A method of preparing a freeze-drying excipient by using rolling dies and a product thereof

A freeze-dried excipient and roll-molding technology, which is applied in the field of freeze-dried excipient preparations, can solve the problems of single shape, single form, and difficult multi-layer structure of the preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

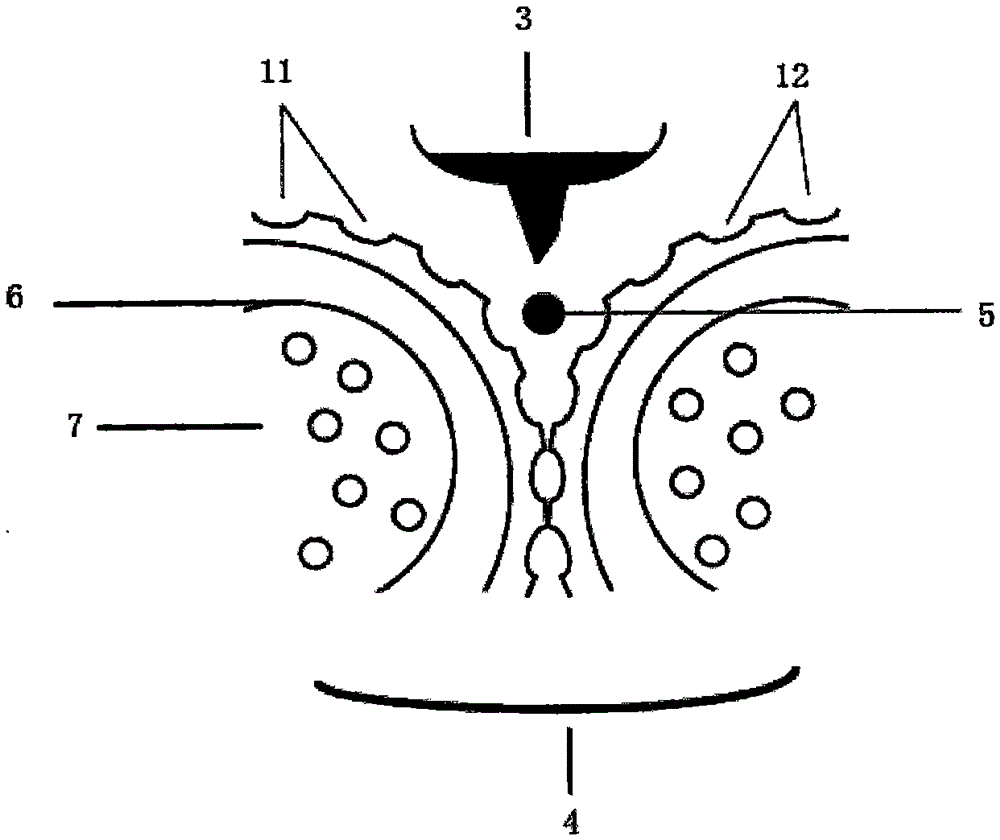

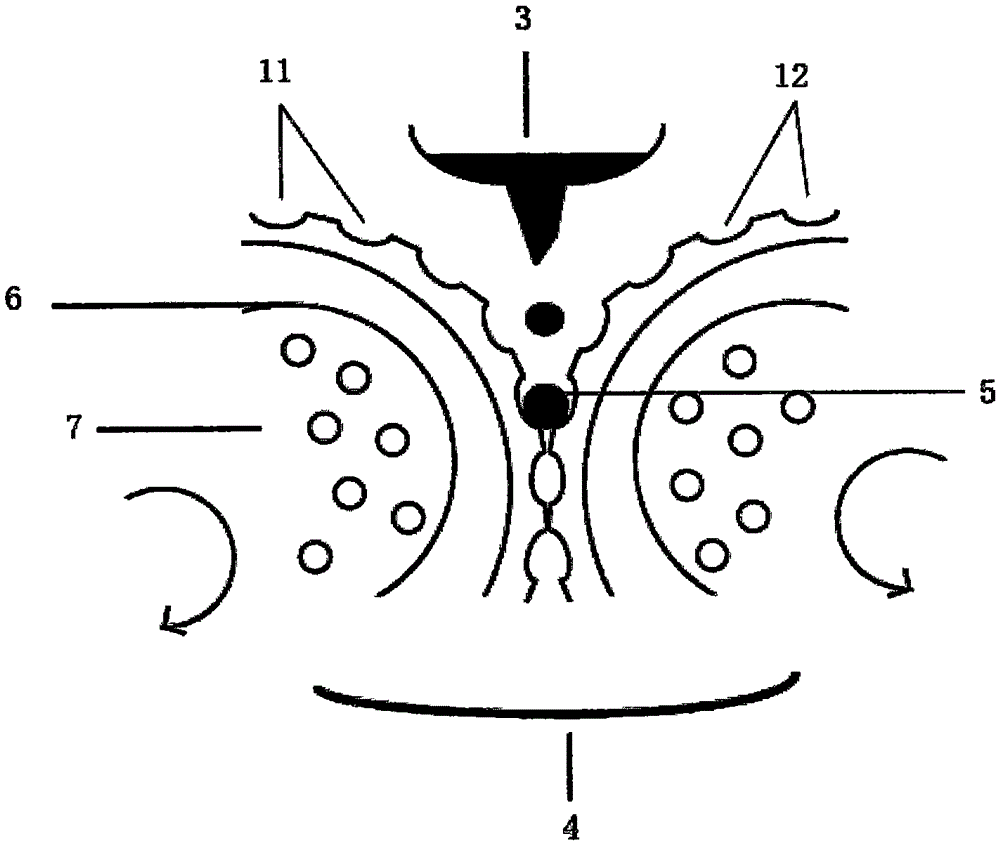

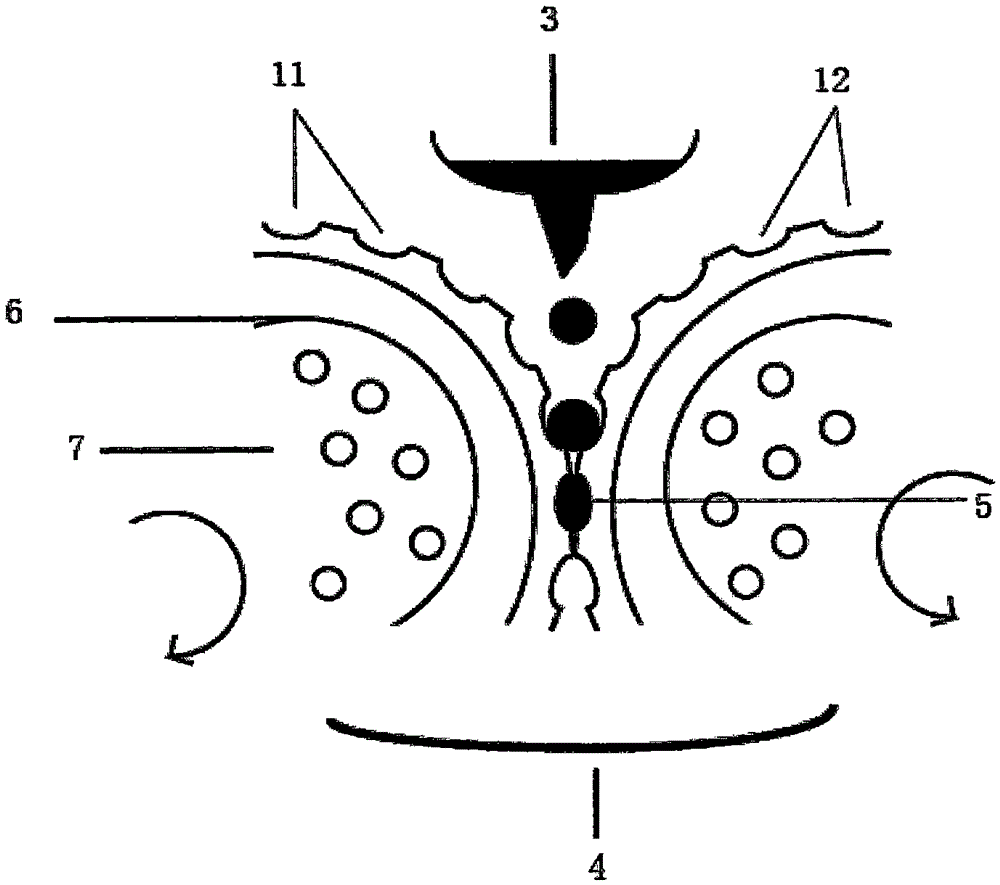

[0074] A. Use a relatively rotating rolling mold combination, including rolling mold (1), rolling mold (2), filling head (3), and material tray (4); among them, rolling mold (1) and rolling mold (2) The surface has a concave mold (11) and a concave mold (12) of a certain shape, the shape of which is hemispherical, and when the concave mold (11) and the concave mold (12) are docked, a complete spherical shape can be formed with a gap of 1 mm;

[0075] B. The rolling mold (1) and the rolling mold (2) are precooled by injecting liquid nitrogen (7) into the hollow pipe (6) therein, and the temperature of the rolling film after precooling is -20°C;

[0076] C, bilberry extract: pullulan=5:1, add water to prepare a solution, centrifuge and degas to obtain the stock solution of freeze-dried excipient preparation;

[0077] D, the roller molds (1) and (2) are rotated, when the concave mold (11) on its surface and the lower edge of the concave mold (12) are engaged, the freeze-dried exc...

Embodiment 2

[0082] A. Use a relatively rotating rolling mold combination, including rolling mold (1), rolling mold (2), filling head (3), and material tray (4); among them, rolling mold (1) and rolling mold (2) The surface has a concave mold (11) and a concave mold (12) of a certain shape, each of which is capsule-shaped, and when the concave mold (11) and the concave mold (12) are docked, a complete capsule shape can be formed, with a gap of 0.5 mm;

[0083] B, precooling the rolling mold (1) and the rolling mold (2), the precooling temperature is 0°C;

[0084] C. Mix GTCC: vitamin D: lecithin = 5:1:1 fully, vacuum degassed to prepare component 1; hydrolyzed gelatin: pullulan = 1:1, add water to fully stir, centrifuge and degas to prepare component two;

[0085] D. The roller molds (1) and (2) are rotated, and when the concave mold (11) on the surface and the lower edge of the concave mold (12) are joined, component one and component two are filled into the concave mold (11) in sequence...

Embodiment 3

[0090] A. Use a relatively rotating rolling mold combination, including rolling mold (1), rolling mold (2), filling head (3), and material tray (4); among them, rolling mold (1) and rolling mold (2) The surface has a concave mold (11) and a concave mold (12) of a certain shape, and its overall shape is mango-shaped, and the respective shapes of the concave mold (11) and the concave mold (12) are asymmetrical, and a complete mango shape can be formed when they are docked. Gap 0.3mm;

[0091] B, precooling the rolling mold (1) and the rolling mold (2), the precooling temperature is -10°C;

[0092] C. Concentrated mango juice: trehalose = 3: 1, add water to prepare a solution, centrifuge and degas to obtain the stock solution of freeze-dried excipient preparation;

[0093] D, the roller molds (1) and (2) are rotated, when the concave mold (11) on its surface and the lower edge of the concave mold (12) are engaged, the freeze-dried excipient preparation stock solution (5) is fill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com