Sisal hemp residue dietary fibers and preparation method thereof

A technology of dietary fiber and soluble dietary fiber, applied in the direction of food science, etc., to achieve the effect of low production cost, simple operation and strong adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

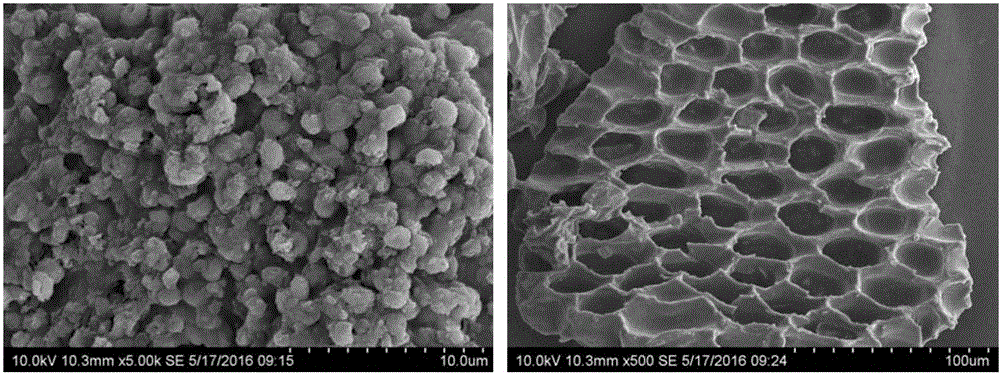

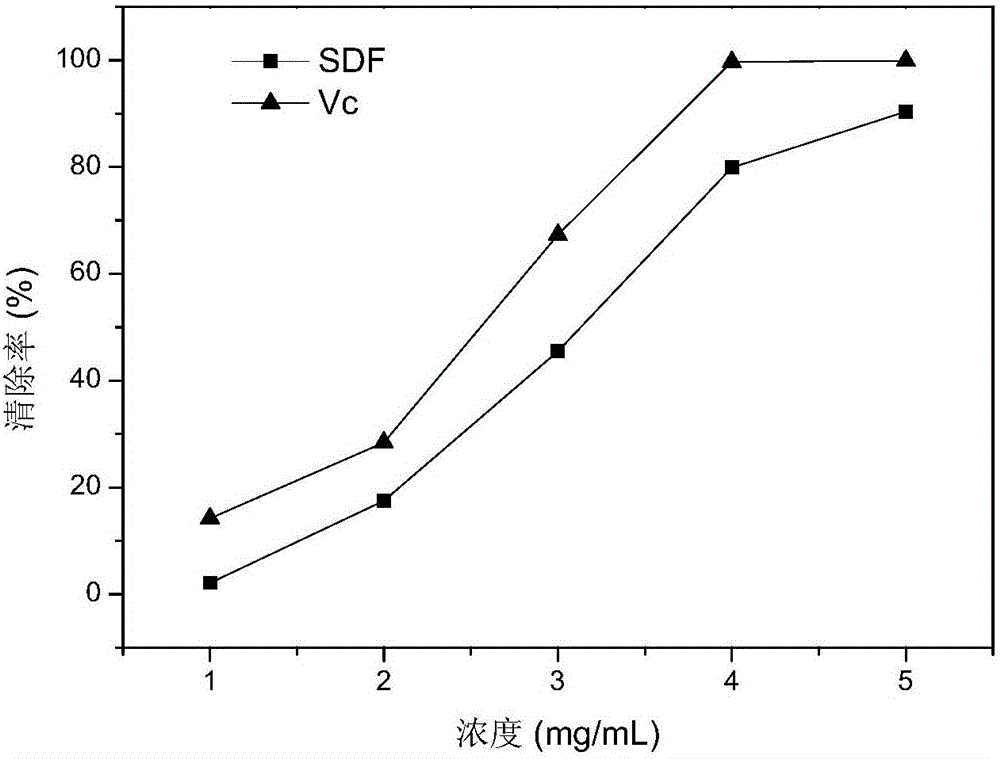

Image

Examples

Embodiment 1

[0033] The sisal slag after fiber extraction was washed with clean water several times to remove impurities, and air-dried at 60°C for 10 hours, and the dried sisal slag was mechanically crushed with a pulverizer to obtain sisal slag powder, which was sealed in a sample bag , stored in a dry place at room temperature; take 10g of sisal residues and place them in a Soxhlet extractor, use 150mL of absolute ethanol as a solvent, and extract at 60°C until the color of the solvent in the extractor is colorless, then take out the sisal residues, Blast drying at 60°C for 12 hours; add deionized water to the pretreated sisal slag powder at a solid-to-liquid ratio of 1:10 (W / V, g / ml), and adjust to a solution with 1mol / L hydrochloric acid The pH is 2, and mechanically stirred in an oil bath at 70°C for 60 minutes; then the hydrolyzate is centrifuged to obtain two parts, the supernatant I and the precipitate I, and the acid hydrolysis process is repeated 3 times, and the supernatant I an...

Embodiment 2

[0036]The sisal slag after fiber extraction was washed with clean water several times to remove impurities, and air-dried at 60°C for 10 hours, and the dried sisal slag was mechanically crushed with a pulverizer to obtain sisal slag powder, which was sealed in a sample bag , stored in a dry place at room temperature; take 8g of sisal residues and place them in a Soxhlet extractor, use 100mL of absolute ethanol as a solvent, and extract at 55°C until the color of the solvent in the extractor is colorless, then take out the sisal residues, Blast drying at 60°C for 12 hours; add deionized water to the pretreated sisal slag powder at a solid-to-liquid ratio of 1:15 (W / V, g / ml), and adjust to a solution with 1mol / L hydrochloric acid The pH is 1.5, and mechanically stirred in an oil bath at 80°C for 120 minutes; then the hydrolyzate is centrifuged to obtain two parts, the supernatant I and the precipitate I, and the acid hydrolysis process is repeated 3 times, and the supernatant I a...

Embodiment 3

[0039] The sisal slag after fiber extraction was washed with clean water several times to remove impurities, and air-dried at 60°C for 10 hours, and the dried sisal slag was mechanically crushed with a pulverizer to obtain sisal slag powder, which was sealed in a sample bag , stored in a dry place at room temperature; take 15g of sisal residues and place them in a Soxhlet extractor, use 200mL of absolute ethanol as a solvent, and extract at 60°C until the color of the solvent in the extractor is colorless, then take out the sisal residues, Blast drying at 60°C for 12 hours; add deionized water to the pretreated sisal slag powder at a solid-to-liquid ratio of 1:20 (W / V, g / ml), and adjust to a solution with 1mol / L hydrochloric acid The pH is 1.5, and mechanically stirred in an oil bath at 90°C for 90 minutes; then the hydrolyzate is centrifuged to obtain two parts, the supernatant I and the precipitate I, and the acid hydrolysis process is repeated 3 times, and the supernatant I ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com