Preparation method for carbon aerogel composite material

A technology of carbon airgel and composite materials, applied in the field of composite materials, can solve the problems of complex preparation process and poor controllability of electrical conductivity, etc., achieve good hydrophilicity, reduce electrode internal resistance, and save process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

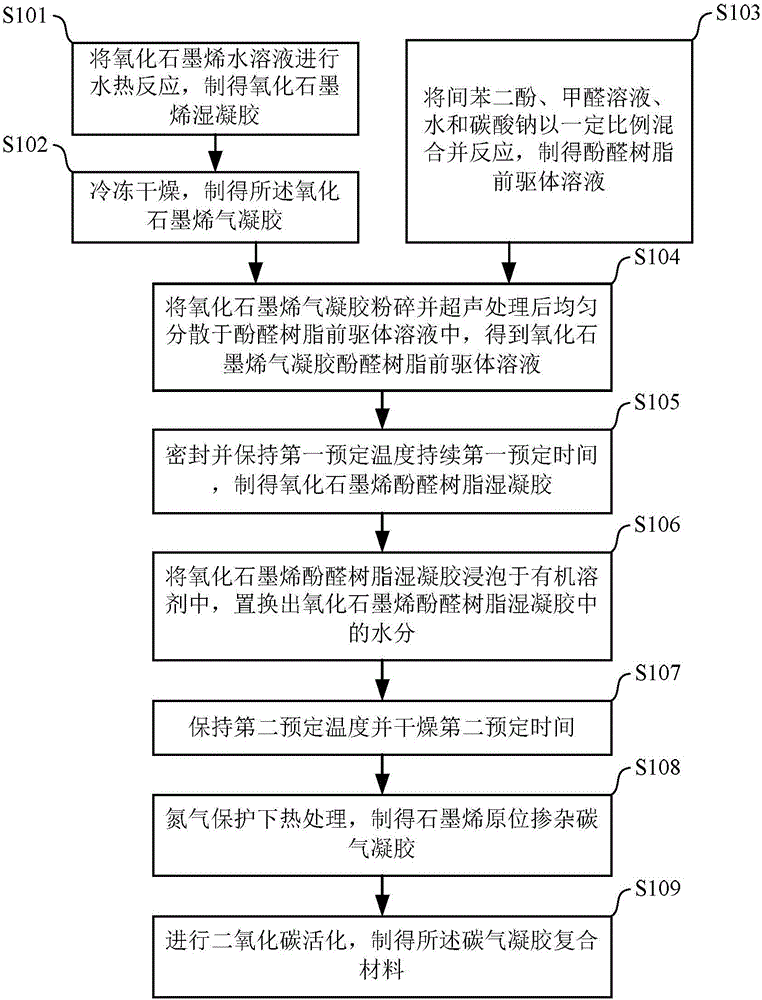

[0020] The invention provides a method for preparing a carbon airgel composite material. In the preparation method of the carbon airgel composite material, the prepared graphene oxide airgel is pulverized and ultrasonically treated and uniformly dispersed in a phenolic resin precursor solution. The graphene oxide airgel phenolic resin precursor solution is obtained, and the graphene oxide airgel phenolic resin precursor solution is sealed and kept at a constant temperature for a period of time to prepare a graphene oxide phenolic resin wet gel. Next, the moisture in the graphene oxide phenolic resin wet gel is replaced and dried to prepare the graphene oxide phenolic resin airgel. Heat treatment of the graphene oxide phenolic resin airgel, so that the reduction of the graphene oxide airgel in the graphene oxide phenolic resin airgel and the carbonization of the phenolic resin airgel are carried out simultaneously, and the in-situ doped carbon of graphene is obtained. airgel. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com