Formation method of semiconductor structure

A semiconductor and epitaxial layer technology, applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problem of difficulty in ensuring the stable performance of fin field effect transistors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

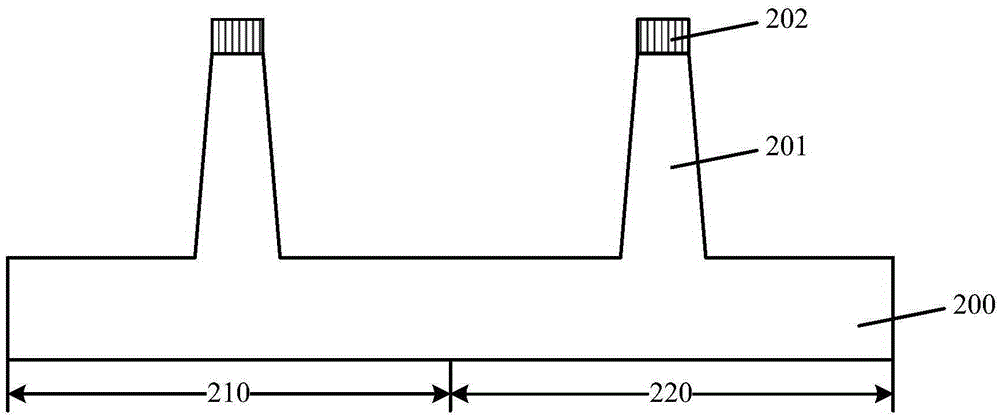

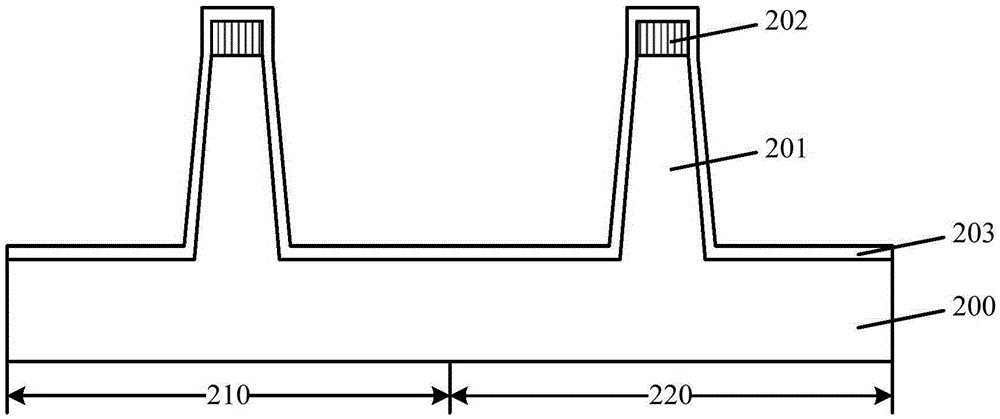

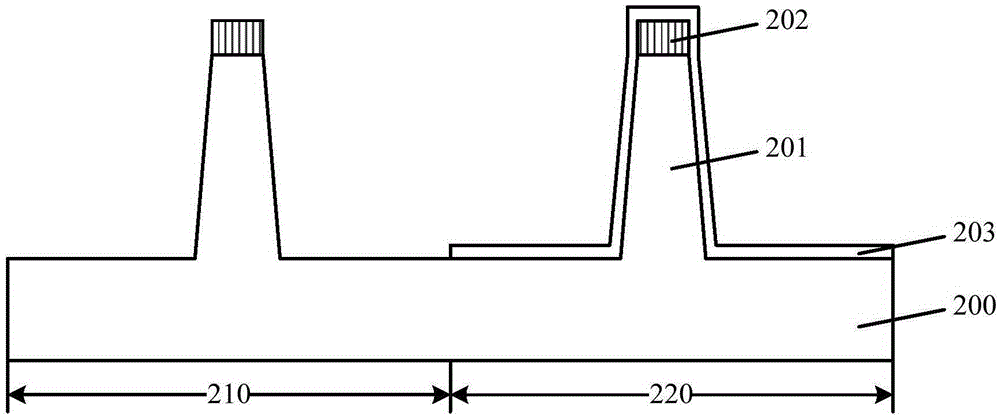

[0029] As mentioned in the background art, as the size of semiconductor devices continues to shrink, the manufacturing process of the FinFET is challenged, and it is difficult to ensure the stable performance of the FinFET.

[0030] After research, it is found that since the source region and the drain region of the fin field effect transistor are formed in the fin, as the size of the fin continues to shrink, the doping ions in the source region and the drain region will occur in both the horizontal and vertical directions. Diffusion, the dopant ions are more likely to diffuse to the bottom region of the fin, and cause the source region and the drain region to be short-circuited at the bottom region of the fin, thereby easily causing a punch through phenomenon (punch through) at the bottom region of the fin , making the bottom region of the fin prone to leakage current.

[0031] In order to overcome the bottom punch-through phenomenon, one method is to perform anti-puncture im...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com