Low temperature forming preparation method for getter

A getter, low-temperature technology, applied in the field of low-temperature molding and preparation of getters, can solve the problems of reducing the getter performance of the getter element, the influence of the activity of the getter powder, etc., to improve the dimensional accuracy and product consistency, reduce the Poisoning effect, activity-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

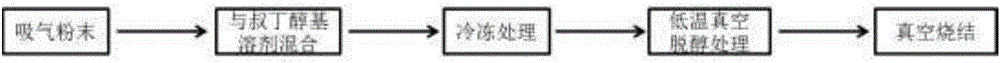

[0021] Such as figure 1 As shown, the Zr-V-Fe alloy (wherein the mass fraction of each component is Zr: 70%, V: 24.6%, Fe: 5.6%) and tert-butanol-based solvent (wherein the mass percentage of tert-butanol is 85%, The mass percentage of the binder is 15%) and is configured as an air-absorbing powder slurry, wherein the mass percentage of the Zr-V-Fe alloy powder is 81.5%. The slurry was poured into the mold, and then placed in a high and low temperature oven at -10°C for 20 minutes. After the green body of the getter element is formed, it is put into a vacuum box at a temperature of -10° C. for dealcoholization. The vacuum degree of the vacuum box is 100 Pa and kept for 10 hours. Put the dealcoholized getter element green body into the vacuum sintering furnace, and evacuate to 10 -3 Pa, heat up to 1000°C for sintering. Compared with the getter element with this composition ratio prepared by the traditional process, the suction rate and the suction volume are respectively inc...

Embodiment 2

[0023] Such as figure 1 As shown, Ti powder and Mo powder are mixed according to the mass ratio of 90:10 and tert-butanol-based solvent (wherein the mass percentage of tert-butanol is 90%, and the mass percentage of binder is 10%) to form an air-absorbing powder slurry, Wherein the mass percent of Ti and Mo mixed powder is 75%. The slurry is poured into the mold, and then placed in a high and low temperature oven at -20°C for 25 minutes. After the green body of the getter element is formed, it is put into a vacuum box at a temperature of -10°C for dealcoholization treatment, and the vacuum degree of the vacuum box is 10 Pa and kept for 12 hours. Put the dealcoholized getter element green body into the vacuum sintering furnace, and evacuate to 10 -4 Pa, heat up to 890°C for sintering. Compared with the getter element with this composition ratio prepared by the traditional process, the suction rate and the suction volume are respectively increased by 16% and 19%.

Embodiment 3

[0025] Such as figure 1 As shown, Zr powder, Nb powder, and Ce powder are mixed with tert-butanol-based solvent (88% by mass of tert-butanol and 12% by mass of binder) according to the mass ratio of 80:15:5 to configure the absorption Gas powder slurry, wherein the mass percentage of Zr, Nb, Ce mixed powder is 78%. The slurry was poured into the mold, and then placed in a high and low temperature oven at -30°C for 30 minutes. After the green body of the getter element is formed, it is put into a vacuum box at a temperature of -15° C. for dealcoholization. The vacuum degree of the vacuum box is 150 Pa and kept for 18 hours. Put the dealcoholized getter element green body into the vacuum sintering furnace, and evacuate to 5×10 -4 Pa, heat up to 930°C for sintering. Compared with the getter element prepared by the traditional process, the suction rate and the suction volume are respectively increased by 17.5% and 19.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com