Multi-source control vehicle-mounted spray method and multi-source control spray system

A multi-source control and sprinkler system technology, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve problems such as the inability to accurately locate the source of noise and dust, the inability to automatically adjust the size of the water flow, and the dust removal of construction objects. , to achieve the effect of small space, convenient construction and high labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

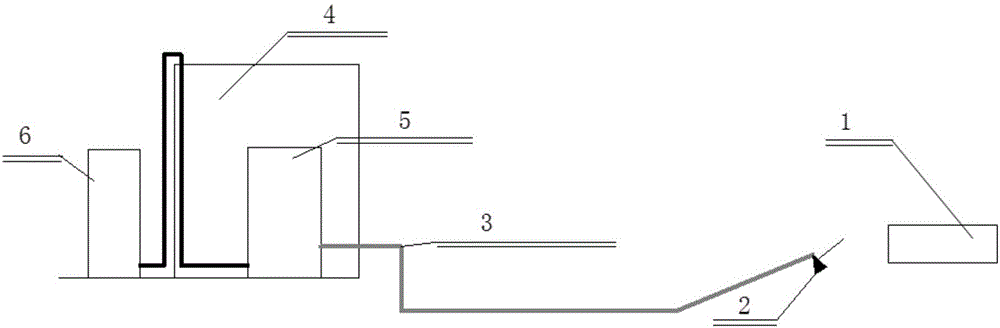

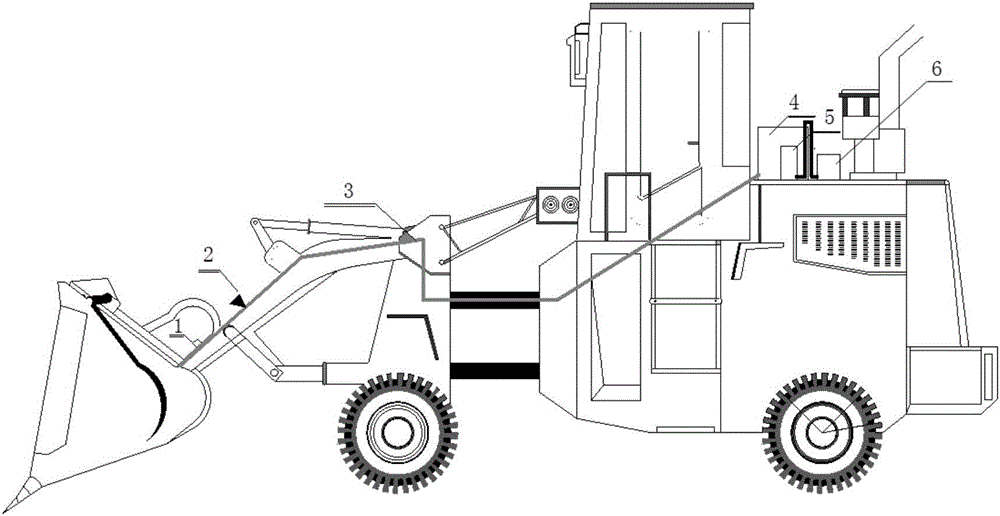

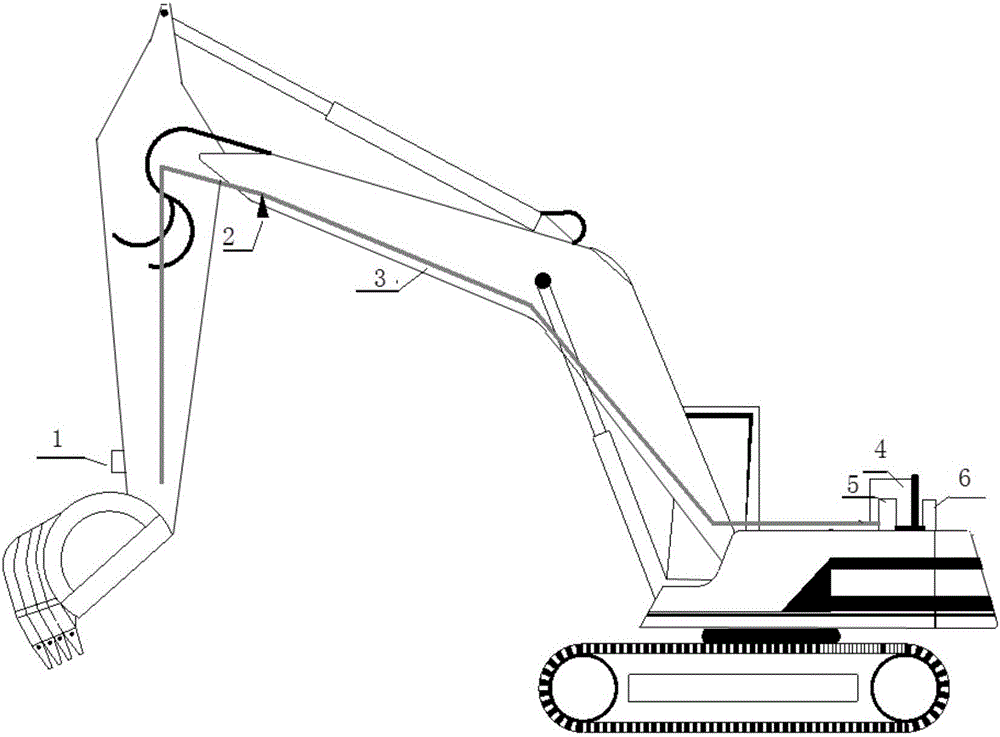

[0026] The present invention will be further described below in conjunction with drawings and embodiments.

[0027] The invention provides a multi-source control vehicle spraying method, comprising the following steps:

[0028] (1) When the engineering vehicle is working, the sensor located in the mechanical working part of the engineering vehicle collects the sound source signal, seismic source signal and dust source signal in real time;

[0029] (2) The sensor sends the sound source signal, the vibration source signal and the dust source signal to the control unit located in the body part of the engineering vehicle;

[0030] (3) The control unit controls the work of the water pump located on the body of the engineering vehicle according to the sound source signal, the seismic source signal and the dust source signal, and supplies water to the sprinkler head with an appropriate flow rate to spray the construction target for noise reduction and dust removal.

[0031] The sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com