Method for preparing sodium-ion battery electrode carbon material by using laurel potato

A technology for sodium ion batteries and falling sunflowers, which is applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve the problems of large challenges and slow progress in the negative electrode materials of sodium ion batteries, and achieve low cost and enhanced battery cycle The effect of performance and operation is simple and easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing sodium-ion battery electrode carbon material by utilizing laurel potato, comprising the following steps:

[0032] Step 1. After washing the laurel potatoes with ethanol and deionized water respectively, place them in a blast drying oven to dry at 60°C for 24 hours;

[0033] Step 2. Place the dried laurel potatoes in a porcelain boat, use a high-temperature tube furnace to heat up to 800°C at a rate of 30°C / min under the protection of an inert atmosphere, and then heat-preserve and carbonize for 4 hours;

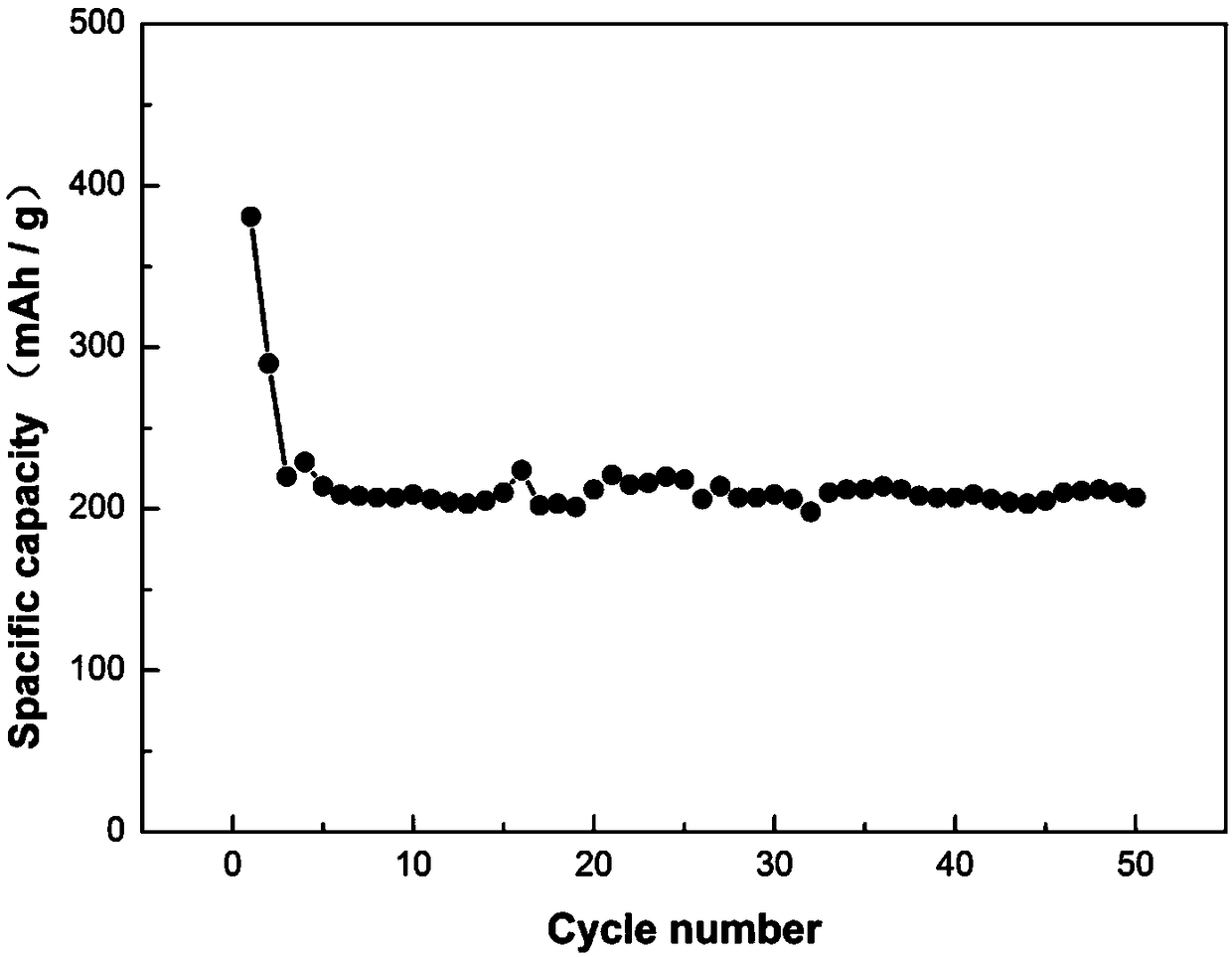

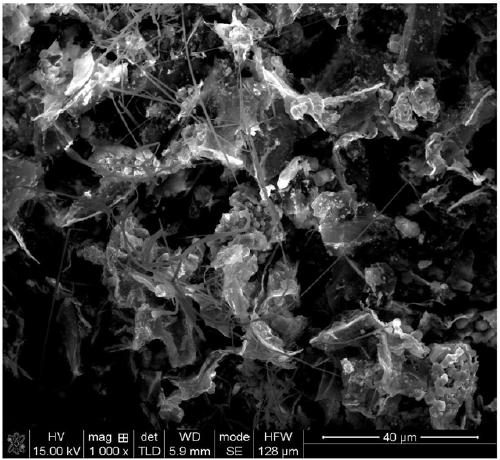

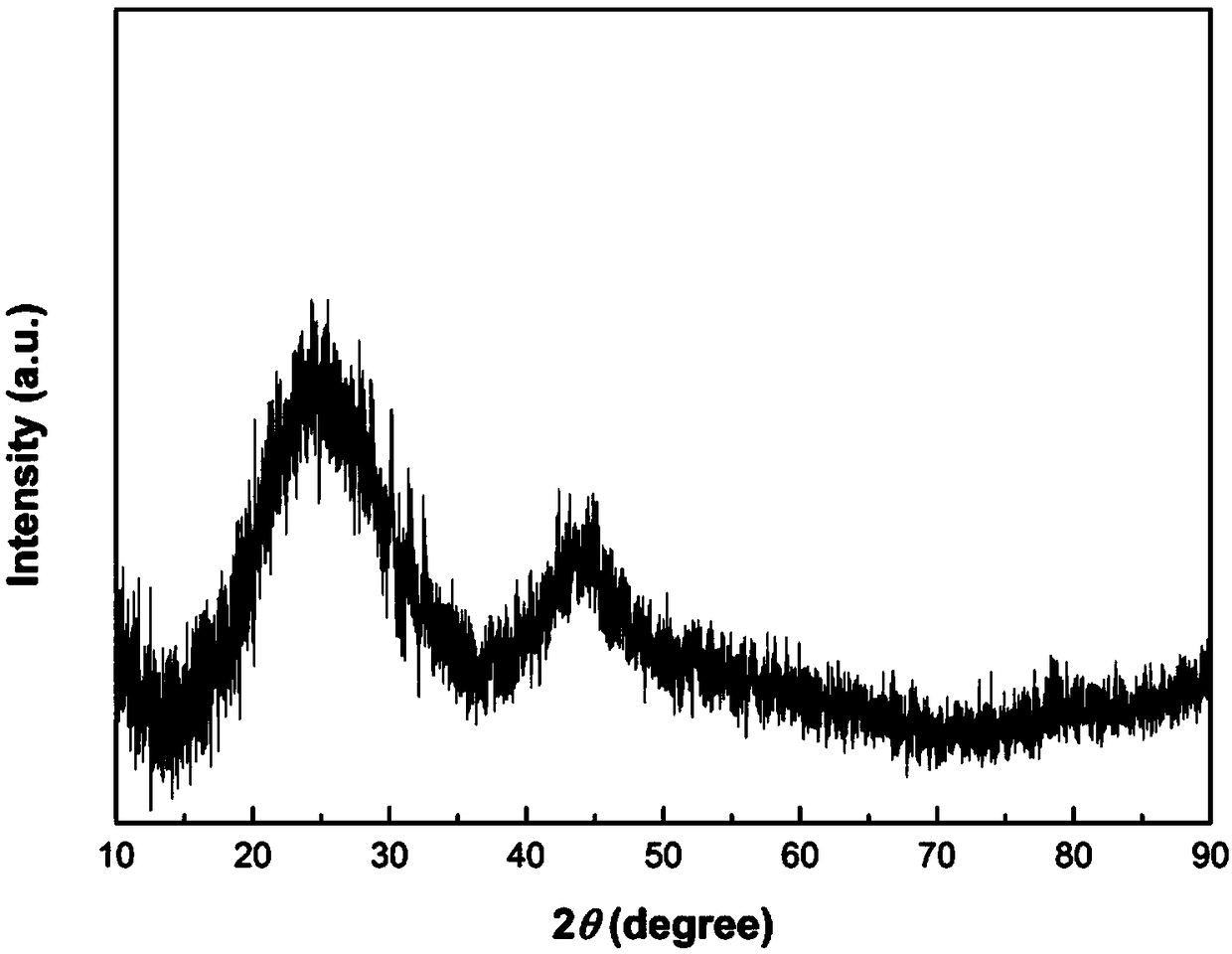

[0034] Step 3. Grinding the carbonized yam into powder, and then sieving it through a 100-mesh sieve to obtain a yam-derived carbon powder with uniform particles, which is the electrode carbon material for sodium-ion batteries; image 3 It is the XRD pattern of the derived carbon of Luokui potato prepared in Example 1. Where the abscissa is the angle and the ordinate is the relative intensity. Depend on figure 1 It can be seen that there are o...

Embodiment 2

[0036] A method for preparing sodium-ion battery electrode carbon material by utilizing laurel potato, comprising the following steps:

[0037] Step 1. After washing the laurel potatoes with ethanol and deionized water respectively, place them in a blast drying oven to dry at 60°C for 24 hours;

[0038] Step 2. Place the dried laurel potatoes in a porcelain boat, use a high-temperature tube furnace to heat up to 750°C at a rate of 15°C / min under the protection of an inert atmosphere, and then heat-preserve and carbonize for 12 hours;

[0039] Step 3: Grind the carbonized yam into powder, and then sieve it through a 100-mesh sieve to obtain a yam-derived carbon powder with uniform particles, which is the electrode carbon material for sodium ion batteries.

Embodiment 3

[0041] A method for preparing sodium-ion battery electrode carbon material by utilizing laurel potato, comprising the following steps:

[0042] Step 1. After washing the laurel potatoes with ethanol and deionized water respectively, place them in a blast drying oven to dry at 60°C for 24 hours;

[0043] Step 2. Put the dried succulents in a porcelain boat, use a high-temperature tube furnace to heat up to 850°C at a rate of 20°C / min under the protection of an inert atmosphere, and then heat-preserve and carbonize for 3 hours;

[0044] Step 3: Grind the carbonized yam into powder, and then sieve it through a 100-mesh sieve to obtain a yam-derived carbon powder with uniform particles, which is the electrode carbon material for sodium ion batteries.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com