Compound ceftiofur cream and preparation method thereof

A technology of thiifur cream and ceftiofur hydrochloride, which is applied in the directions of ointment delivery, pharmaceutical formulation, aerosol delivery, etc., can solve the problems of limited types of injections, ointment is not included, etc., and achieves stable properties and low resistance rate , the effect of fast action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

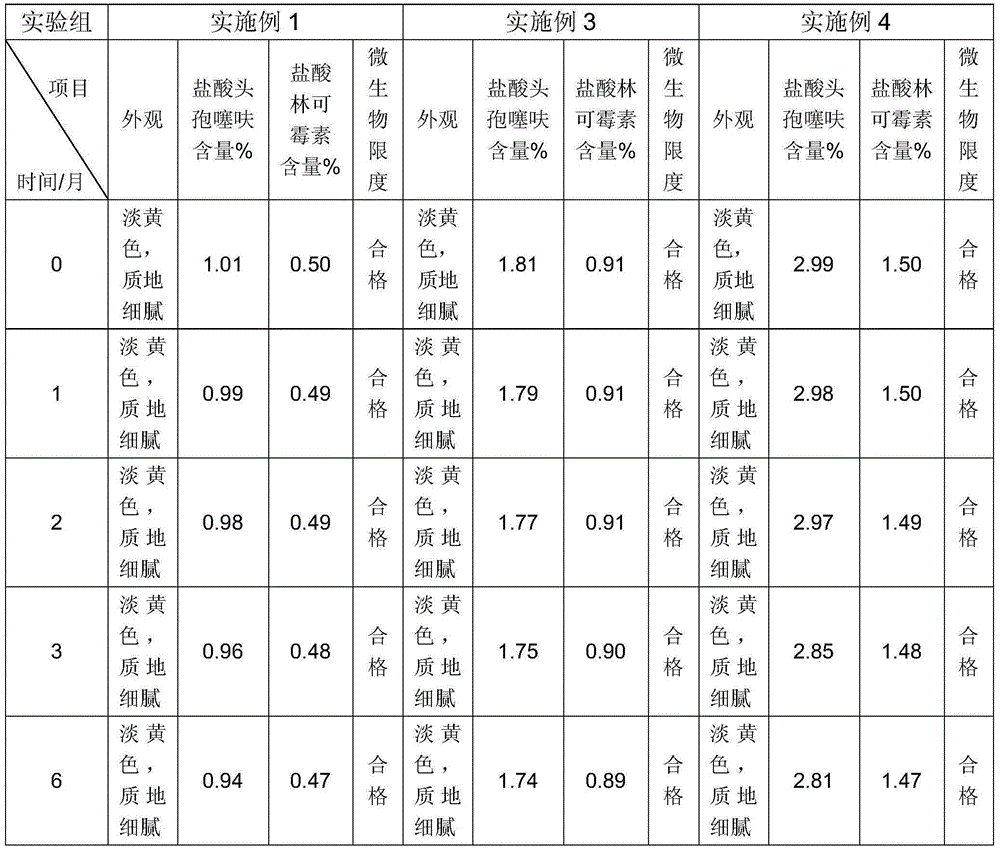

Embodiment 1

[0036] 100g of compound cream containing ceftiofur hydrochloride and lincomycin hydrochloride, consisting of the following ingredients in percentage by weight: ceftiofur hydrochloride 1g, lincomycin hydrochloride 0.5g, stearic acid 6g, monostearic acid Glycerides 13g, Lanolin 3g, Liquid Paraffin 40.0g, White Vaseline 12g, Span 805g, Tween 802g, Poloxamer 0.1g, Glycerin 1g, Propylene Glycol 2g, Vitamin E 0.1g, Ethyl Paraben 0.08g , Purified water is added to 100g.

[0037] The preparation steps are:

[0038] A: Mixed micronized powder: Micronized ceftiofur hydrochloride and lincomycin hydrochloride, passed through a 200 mesh sieve, and mixed well.

[0039] B: Preparation of oil phase: take stearic acid, glyceryl monostearate, lanolin, liquid paraffin, white petrolatum, Span 80, stir at 700r / min, and heat to melt at 60°C in a water bath.

[0040] C: Water phase preparation: Disperse the solid of step A uniformly in glycerin and propylene glycol, and then dissolve the above solution wit...

Embodiment 2

[0043] 100g of a compound cream containing ceftiofur hydrochloride and lincomycin hydrochloride, consisting of the following ingredients in percent by weight: ceftiofur hydrochloride 2.4g, lincomycin hydrochloride 1.2g, stearic acid 9g, monostearic acid Acid glycerides 14g, lanolin 4g, liquid paraffin 20.0g, white petrolatum 5g, spar 803g, Tween 802.5g, poloxamer 0.08g, glycerol 1.5g, propylene glycol 1.3g, vitamin E 0.05g, bisulfite Sodium 0.07g, ethyl paraben 0.06g, sodium benzoate 0.06g, purified water is added to 100g.

[0044] The preparation steps are:

[0045] A: Mixed micronized powder: Micronized ceftiofur hydrochloride and lincomycin hydrochloride, passed through a 300-mesh sieve, and mixed well.

[0046] B: Preparation of oil phase: Take stearic acid, glyceryl monostearate, lanolin, liquid paraffin, white petrolatum, and Span 80 in a container, stir at 900r / min, and heat to melt at 70°C in a water bath.

[0047] C: Preparation of water phase: disperse the solid of step A u...

Embodiment 3

[0050] 100g of a compound cream containing ceftiofur hydrochloride and lincomycin hydrochloride, consisting of the following ingredients in percentages by weight: ceftiofur hydrochloride 1.8g, lincomycin hydrochloride 0.9g, stearic acid 10g, monostearic acid Acid glycerides 16g, lanolin 3.5g, liquid paraffin 30.0g, white petrolatum 10g, span 803.5g, Tween 801.5g, poloxamer 0.06g, sodium lauryl sulfate 0.09g, glycerol 2.5g, propylene glycol 1.6g, vitamin E 0.06g, ethyl paraben 0.07g, sodium benzoate 0.05g, purified water to 100g.

[0051] The preparation steps are:

[0052] A: Mixed micronized powder: Micronized ceftiofur hydrochloride and lincomycin hydrochloride, passed through a 200-mesh sieve, and mixed well.

[0053] B: Oil phase configuration: Take liquid stearic acid, glyceryl monostearate, lanolin, paraffin, white petrolatum, and Span 80 into a container, stir at 900r / min, and heat to melt at 80°C in a water bath.

[0054] C: Water phase configuration: disperse the solid of st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com