Two-stage shell-breaking type peanut sheller

A shelling machine and shell breaking technology, applied in the field of agricultural machinery, can solve the problems of large elastic deformation of rubber protrusions, affecting shelling efficiency, and shell breaking rate, etc. The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

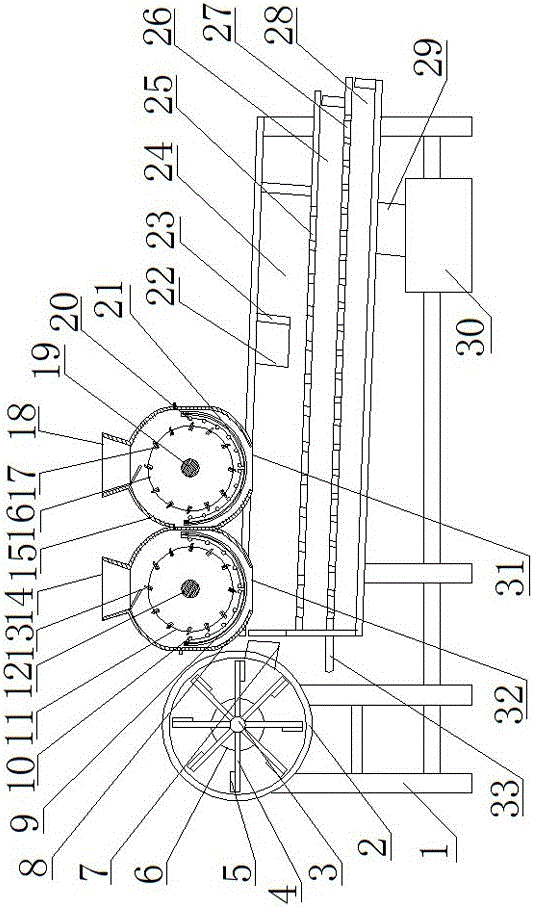

Embodiment 1

[0020] Such as figure 1 As shown, the two-stage shell-breaking type peanut sheller of the present invention includes a frame 1, a peanut shell-breaking mechanism, a winnowing mechanism and a screening mechanism, and the peanut shell-breaking mechanism includes a primary shell-breaking mechanism and a secondary shell-breaking mechanism , the screening mechanism is provided with an export mechanism for uncracked peanuts. The structure of the primary shell-breaking mechanism and the secondary shell-breaking mechanism is basically the same, including shell breaking drums 11, 16, grids 10, 20, and a housing 8 with feed ports 14, 18 and discharge ports 32, 31. , 15, the shell breaking cylinder 11, 16 peripheral side is provided with such as clamping rubber sheet material or other elastic peeling knives 13, 17, the shell breaking cylinder 11, 16 passes through the cylinder shaft 12, 19 and the housing 8, 15 connect. The grids 10, 20 can adopt a squirrel-cage structure, and are mova...

Embodiment 2

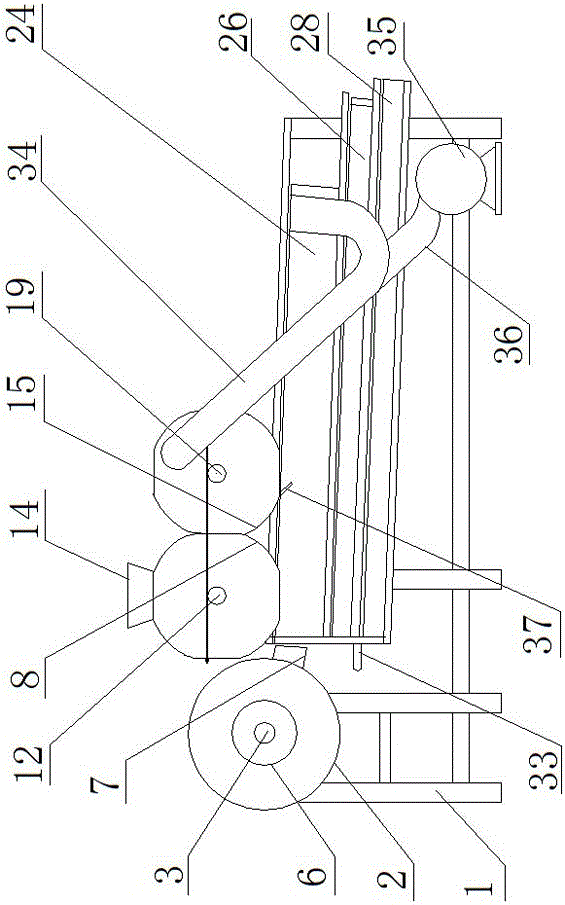

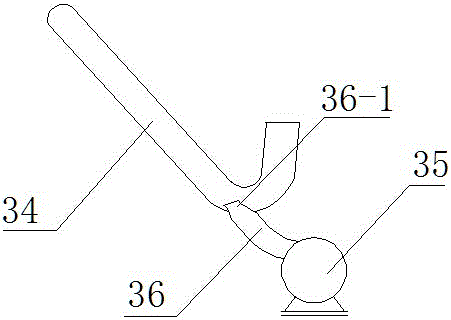

[0023] combine figure 1 see figure 2 , image 3 , as an improvement of the uncracked peanut export mechanism, it may include a feed pipe 34 and an air supply pipe 36 connected thereto, and the two ends of the feed pipe 36 are respectively connected to the discharge port of the uncracked peanuts and the secondary crack mechanism. The casing 15 is connected and communicated, and the air supply pipe 36 is connected with a blower 35 . In this embodiment, the top of the casing 15 may not be provided with a feed port, and the airflow entered by the feed pipe 34 can be discharged from the discharge port 31, directly increasing the wind power of the winnowing, and correspondingly reducing the power consumption of the winnowing mechanism. In order to realize this increase To improve the effectiveness of the amount, a deflector 37 can also be arranged on one side of the discharge port 31. Through wind conveying, it not only replaces the manual feeding of uncracked peanuts, reduces l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com