Artificial temporomandibular joint based on three-dimensional printing

A temporomandibular joint and three-dimensional printing technology, applied in 3D printing, joint implants, joint implants, etc., to achieve the effect of reducing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

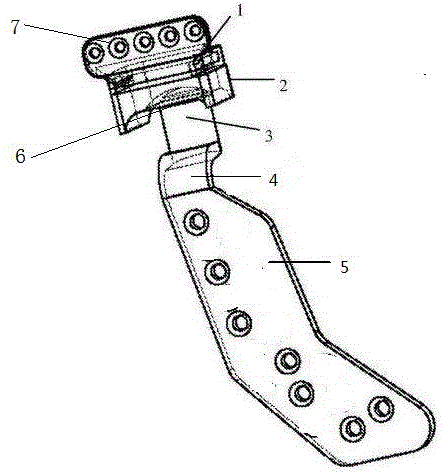

[0017] like figure 1 As shown, a kind of artificial temporomandibular joint based on three-dimensional printing of the best embodiment of the present invention includes temporomandibular articular process 1, temporal bone articular surface 6, condylar process 4 and condylar process fixation handle 5, and said temporomandibular articular surface 1. The temporal bone zygomatic process fixation piece forms the glenoid fossa, the top of the condyle 4 is the articular head 3, which is movably connected through the glenoid fossa 2, and the tail end of the condyle 4 is also provided with the condyle The condylar process fixation handle 5, the condyle process 4, the condyle process fixation handle 5, and the glenoid fossa are produced using three-dimensional printing technology. The material of the articular fossa will be three-dimensionally printed using polyetheretherketone and other materials with high wear resistance and good biocompatibility, which can reduce the wear and tear of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com