Thorium and uranium separating and recovering method

A technology of separation and recovery, acid aqueous solution, applied in the field of separation and recovery of thorium and uranium, and can solve the problems of low thorium yield and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

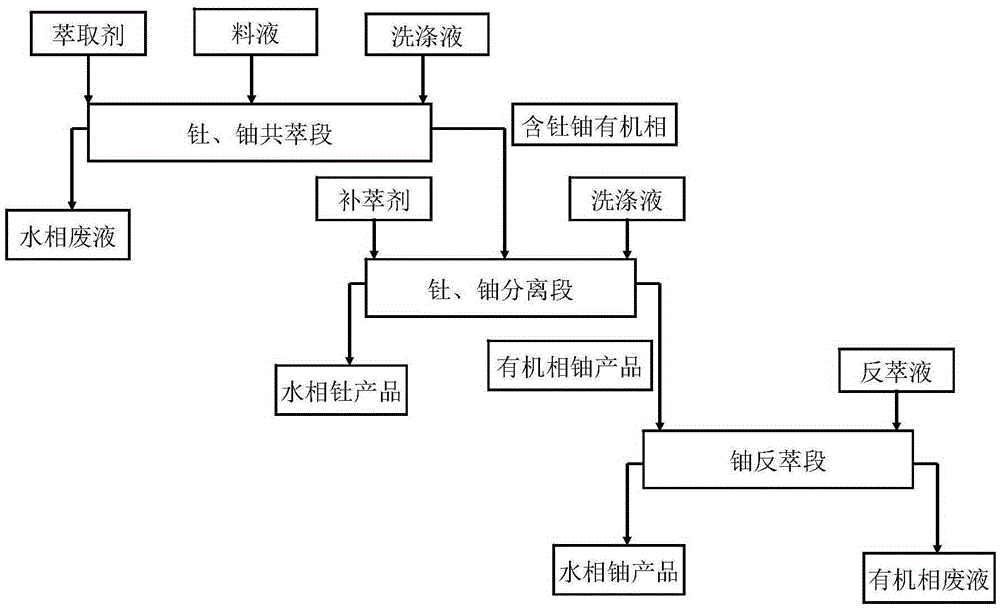

Method used

Image

Examples

Embodiment 1

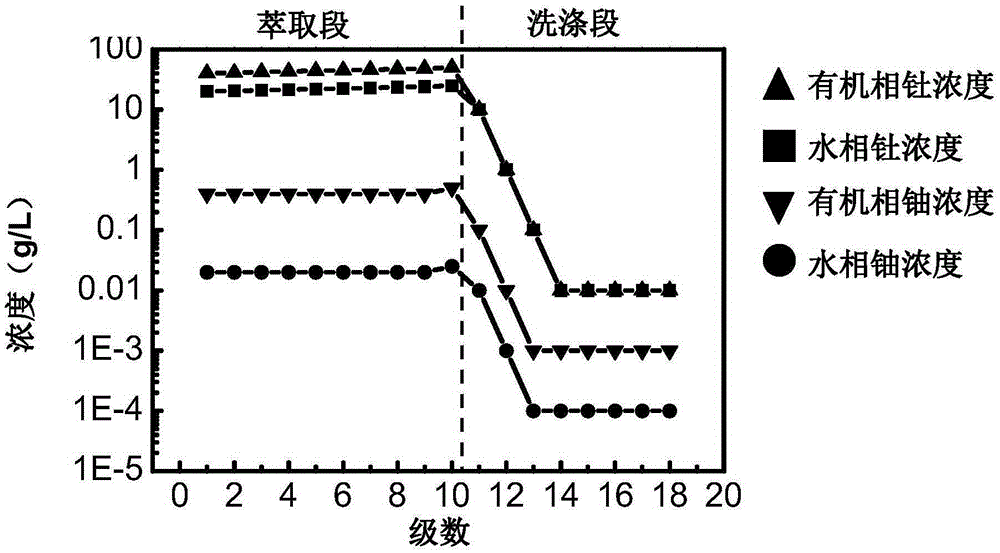

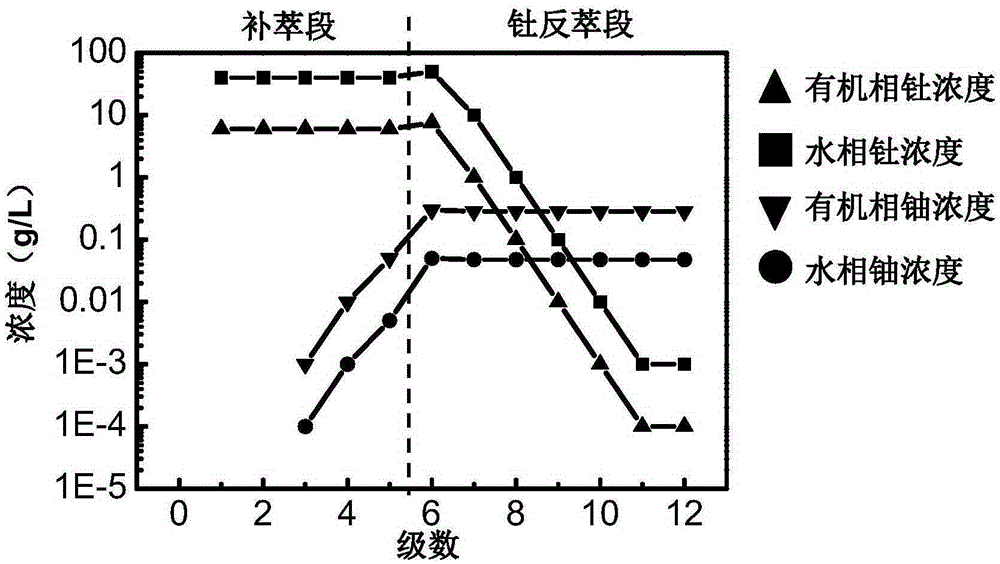

[0032] 1) Using kerosene as an organic solvent, prepare an organic solution with a volume concentration of 25% of methylphosphonic acid bis(1-methyl)heptyl, as an extractant, prepare a Th 4+ , UO 2 2+ 、Zr 4+ , Nb 5+ , Ru(RuNO 3+ ), Rh 3+ 、Sr 2+ 、Cs + 、Ce 3+ 、Ce 4+ 、Gd 3+ 、Dy 3+ 1M aqueous nitric acid solution, where Th 4+ , UO 2 2+The concentration is 200g / L, 2g / L, and the concentration of other metal ions is 20ppm. As the feed liquid, a 0.2M aqueous solution of nitric acid is prepared, and as the washing liquid, the above solution is subjected to fractional extraction. The extraction stages are 10, and the washing stages are Level 8, the flow ratio of feed liquid, extractant, and washing liquid is 1:5:0.5, thorium and uranium are extracted into the organic phase, while impurity metal ions remain in the water phase, the concentration of thorium and uranium in the organic phase and water phase at all levels distributed as figure 2 shown;

[0033] figure 2 The...

Embodiment 2

[0039] 1) Using n-dodecane as an organic solvent, prepare an organic solution with a volume concentration of 15% of methylphosphonic acid bis(1-methyl)heptyl, as an extractant, prepare a Th 4+ , UO 2 2+ 、Zr 4+ , Nb 5+ , Ru(RuNO 3+ ), Rh 3+ 、Sr 2+ 、Cs + 、Ce 3+ 、Ce 4+ 、Gd 3+ 、Dy 3+ 2M aqueous nitric acid solution, where Th 4+ , UO 2 2+ The concentration is 200g / L, 2g / L, and the concentration of other metal ions is 20ppm. As the feed liquid, a 0.2M aqueous solution of nitric acid is prepared, and as the washing liquid, the extraction agent, feed liquid and washing liquid are subjected to fractional distillation extraction, and the number of extraction stages is 10. Level, the number of washing stages is 6, the flow ratio of feed liquid, extractant, and washing liquid is 1:7:1, thorium and uranium are extracted into the organic phase, while impurity metal ions remain in the water phase;

[0040] 2) Using kerosene as an organic solvent, prepare an organic solution wit...

Embodiment 3

[0044] 1) Using n-dodecane as an organic solvent, prepare an organic solution with a volume concentration of 20% of methylphosphonic acid bis(1-methyl)heptyl, as an extractant, prepare a Th 4+ , UO 2 2+ 、Zr 4+ , Nb 5+ , Ru(RuNO 3+ ), Rh 3+ 、Sr 2+ 、Cs + 、Ce 3+ 、Ce 4+ Gd 3+ 、Dy 3+ 0.6M aqueous nitric acid solution, where Th 4+ , UO 2 2+ The concentration is 200g / L, 2g / L, and the concentration of other metal ions is 20ppm. As the feed liquid, a 1.0M aqueous solution of nitric acid is prepared, and as the washing liquid, the extraction agent, feed liquid and washing liquid are subjected to fractional distillation and extraction, and the number of extraction stages is 9. level, the number of washing stages is 7, the flow ratio of feed liquid, extractant, and washing liquid is 1:4:0.8, thorium and uranium are extracted into the organic phase, while impurity metal ions remain in the water phase;

[0045] 2) Using kerosene as an organic solvent, prepare an organic soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com