Thermal management system and method of cuboid battery pack

A thermal management system and cuboid technology, applied in the field of thermal management, can solve the problems of low protection level of the battery box, weak ability to prevent thermal runaway, poor temperature uniformity of the battery, etc., to reduce interface contact resistance, increase heat dissipation contact area, and uniform temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

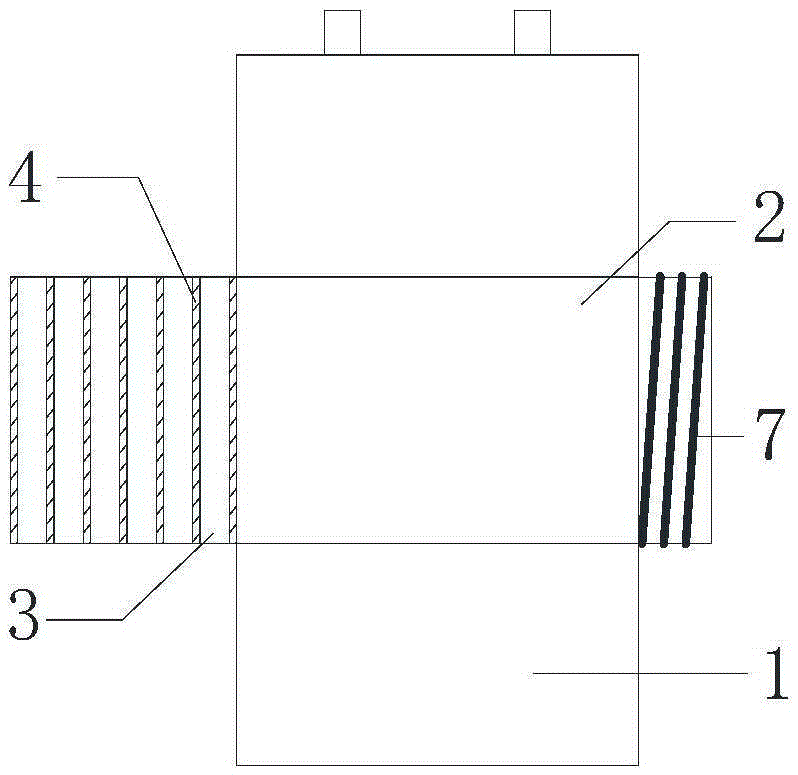

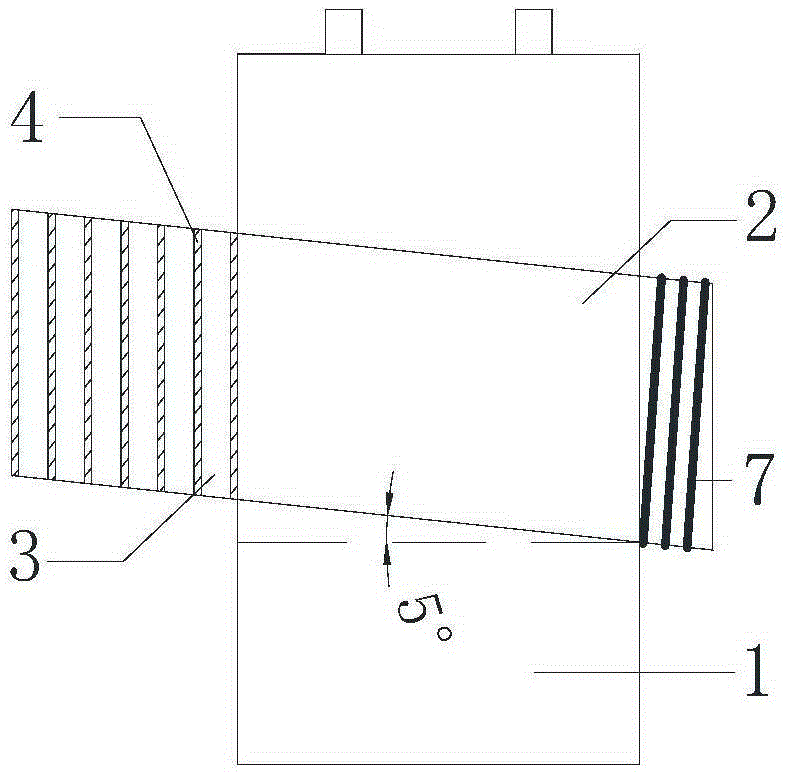

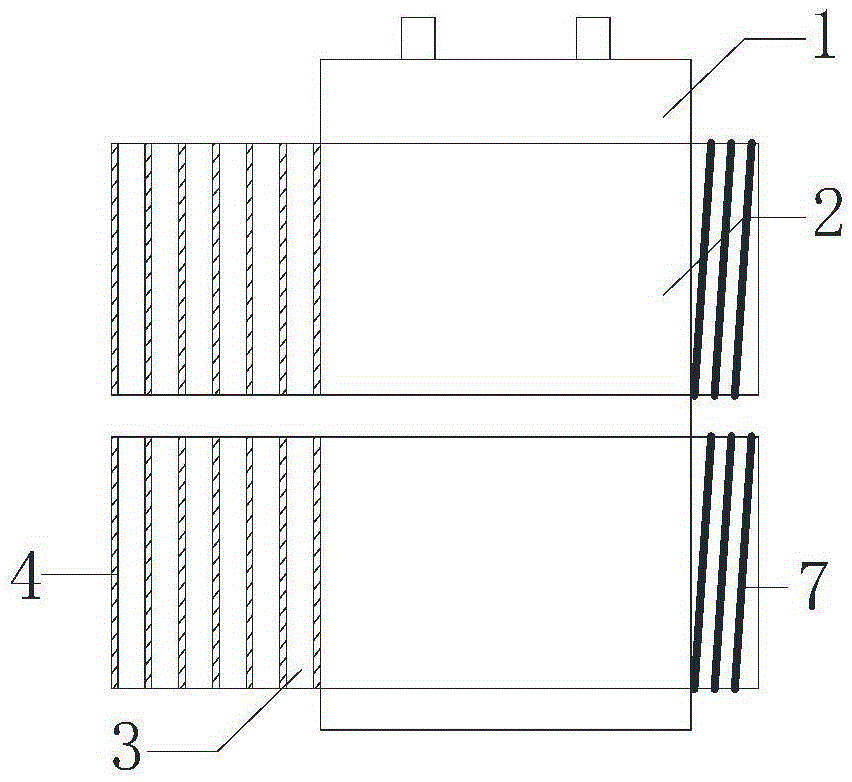

[0037] The present invention will be described below in conjunction with the accompanying drawings.

[0038] The present invention relates to a thermal management system for a rectangular parallelepiped battery pack on an electric vehicle, comprising a micro heat pipe array plate, a heat exchange element (preferably a heat sink or a heat exchanger) and a heat source, wherein the heat source can be an electric heating element or The heated fluid medium (it can be a hot fluid medium with a temperature higher than the battery temperature, such as hot air or hot liquid) pipeline, the electric heating element can be a resistance wire or an electric heating film; the micro heat pipe array plate is extruded from a metal material It has a plate-like structure with more than two micro heat pipe arrays arranged side by side. The equivalent diameter of each micro heat pipe in the micro heat pipe array is 0.2mm-2.5mm. The section is attached to the battery plate surface of the rectangular...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com