Preparation method of air filtering material capable of releasing fragrance

An air filter material and fragrance technology, which is applied in the field of nanofibers, can solve problems such as easy generation of odor, achieve the effect of increasing fragrance release, broad application prospects, and improving air filtration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of an air filter material capable of releasing fragrance, the steps are as follows:

[0028] 1) To prepare a solution, disperse the powdery fragrance-releasing substance agarwood in formic acid with a particle size of 0.2 μm, ultrasonicate for 5 minutes, and stir for 5 minutes to form a homogeneous dispersion, the mass fraction of the fragrance-releasing substance is 0.01wt%; then the molecular weight The large polymer nylon 6, with a weight average molecular weight of 200,000 Daltons, and the small molecular weight polymer nylon 66, with a weight average molecular weight of 10,000 Daltons, were added to the dispersion, ultrasonicated for 5 minutes, and stirred for 3 hours Form a stable spinning solution; the mass fraction of nylon 6 is 8wt%; the mass fraction of nylon 66 is 8wt%;

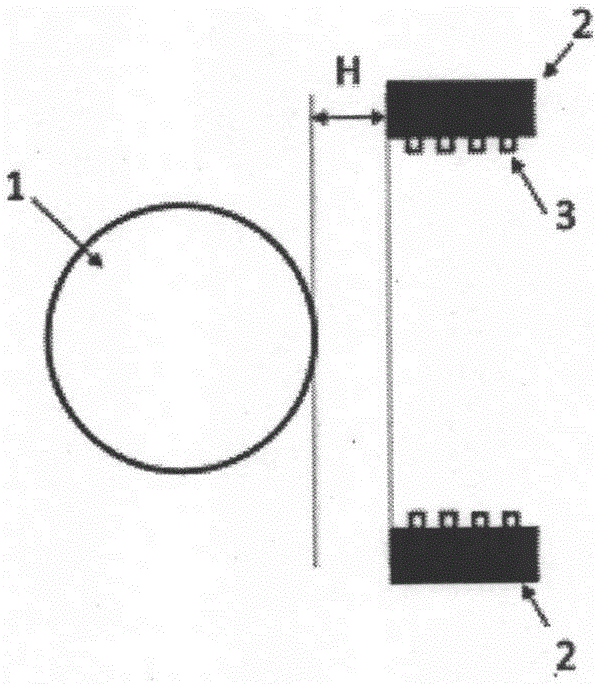

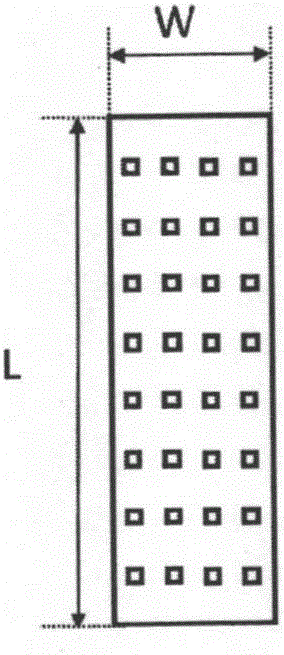

[0029] 2) Electrospinning, put the spinning solution prepared in step 1) in the liquid storage device, set the electrospinning parameters, the electrospinning parameters...

Embodiment 2

[0033] A preparation method of an air filter material capable of releasing fragrance, the steps are as follows:

[0034]1) To prepare a solution, disperse the powdered fragrance-releasing substance wisteria in tetrahydrofuran, with a particle size of 0.3 μm, sonicate for 10 minutes, and stir for 10 minutes to form a homogeneous dispersion, and the mass fraction of the fragrance-releasing substance is 0.05 wt %; Polymethyl methacrylate, a high molecular weight polymer with a weight average molecular weight of 220,000 daltons, and a high molecular weight polyvinyl acetate with a weight average molecular weight of 20,000 daltons are added to the dispersion, Ultrasound for 10 minutes, stirring for 8 hours to form a stable solution; the mass fraction of polymethylmethacrylate is 10wt%; the mass fraction of polyvinyl acetate is 10wt%;

[0035] 2) Electrospinning, put the solution prepared in step 1) in the liquid storage device, set the electrospinning parameters, the electrospinnin...

Embodiment 3

[0039] A preparation method of an air filter material capable of releasing fragrance, the steps are as follows:

[0040] 1) To prepare a solution, disperse the powdery fragrance-releasing substance Elemis in N,N-dimethylformamide, the particle size is 0.5 μm, ultrasonic 15min, and form a homogeneous dispersion after stirring for 15min. The quality of the fragrance-releasing substance Fraction is 1wt%; Then the polymer nylon 6 with big molecular weight, weight-average molecular weight is 240,000 daltons, and the little polymer polycaprolactone with molecular weight, weight-average molecular weight is 30,000 daltons, joins in In the dispersion, a stable solution was formed after ultrasonication for 15 minutes and stirring for 10 hours; the mass fraction of nylon 6 was 15 wt %; the mass fraction of polycaprolactone was 10 wt %;

[0041] 2) Electrospinning, place the solution prepared in step 1) in the liquid storage device, set the electrospinning parameters, the electrospinning ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com