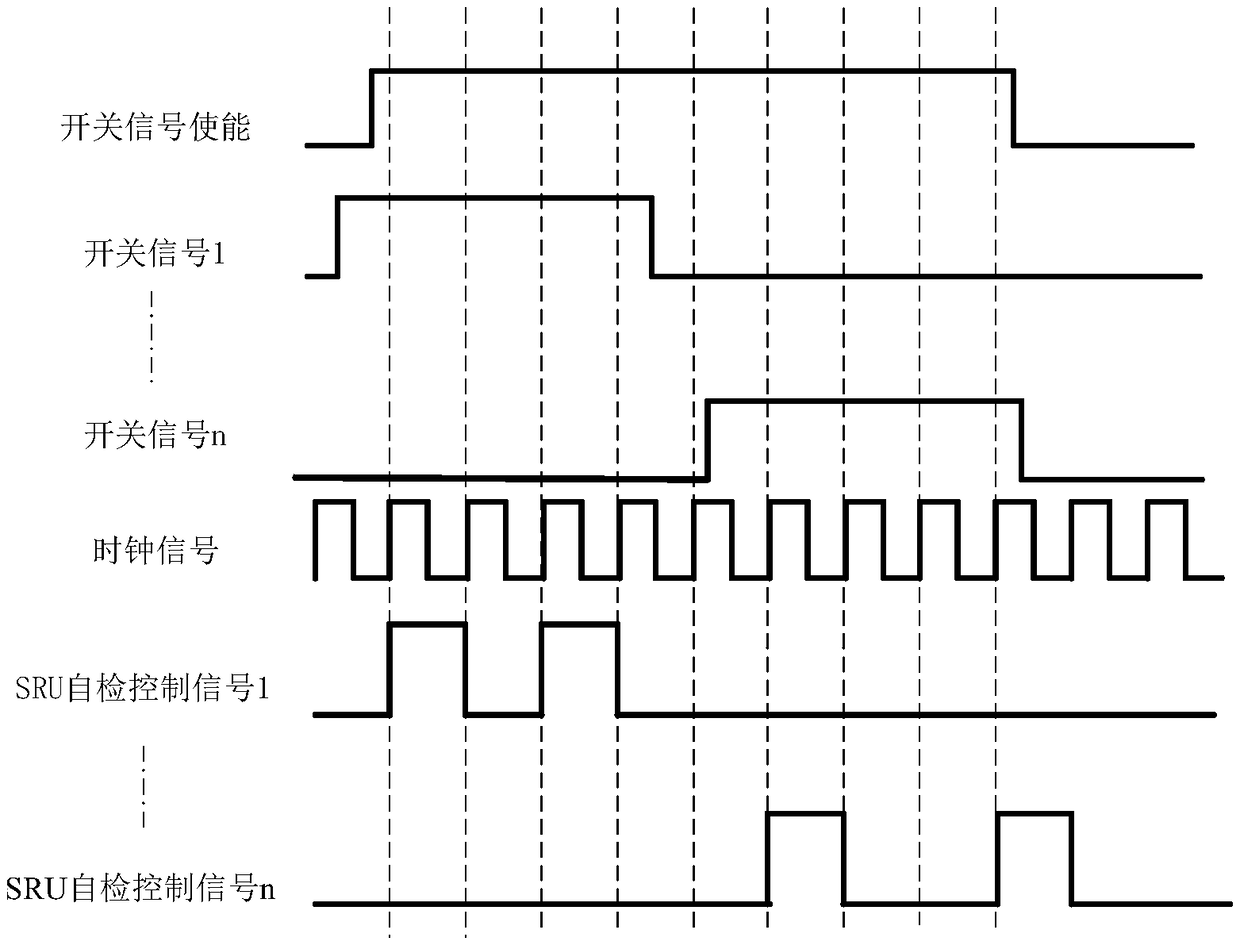

[0068] Step 5: The bus controller reads the BIT switch signal and direction switch signal in the switch signal register according to the instructions of the computer board, and at the same time generates the address decoding enable control signal and indicator light control of the SRU module according to the operation of the computer board on the external storage space The signal i...

Embodiment 2

[0073] Embodiment two: a kind of SRU failure confirming method based on detecting hot platform, SRU functional performance test is characterized in that comprising:

[0074] Step 1: Insert the SRU whose fault needs to be confirmed into the detection hot station;

[0075] Step 2: ATE sends the test command 7e 0D 0B 02... 00 00 00 7e through the serial port;

[0076] Step 3: The computer board receives and analyzes the serial port command sent by ATE, and sends it to the bus controller;

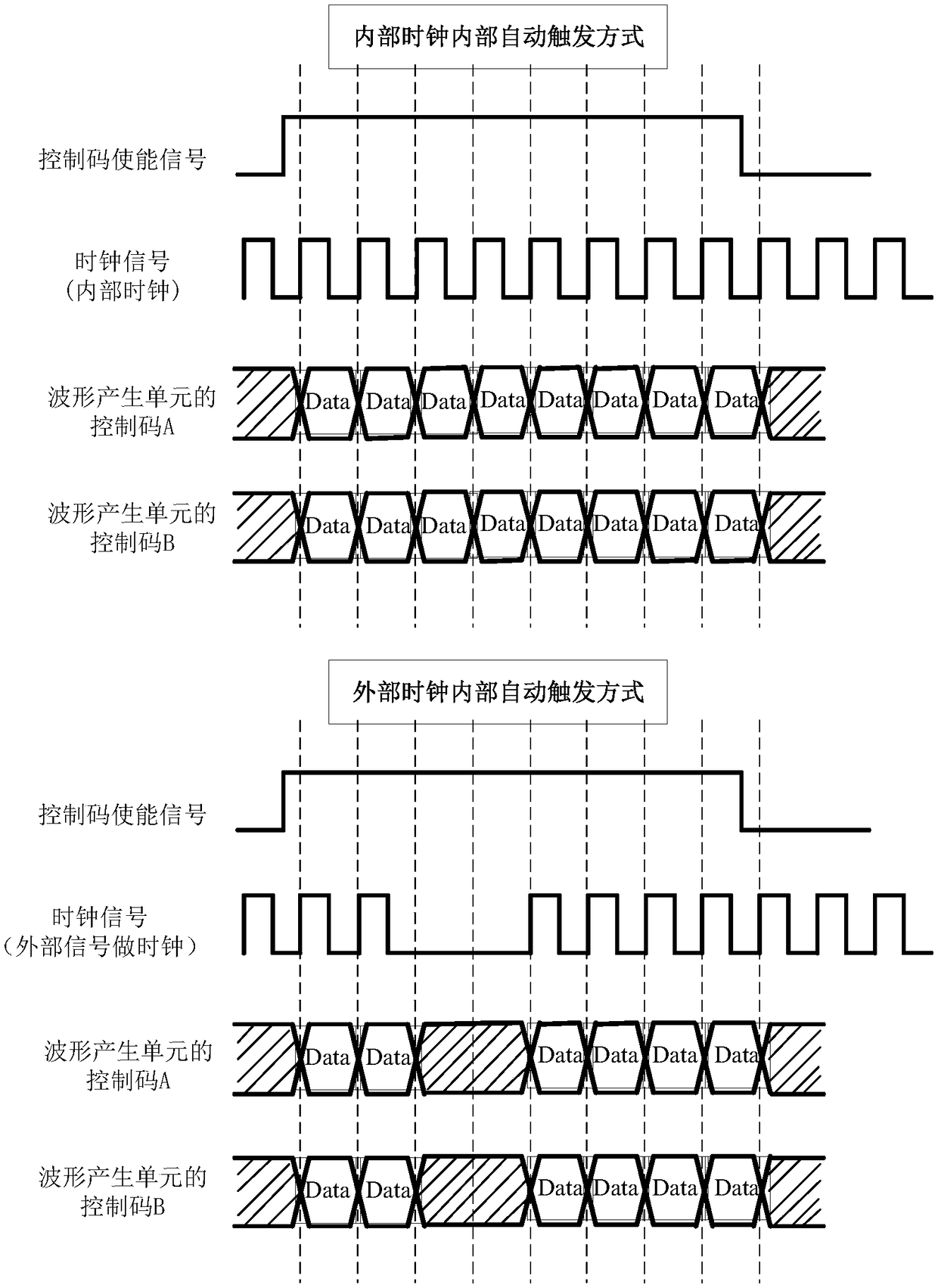

[0077] Step 4: The sampling circuit collects the inherent basic signal sent by ATE, sends it to the switch signal register for storage, and sends it to the trigger signal generating unit for external triggering to generate the waveform signal required for SRU testing;

[0078] Step 5: The bus controller generates the enable signal and control signal of the SRU module to the SRU control register according to the operation of the computer board on the external storage space, and at the same time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com