Device and method for automatically grinding and re-burning scales in magnesium oxide vertical kiln

A shaft kiln and automatic technology, which is applied in the field of devices for automatically crushing and re-burning the weight in the magnesia shaft kiln, can solve the problems of the hanging furnace and the like, and achieve the effects of improving production efficiency, low operating cost and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

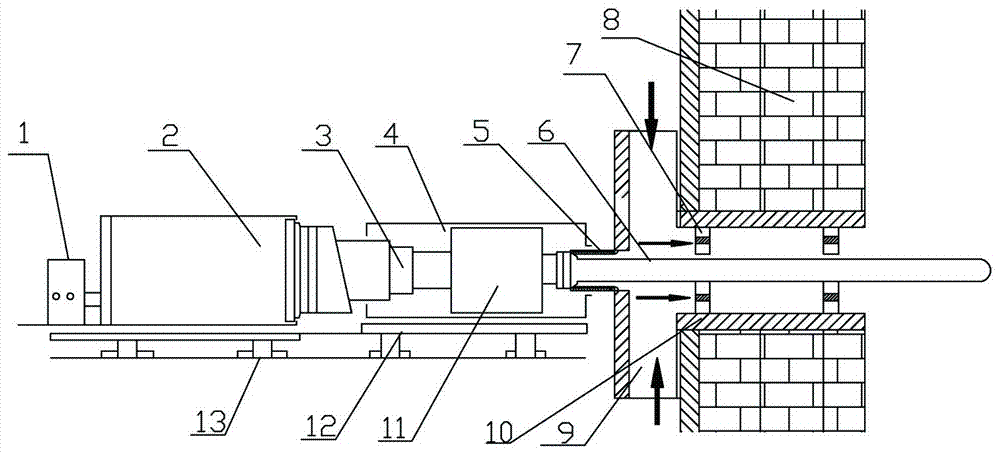

[0021] like figure 1 As shown, the present invention is a device for automatically crushing sintered magnesia shaft kiln lumps, comprising a shaft kiln body, a secondary air inlet 10 arranged at the lower part of the shaft kiln body, and a secondary The air duct 9 is arranged on the shaft kiln working platform 13 at the lower part of the secondary air duct, and is characterized in that a drive system 1 composed of a motor and a reducer and a hydraulic propulsion system connected with the drive system 1 are installed on the shaft kiln work platform 13 2 and the pneumatic crushing system 4 connected with the hydraulic propulsion system 2, the drive system 1 is mainly used to drive the hydraulic propulsion system and the pneumatic crushing device according to the set program; the hydraulic propulsion system 2 is composed of a high-pressure oil pump, an oil cylinder, a piston ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com