Glass fusion bonding method, as well as manufacturing method and manufacturing equipment of vacuum glass

A vacuum glass and glass fusion technology, applied in glass manufacturing equipment, glass molding, glass re-molding and other directions, can solve the problems of uneven stress, high damage rate, affecting the yield rate, etc., to improve the production efficiency, use Longer life and higher productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

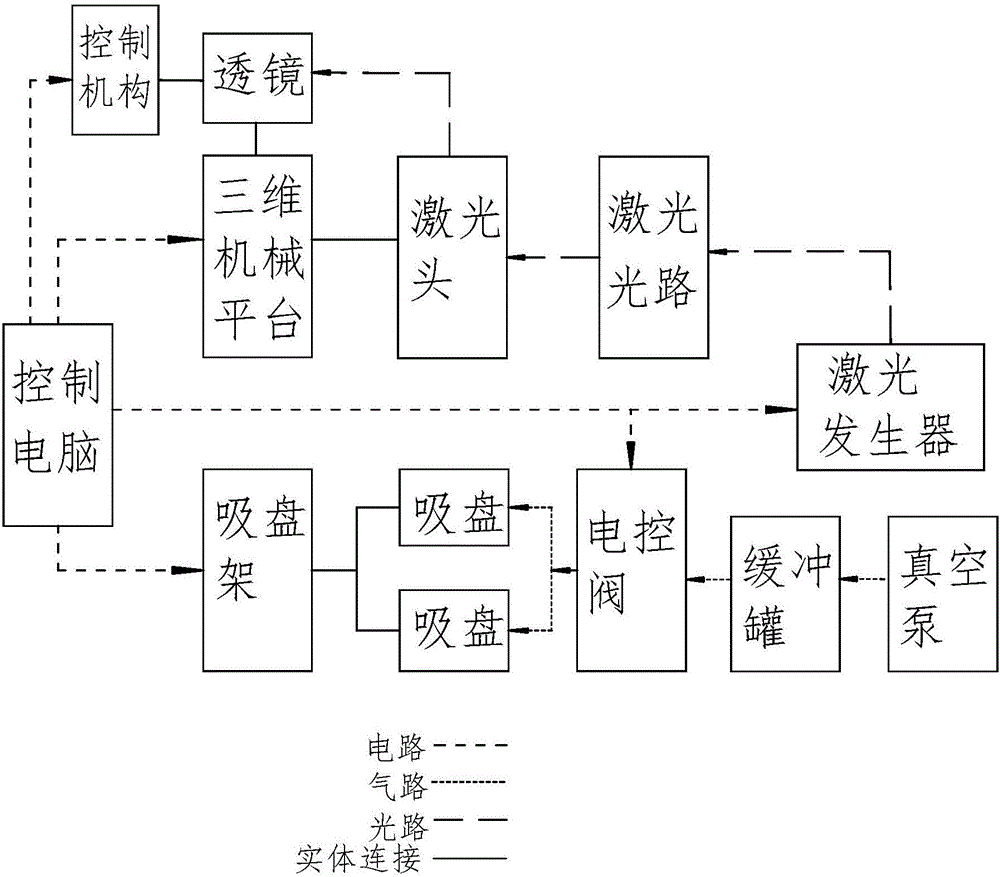

[0054] Illustrate vacuum glass production equipment and production method by the embodiment of the present invention:

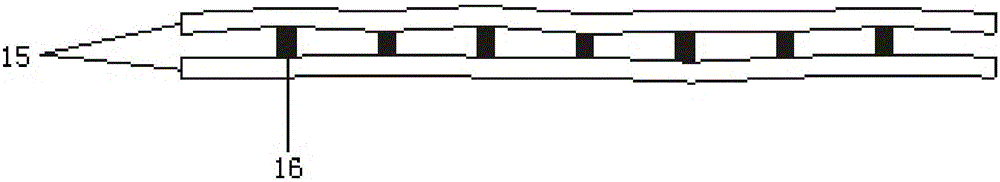

[0055] Taking flat glass as an example, such as Figure 4 As shown, the clamps in this embodiment are multiple rows of suction cup brackets 2, on which suction cup brackets 2 are arranged in rows, the inner opening of the suction cups is connected to the vacuum pump through the air circuit, and the control computer 13 is used to control the vacuum pump connected in series on the air circuit. The electric control valve is used to control the grabbing action of the suction cup. The two ends of each suction cup support 2 are controlled to lift by the support lifting cylinder 3, so the suction cup can be moved as a whole by the uniform absorption force of the top glass 9. The action of support lifting cylinder 3 is coordinated and controlled by control computer 13.

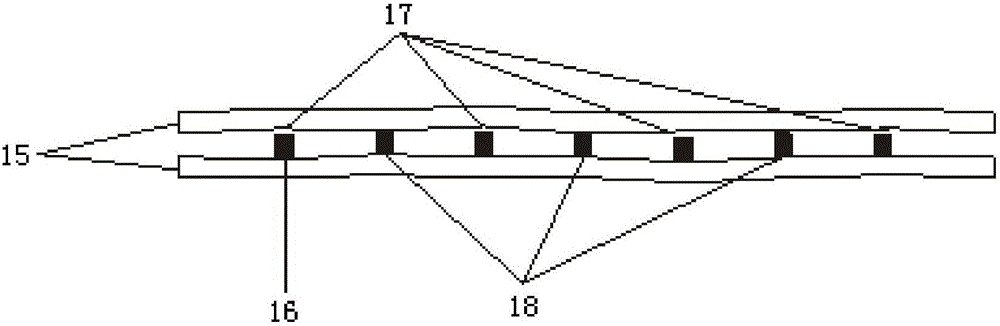

[0056] The laser head 14 is arranged on the three-dimensional mechanical platform, and the lase...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap