Design method for large-dimension annular cone type ultrasonic amplitude transformer

A technology of ultrasonic horn and design method, which is applied in the direction of design optimization/simulation, calculation, fluid utilizing vibration, etc., and can solve the problems that the horn lacks a ring-shaped ultrasonic horn mathematical model and has no theoretical system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

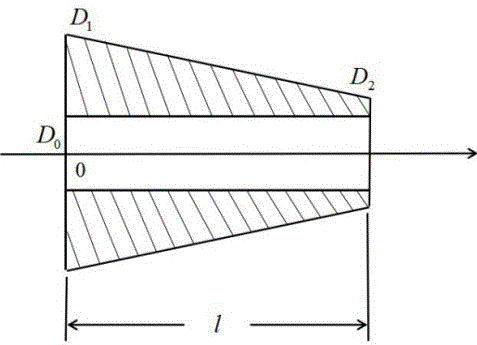

[0027] Specific implementation method: see attached figure 1 , the design method of a large-size annular conical ultrasonic horn, it is realized according to the following steps:

[0028] Step 1. The bus bar of the horn is selected as conical, and the vibration frequency is f, the longitudinal wave velocity is C, and the diameter of the large end is D 1 , the small end diameter is D 2 , the center hole diameter is D 0 , since the circular conical horn can be compared to the solid conical horn, so α, circular wave number k, and area coefficient N can be obtained as follows:

[0029]

[0030] in the known D 1 、D 2 、D 0 , f, C, you can find α, k, N and l.

[0031] The longitudinal wavelength λ is:

[0032]

[0033] When f and C are known, λ can be calculated.

[0034] Step 2. Substituting λ, k, and l obtained in step 1 into the resonance length formula (3) can obtain the resonance length L:

[0035]

[0036] Step 3. Substituting the k and α obtained in step 1 in...

Embodiment

[0044] The specific implementation will be further described below in conjunction with the examples, referring to the appended figure 1 , given D 1 =96mm,D 2 = 40mm, D 0 = 20mm, f = 20kHz, the material is No. 45 steel, then C = 5176376mm / s, get α = 0.00497, k = 0.0243, N = 3.8, l = 148.32mm, λ = 258.82mm.

[0045] Substitute the obtained λ, k, and l into the resonance length formula (3), and obtain the resonance length L=148.32mm.

[0046] Substitute the obtained k and α into the displacement node formula (4) to obtain the displacement node x 0 = 56.4 mm.

[0047] Substitute the obtained N, k and l into the amplification factor formula (5) to obtain the amplification factor M p = 3.74.

[0048] According to the obtained N, α, k and l, the shape factor can be obtained according to the formula (6)

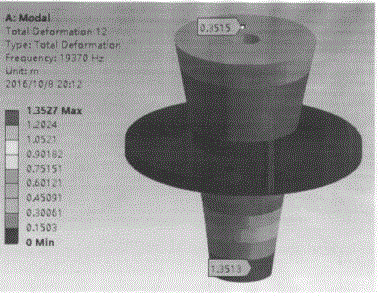

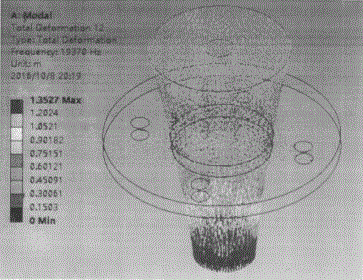

[0049] Use the simulation software to carry out numerical simulation based on the above given data and obtained results. The simulation results are shown in the attached f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com