Explosion method for tundra of high-and-cold surface mine

A permafrost, open-air technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

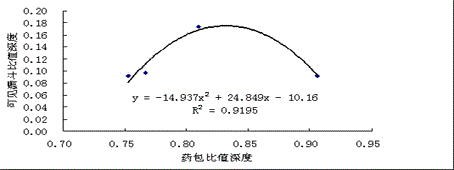

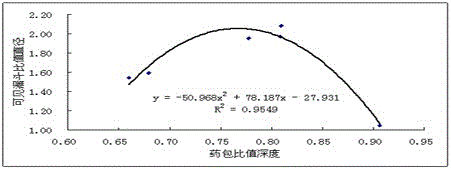

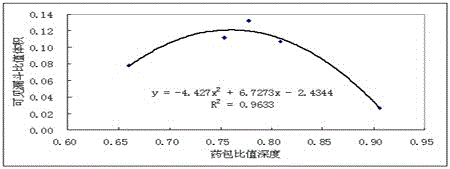

[0092] Example 1: Drilling using CM351 down-the-hole drilling rig with a diameter of 150mm. The detonating equipment adopts Yipuli on-site mixed explosives and Aurikai high-precision nonel detonator detonator to carry out funnel blasting. According to the diameter, depth and volume of the funnel According to the analysis of the weight and buried depth of the cartridge, the optimum ratio depth determined by the visible funnel is 0.76-0.82, with a change rate of 7%; the optimum ratio depth determined by the actual funnel is 0.79-0.81, with a change rate of 2 %, the test results determined that the best drug pack ratio depth was 0.78-0.80.

Embodiment 2

[0093] Example 2: When the thickness of the permafrost layer is 0.5-1m, the row spacing of the holes is not changed, the plugging height is reduced, and the height of the powder column is increased. See Table 5 and Table 6 for the hole network parameter design of the main blast hole in the permafrost region, and see Figure 7 . See the structure diagram of the blasthole charge Figure 8 , Figure 9 , Figure 10 , Figure 11 .

[0094] Table 5 Design of step parameters of Φ140mm Creeper CM351 drilling rig

[0095] project unit normal parameter Adjust parameter one Adjust parameter two stair height m 15 15 15 Drilling angle Spend 90 90 90 Hole diameter mm 140 140 140 Drilling depth m 16.5 16.5 16.5 Hole pitch×row pitch m 2

6×4.5 6×4.5 6×4.5 Charge length m 10.5 11 13 interval length m 2 2 0 plug length m 4 3.5 3.5 single hole charge kg 210 220 260 Single hole blasti...

Embodiment 3

[0098] Example 3: When the thickness of the permafrost layer is 1-2m, the auxiliary hole is perforated with a Φ140mm CM351 drilling rig, and the hole network parameters of the main blast hole and the charge structure are normal parameters. Example 2, the depth of the auxiliary hole: H=(2.0~ 4.0m ), the hole depth is mainly related to the thickness of frozen soil, see Figure 13 ;Drilling diameter: d = 140 / 150mm, take the best charge ratio depth of 0.80 m / kg 1 / 3 , See 12 for hole layout and wiring diagram.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com