Fully automatic car carpet production line and production method

A technology for automobile carpets and production lines, which is applied to vehicle parts, special positions of vehicles, manufacturing tools, etc. It can solve the problems that the quality and performance of finished products cannot meet higher standards, the degree of automation is low, and the equipment is not closely matched. The effect of saving manpower and material resources, reducing manpower waste and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

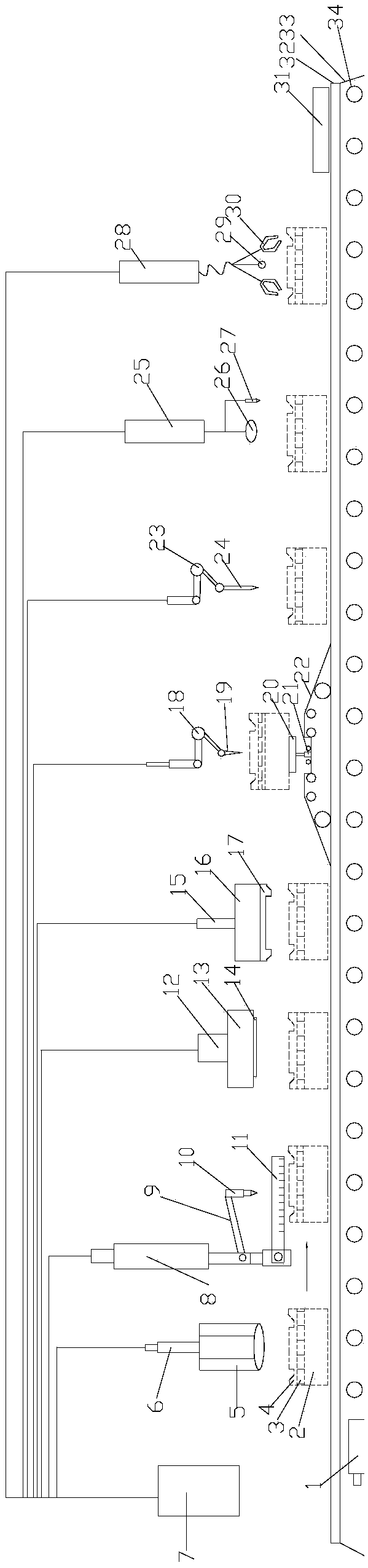

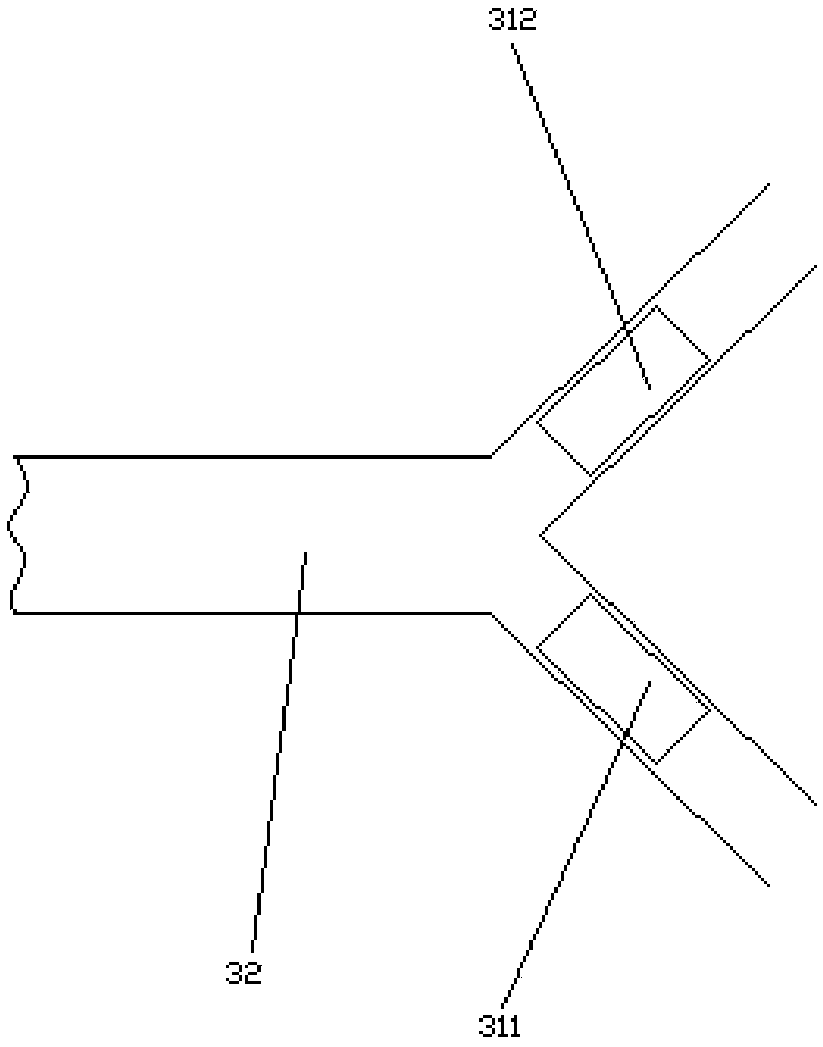

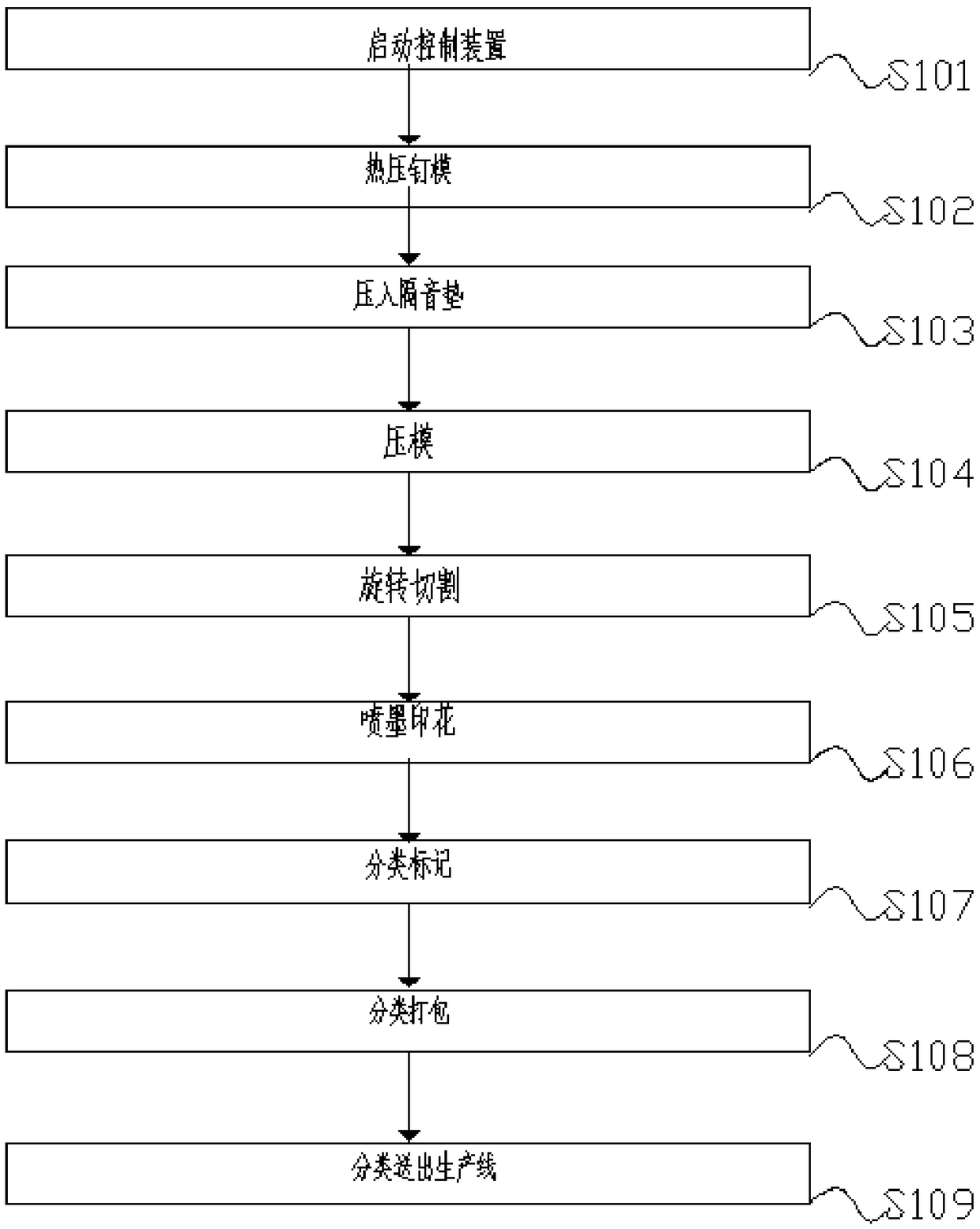

[0029] Depend on figure 1 with image 3As shown, the present invention provides a fully automatic automobile carpet production line and production method, including a frame 33 and a console 7; the tail end of the frame 33 is provided with two outlets, and an intermittent The conveying rail 32 of type motion, described conveying rail 32 below is provided with roller, and described frame 33 bottoms are equipped with roller driving device, and described roller driving device comprises driving motor 1 and roller driving mechanism 34, and roller driving mechanism 34 passes roller Drive the conveying rail 32 to move in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com