Anti-mud polycarboxylate water reducing agent masterbatch with monoalkyl phosphate and di-alkyl phosphate branches

A technology of mono- and di-alkyl phosphate esters and polycarboxylic acids, which is applied in the field of cement additives, can solve problems such as limited adaptability, inability to uniformly solve the problems of water reducing rate and slump retention, and the increase of solid content or dosage, and achieve good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

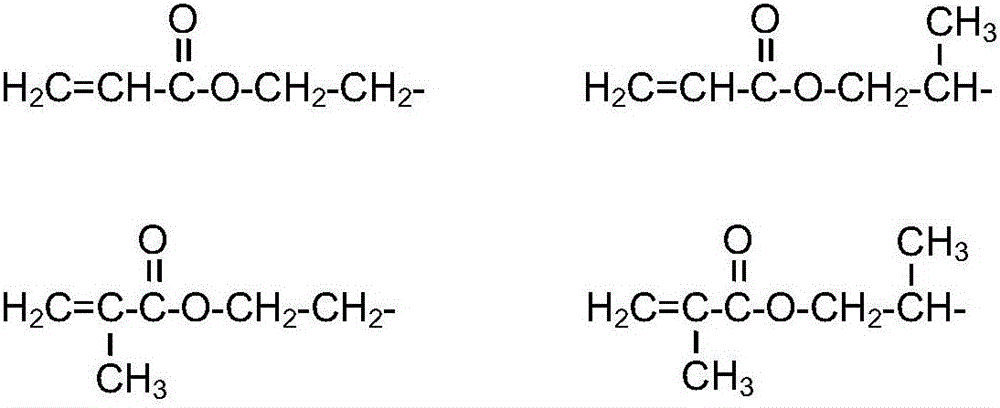

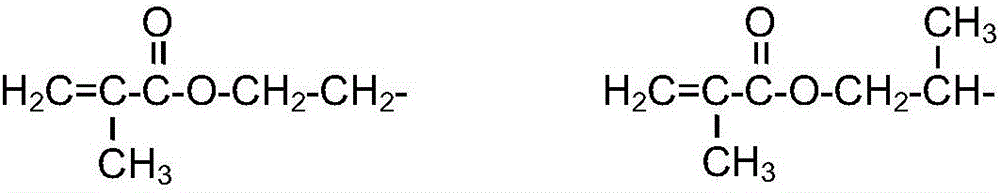

Method used

Image

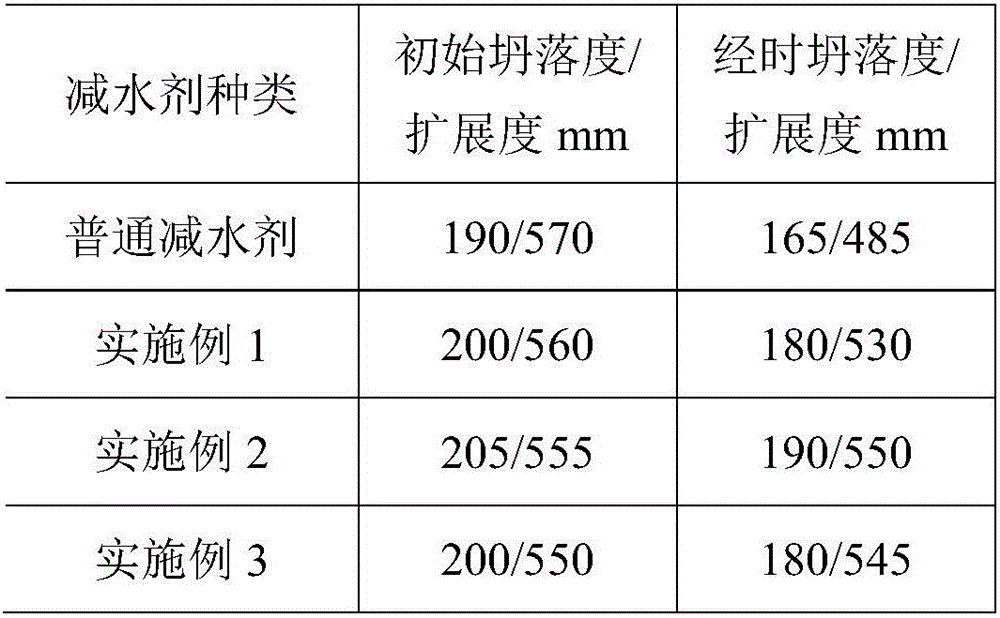

Examples

Embodiment 1

[0038] A mono- and di-alkyl phosphate branched anti-mud polycarboxylate superplasticizer masterbatch. The superplasticizer is polymerized from the following components. The total mass of raw materials is 1000. The components and process parameters are as follows:

[0039] Primer: methallyl polyoxyethylene ether with a molecular weight of 2400: 358, water: 220;

[0040] Hydrogen peroxide solution: 27.5% Industrial grade hydrogen peroxide: 3.5, water: 10;

[0041] After the hydrogen peroxide is added, sodium hypophosphite and one-third of the acrylic acid are added at one time;

[0042] Sodium hypophosphite: 3.0, acrylic acid (first cast): 11.0

[0043] After the above-mentioned phosphate-based chain transfer agent and one-third of the acrylic acid are injected at one time, add the initiator and the small monomer solution sequentially within 10 minutes;

[0044] Initiator: thioglycolic acid: 0.8, vitamin C: 0.75, water: 120;

[0045] Small monomer solution: acrylic acid (drop...

Embodiment 2

[0052] A mono- and di-alkyl phosphate branched anti-mud polycarboxylate superplasticizer masterbatch. The superplasticizer is polymerized from the following components. The total mass of raw materials is 1000. The components and process parameters are as follows:

[0053] Primer: 3000 molecular weight isobutylene alcohol polyoxyethylene ether: 355, water: 220;

[0054] Hydrogen peroxide solution: 27.5% Industrial grade hydrogen peroxide: 4.5, water: 10;

[0055] After the hydrogen peroxide is added, sodium hypophosphite and one-third of the acrylic acid are added at one time;

[0056] Disodium hydrogen phosphite: 1.5, acrylic acid (first cast): 12.0;

[0057] After the above-mentioned phosphate-based chain transfer agent and one-third of the acrylic acid are injected at one time, add the initiator and the small monomer solution sequentially within 10 minutes;

[0058]Initiator: thioglycolic acid: 1.0, vitamin C: 0.68, water: 120;

[0059] Small monomer solution: Acrylic aci...

Embodiment 3

[0066] A mono- and di-alkyl phosphate branched anti-mud polycarboxylate superplasticizer masterbatch. The superplasticizer is polymerized from the following components. The total mass of raw materials is 1000. The components and process parameters are as follows:

[0067] Primer: 3500 molecular weight isopentenol polyoxyethylene ether: 352, water: 220;

[0068] Hydrogen peroxide solution: 27.5% Industrial grade hydrogen peroxide: 4.5, water: 10;

[0069] After the hydrogen peroxide is added, sodium hypophosphite and one-third of the acrylic acid are added at one time;

[0070] Sodium hypophosphite: 3.5, sodium dihydrogen phosphate: 1.5, acrylic acid (first cast): 12.5;

[0071] After the above-mentioned phosphate-based chain transfer agent and one-third of the acrylic acid are injected at one time, add the initiator and the small monomer solution sequentially within 10 minutes;

[0072] Initiator: thioglycolic acid: 0.65, vitamin C: 0.57, water: 120;

[0073] Small monomer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com