Method for mud fast sedimentation conditioning and solid-liquid separation

A solid-liquid separation and slurry technology, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as low efficiency, achieve high efficiency, short time, and strengthen the effect of dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

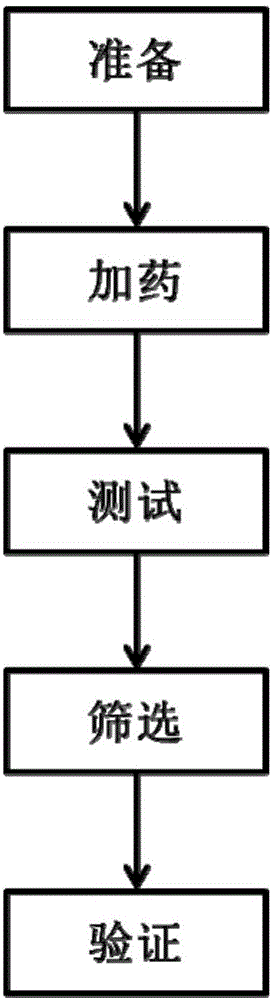

[0025] This embodiment provides a description of a method for rapid mud conditioning and sedimentation solid-liquid separation, including the following steps:

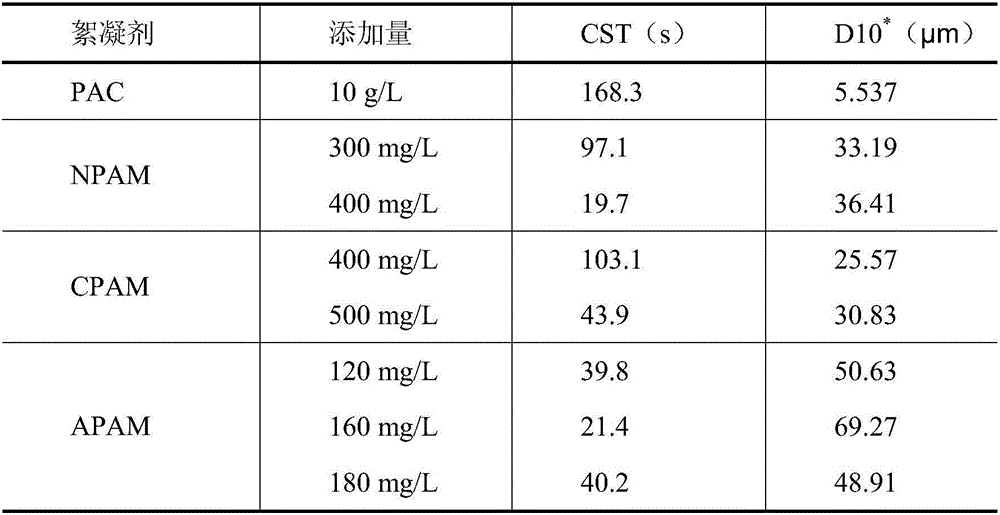

[0026] Step 1, preparation, includes engineering mud sampling and flocculant solution preparation. The mud is selected from the groove wall mud of a construction site on Guangfu Road in Shanghai, with a moisture content of 74wt% and an initial CST value of 327.5s. Polyaluminum chloride (PAC), when used, is prepared into a solution with a concentration of 5wt%; cationic polyacrylamide (CPAM), nonionic polyacrylamide (NPAM), and anionic polyacrylamide (APAM) are prepared with a concentration of 0.1wt when used %The solution.

[0027] Step 2, dosing, adding different amounts of flocculant combinations to the mud and fully stirring to flocculate to form alum flowers.

[0028] Step 3, test, take the mud that forms alum flower and stir and carry out capillary water absorption time (CST) (model 304B, Britain Triton Electron...

Embodiment 2

[0036] This embodiment provides a description of a method for rapid mud conditioning and sedimentation solid-liquid separation, including the following steps:

[0037] Step 1, preparation, includes engineering mud sampling and flocculant solution preparation. The mud is bored pile mud at a construction site in Qiantan, Pudong, Shanghai, with a moisture content of 67wt% and an initial CST value of 404.8s. Polyaluminum chloride (PAC) is prepared into a solution with a concentration of 5wt% when used; cationic polyacrylamide (CPAM), nonionic polyacrylamide (N PAM), and anionic polyacrylamide (APAM) are prepared with a concentration of 0.1 wt% solution.

[0038] Step 2, dosing, adding different amounts of flocculant combinations to the mud and fully stirring to flocculate to form alum flowers.

[0039] Step 3, test, take the mud that forms alum flower and stir and carry out capillary water absorption time (CST) (model 304B, Britain Triton Electronics Ltd) test and laser diffract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com