Concrete decorating plate and preparation method thereof

A technology for decorative panels and concrete, applied in the direction of chemical instruments and methods, lamination devices, hydraulically settable material layered products, etc., can solve problems such as harsh service environment, unsatisfactory durability, and impact on performance, so as to avoid easy cracking and peeling, reduce the breakage rate, and improve the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

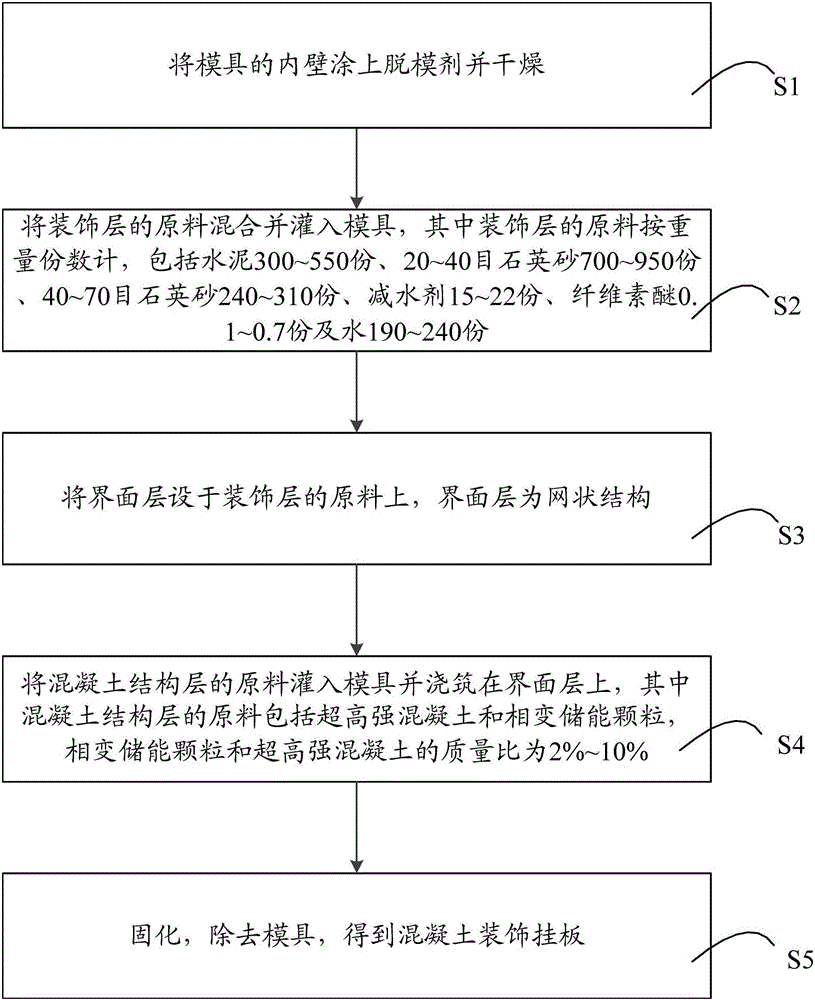

[0047] see figure 1 , the present invention also provides a preparation method for the above-mentioned concrete decorative board, comprising the following steps.

[0048] Step S1, coating the inner wall of the mold with a release agent and drying it. Step S1 is a pretreatment step of the mould.

[0049] This is beneficial to the demoulding of the subsequent concrete decorative panels. If step S2 is performed without waiting for the release agent to dry, the release agent may float up, thereby affecting the smooth progress of the release agent and the strength of the concrete decorative panel.

[0050] Preferably, the mold is a PVC plastic sheet.

[0051] Step S2, mixing and pouring the raw materials of the decorative layer into the mold, wherein the raw materials of the decorative layer are calculated in parts by weight, including 300-550 parts of cement, 700-950 parts of 20-40 mesh quartz sand, 240 parts of 40-70 mesh quartz sand ~310 parts, 15~22 parts of water reducing ...

Embodiment 1

[0065] The concrete decorative plate includes a concrete structure layer, an interface layer and a decorative layer arranged in sequence.

[0066] The raw materials of the concrete structure layer include ultra-high-strength concrete and phase-change microcapsules, and the mass ratio of the phase-change microcapsules and ultra-high-strength concrete is 3%. The interface layer is crack-resistant fiber mesh cloth. The raw materials of the decorative layer include 350 parts by weight of white cement, 750 parts of 20-40 mesh quartz sand, 250 parts of 40-70 mesh quartz sand, 300 parts of 325 mesh quartz sand, 16 parts of water reducer, fiber 0.4 parts of plain ether, 3 parts of phase change microcapsules, 0.9 parts of pigment and 190-240 parts of water.

[0067] The preparation method of this concrete decorative plate is as follows:

[0068] The PVC plastic sheet is used as the mold, and the release agent is evenly sprayed on the inner wall of the mold. Mix the raw materials of ...

Embodiment 2

[0070] The concrete decorative plate includes a concrete structure layer, an interface layer and a decorative layer arranged in sequence.

[0071] The raw materials of the concrete structure layer include ultra-high-strength concrete and phase-change microcapsules, and the mass ratio of phase-change microcapsules and ultra-high-strength concrete is 7%. The interface layer is steel mesh. The raw materials of the decorative layer include 500 parts by weight of white cement, 850 parts of 20-40 mesh quartz sand, 290 parts of 40-70 mesh quartz sand, 310 parts of 325-mesh quartz sand, 18 parts of water reducer, fiber 0.6 parts of plain ether, 5 parts of phase change microcapsules, 3 parts of pigment and 220 parts of water.

[0072] The preparation method of this concrete decorative plate is as follows:

[0073] The PVC plastic sheet is used as the mold, and the release agent is evenly sprayed on the inner wall of the mold. Mix the raw materials of the decorative layer in a mixer,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com