Metallurgical coke and method of manufacturing same

A technology of coke and coal blending, applied in the coking oven, petroleum industry, etc., can solve problems such as the method of controlling the pore structure that has not yet been known, and achieve the effects of stabilizing blast furnace operation, wide selection range, and alleviating resource constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0082]

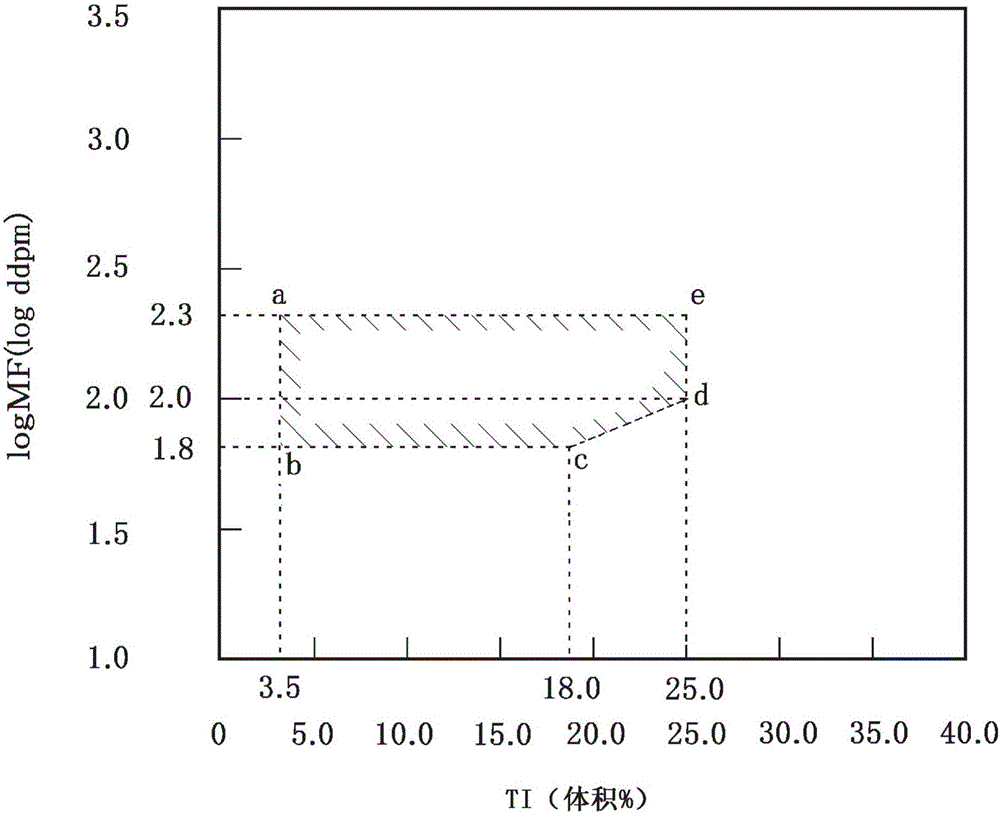

[0083] In this example, in order to examine the influence of the MF and TI of the blended coal on the coke strength, for the blended coals (1-1~6), (2-1~8), ( 3-1 to 6), (4-1 to 6), and (5-1 to 5) were dry-distilled, and the properties of the coke obtained were tested. The coal filling conditions are set to 8% by mass moisture content and 750kg / m bulk density 3 The constant condition of coal crushing particle size is set to 100% below 3mm. Carbonization conditions were set to a carbonization temperature of 1050° C. and a carbonization time of 6 hours. This dry distillation test uses a small electric furnace that can simulate an actual furnace, and evaluates the properties of coke obtained by cooling under a nitrogen atmosphere after carbonization. The drum intensity DI (150 / 15). It should be noted that in some tests, the CO of coke was also measured according to the ISO18894 method. 2 Post Response Strength (CSR).

[0084]Table 2 shows the properties of the co...

Embodiment 2

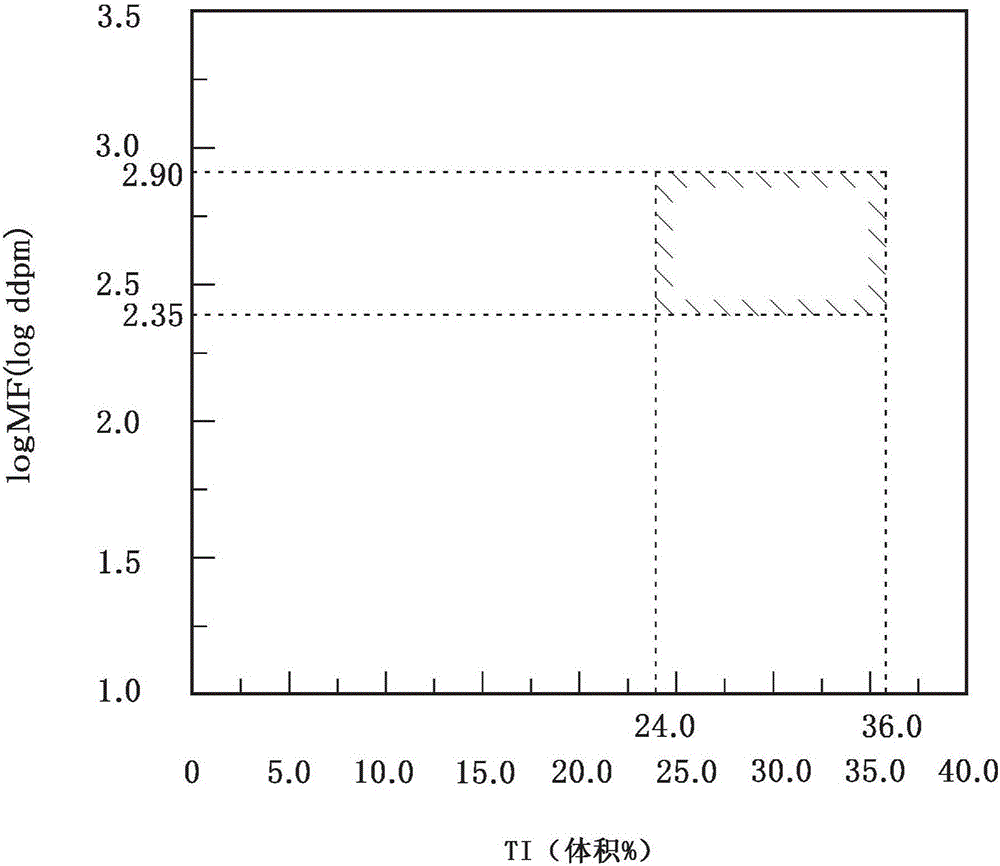

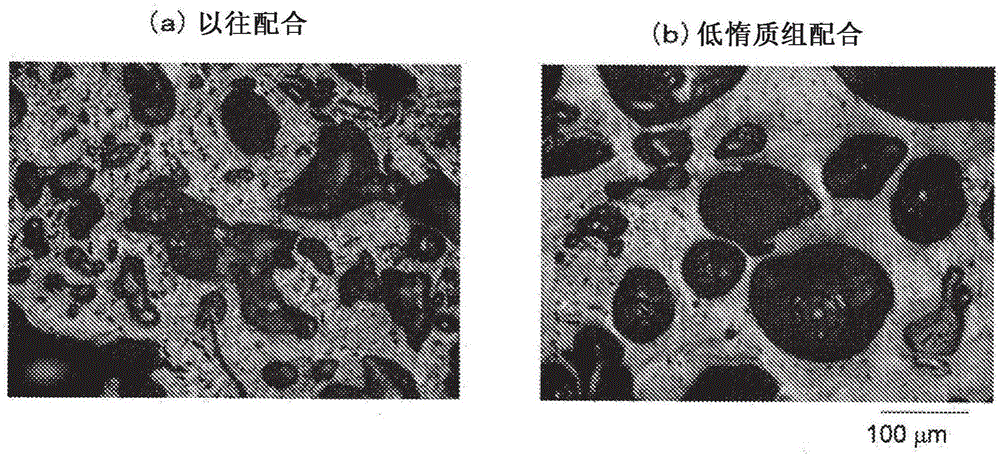

[0104] By the same method as in Example 1, cokes were produced by preparing mixed coals with Giselle maximum fluidity logMF=2.2log ddpm and average maximum reflectance Ro, and the strength of the obtained cokes was examined. Tables 8 to 10 show the blending composition of each coal blend (the dry standard blending ratio (mass %) of each coal) and the results of the dry distillation test. Ro, logMF, and TI in the table are weighted averages obtained from the Ro, logMF, and TI of each product blended and the compounding ratio of each product. From Tables 8 to 10, it can be confirmed that the cases where the average reflectance Ro is 1.20%, 1.10%, and 0.95% are the same as the case where the average maximum reflectance Ro shown in Example 1 is 1.00%. Coal blending in the range of TI ≥ 3.5% by volume yields coke with high circularity of coarse pores and drum strength DI (150 / 15) of 82.7 or more. It is considered that Ro will not have a great influence on the preferred ranges of TI...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com