Laser sealing method and sealing body of glass and Kovar alloy

A technology of alloy and glass, which is applied in the field of sealing of heterogeneous materials, can solve the problems of low connection strength, and achieve the effect of avoiding glass bursting, avoiding excessive heat input, tight connection and sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

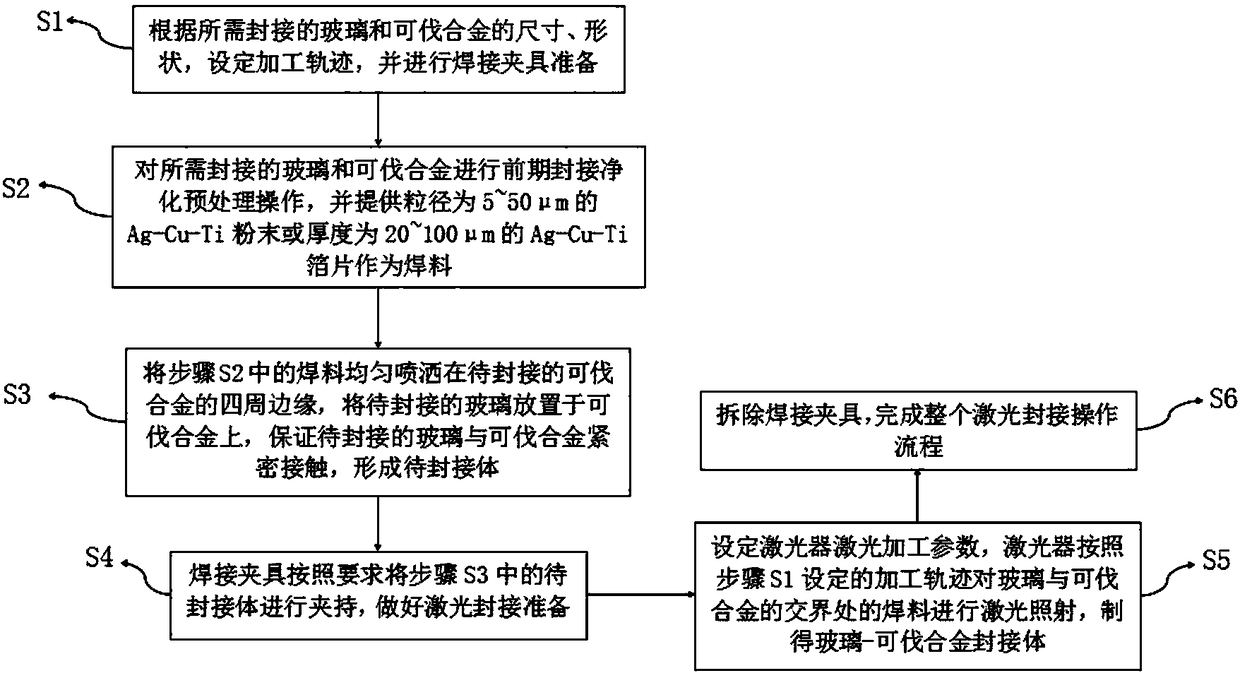

[0038] S1. According to the size and shape of the glass and Kovar alloy to be sealed, set the processing track and prepare the welding fixture. In this embodiment, the glass to be sealed is a window glass sample of 8*20*4 mm, and the Kovar alloy is a Kovar alloy steel plate of 10*25*1.5 mm.

[0039] S2. Perform pre-sealing purification pretreatment on the glass and Kovar alloy to be sealed, and provide Ag-Cu-Ti powder with a particle size of 5-50 μm or Ag-Cu-Ti foil with a thickness of 20-100 μm sheet as solder.

[0040] Among them, the pre-sealing and purification pretreatment operations respectively refer to degreasing and degreasing the Kovar alloy to be sealed and then performing oxidation treatment; washing the glass to be sealed with clean water, and then cooling and air-drying.

[0041]The Ag-Cu-Ti powder or Ag-Cu-Ti foil as solder comprises the following components by mass fraction: 66% Ag, 30% Cu, 4.0% Ti, and the Ag used in the present invention -Cu-Ti powder or Ag...

Embodiment 2

[0048] The difference between this embodiment and Embodiment 1 is that the components of the solder used include 72% Ag, 25% Cu, and 3.0% Ti by mass fraction, the thickness of the solder is 32 μm, and the wavelength is 1000 nm. Nd-YAG laser, the processing trajectory set by the Nd-YAG laser is the scanning length of 78mm (X direction) and 18mm (Y direction), and the laser parameters are set as: laser scanning speed 40mm min -1 , the laser power is 130W, the pulse width is 2.5ms, the frequency is 10Hz, the number of scans is 1 to 3, and the laser sealing operation is performed on the glass and Kovar alloy at a distance of 1mm from the solder.

[0049] According to tests, the shear strength of the glass-Kovar alloy sealing body obtained by adopting the laser sealing method of this embodiment can reach 34 MPa.

Embodiment 3

[0051] The difference between this embodiment and Embodiment 1 is that the components of the solder used include 79% Ag, 20% Cu, and 1.0% Ti by mass fraction, the thickness of the solder is 45 μm, and the wavelength is 940 nm. The semiconductor laser, the processing trajectory set by the semiconductor laser is the scanning length of 78mm (X direction) and 18mm (Y direction), and the laser parameters are set as: laser scanning speed 160mm min -1 , the laser power is 160W, the pulse width is 1.8ms, the frequency is 8Hz, the number of scans is 1 to 3, and the laser sealing operation is performed on the glass and Kovar alloy at a distance of 3mm from the solder.

[0052] According to tests, the shear strength of the glass-Kovar alloy sealing body obtained by adopting the laser sealing method of this embodiment can reach 41 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com