Castable for blast furnace slag spout

A blast furnace slag and castable technology, applied in the field of castables, can solve the problems of high production cost, large workload and low service life, and achieve the effects of improving service life, improving use effect and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Select corundum slag, the chemical composition of corundum slag is calculated as Al by weight percentage 2 o 3 ≥75%, MgO11~14%, CaO8~10%, Fe 2 o 3 ≤1%.

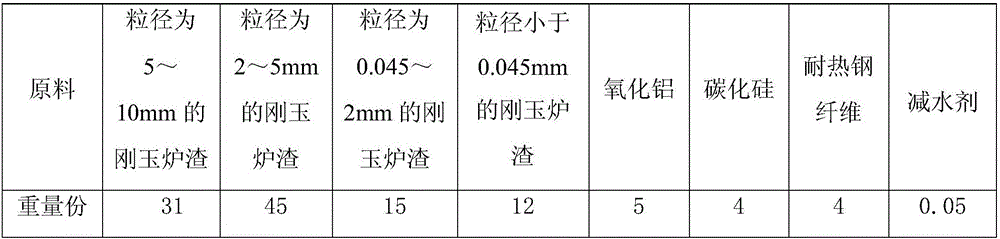

[0017] Prepare raw materials according to the mix ratio in Table 1

[0018]

[0019] Table I

[0020] Mix the above-mentioned various raw materials according to the mixing ratio in Table 1, then stir them into bags in the mixer, add water and stir them for more than 5 minutes when in use; pour the mixed materials into the mold poured by the slag ditch nozzle, and give them by vibrating rods. Vibration is applied to the castable to achieve the purpose of flow forming; the castable is demolded after natural hardening and drying, and is put into use after being naturally dried for 6 hours under the on-site temperature conditions.

[0021] The performance of the castable obtained by testing: the bulk density at 110°C is greater than 2.6g / cm 3 , 110°C drying compressive strength greater than 22Mpa, compressive stre...

Embodiment 2

[0023] Select corundum slag, the chemical composition of corundum slag is calculated as Al by weight percentage 2 o 3 ≥75%, MgO11~14%, CaO8~10%, Fe 2 o 3 ≤1%.

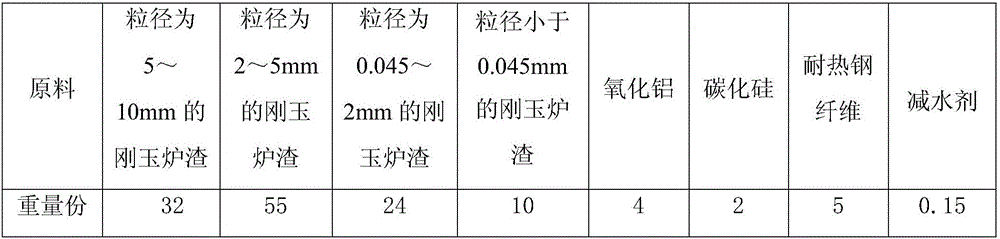

[0024] Prepare raw materials according to the mix ratio in Table 2

[0025]

[0026] Table II

[0027] Mix the above-mentioned various raw materials according to the mixing ratio in Table 2, then stir them into bags in the mixer, add water and stir for more than 5 minutes when in use; pour the mixed materials into the mold poured by the slag ditch nozzle, and give them to the mold through the vibrating rod Vibration is applied to the castable to achieve the purpose of flow forming; the castable is demolded after natural hardening and drying, and is put into use after being naturally dried for 6 hours under the on-site temperature conditions.

[0028] The performance of the castable obtained by testing: the bulk density at 110°C is greater than 2.8g / cm 3 , 110°C drying compressive strength greater than 27Mpa, c...

Embodiment 3

[0030] Select corundum slag, the chemical composition of corundum slag is calculated as Al by weight percentage 2 o 3 ≥75%, MgO11~14%, CaO8~10%, Fe 2 o 3 ≤1%.

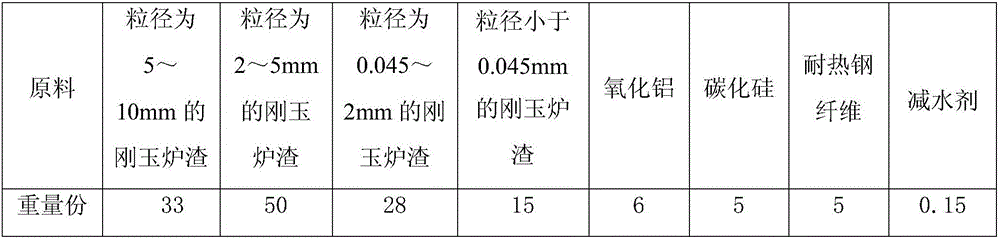

[0031] Prepare raw materials according to the mix ratio in Table 3

[0032]

[0033] Table three

[0034] Mix the above-mentioned various raw materials according to the mixing ratio in Table 3, then stir them into bags in the mixer, add water and stir for more than 5 minutes when in use; pour the mixed materials into the mold poured by the slag ditch nozzle, and give them to the mold through the vibrating rod Vibration is applied to the castable to achieve the purpose of flow forming; the castable is demolded after natural hardening and drying, and is put into use after being naturally dried for 6 hours under the on-site temperature conditions.

[0035] The performance of the castable obtained by testing: the bulk density at 110°C is greater than 2.7g / cm 3 The compressive strength is greater than 25Mpa when drie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com