The method for treating waste lead-containing glass through melting method and preparing glass ceramics

A technology of glass-ceramics and melting method, which is applied in the field of processing and preparation of glass-ceramics, can solve the problems of restricting product application, affecting product performance, wasting resources, etc., to reduce lead content, improve product performance, save energy and reduce emissions The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

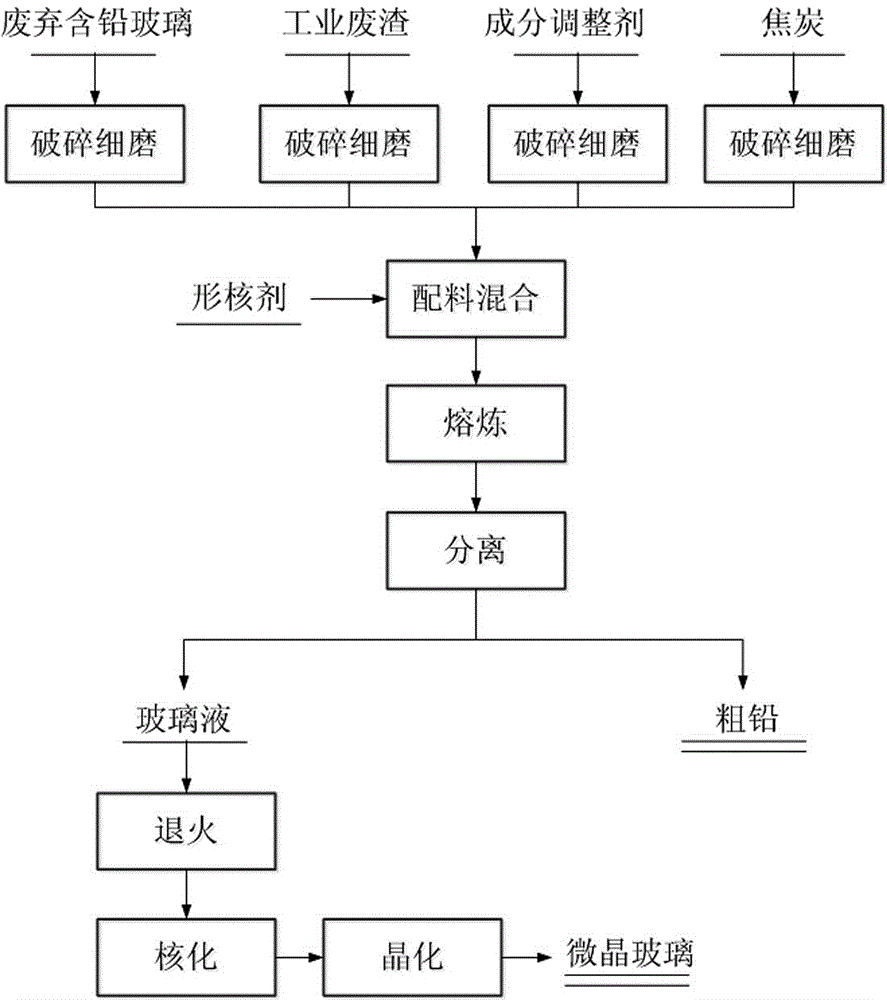

[0027] A method for processing waste lead-containing glass and preparing glass-ceramic by melting method, the process flow chart is as follows figure 1 shown, including the following steps:

[0028] (1) Crush fly ash, waste leaded glass, dolomite and coke to 0.2mm respectively;

[0029] (2) Taking the total mass of fly ash, waste lead-containing glass, composition regulator, and nucleating agent as 100%, according to fly ash 45%, lead-containing glass 35%, dolomite 14%, nucleation TiO 2 6%, and m (coke) / m (waste leaded glass) = 1.2% ingredients, mixed evenly, the chemical composition of the mixture according to the mass percentage is: SiO 2 38.1%, Al 2 o 3 15.8%, MgO 16.9%, R 2 O 5.1%, CaO 4.7%, Fe 2 o 3 3.4%, TiO 2 5.8%, PbO 8.6%, of which R 2 O for K 2 O and Na 2 O;

[0030] (3) Melt the mixed material at 1500°C for 2.5 hours, and separate the lower layer of crude lead to obtain the upper layer of molten glass;

[0031] (4) Put the upper layer of molten gl...

Embodiment 2

[0034] A method for processing waste lead-containing glass and preparing glass-ceramic by melting method, the process flow chart is as follows figure 1 shown, including the following steps:

[0035] (1) Crush fly ash, waste leaded glass, dolomite and coke to 0.074mm respectively;

[0036] (2) Taking the total mass of fly ash, waste lead-containing glass, composition modifier, and nucleating agent as 100%, according to fly ash 35%, lead-containing glass 40%, dolomite 12%, feldspar 5%, nucleating agent TiO 2 8%, and m (coke) / m (waste leaded glass) = 1.5% ingredients, mixed evenly, the chemical composition of the mixture according to the mass percentage is: SiO 2 39.3%, Al 2 o 3 15.5%, MgO15.4%, R 2O 5.5%, CaO 4.1%, Fe 2 o 3 3.0%, TiO 2 7.7%, PbO 9.4%, of which R 2 O for K 2 O and Na 2 O;

[0037] (3) Melt the mixed material at 1400°C for 3 hours, separate the lower layer of crude lead and obtain the upper layer of molten glass;

[0038] (4) Put the upper layer...

Embodiment 3

[0041] A method for processing waste lead-containing glass and preparing glass-ceramic by melting method, the process flow chart is as follows figure 1 shown, including the following steps:

[0042] (1) Crush fly ash, magnesite slag, waste lead-containing glass, dolomite and coke to 0.1mm respectively;

[0043] (2) Taking the total mass of fly ash, magnesite slag, waste lead-containing glass, composition regulator, and nucleating agent as 100%, according to fly ash 20%, magnesite slag 20%, and lead-containing glass 100% 35%, dolomite 5%, feldspar 10%, nucleating agent TiO 2 10%, and m (coke) / m (waste lead-containing glass) = 1.3% ingredients, mixed evenly, the chemical composition of the mixture according to the mass percentage is: SiO 2 36.1%, Al 2 o 3 15.2%, MgO 18.2%, R 2 O 4.1%, CaO 3.5%, Fe 2 o 3 4.0%, TiO 2 9.6%, PbO8.6%, of which R 2 O for K 2 O and Na 2 O;

[0044] (3) Melting the mixed material at 1550°C for 2 hours, separating the lower layer of cru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com