Quaternary ammonium type hydrophilic amino-modified silicone oil emulsion and preparation method thereof

A technology of silicone oil emulsion and amino silicone oil, which is applied in the direction of improved hand feeling fibers, textiles and papermaking, fiber treatment, etc., can solve the problems affecting product soft feel, product stability, soft and slippery feel, etc., and achieve a significant deepening effect, The effect of low yellowing and small color change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

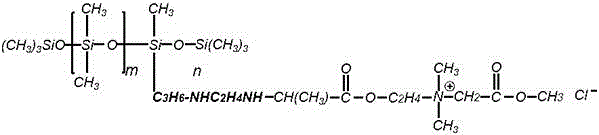

[0034] (1) Preparation of amino silicone oil: mix 660 grams of α, ω-hydroxy polydimethylsiloxane (silicone linear body) with 20 grams of N-(β-aminoethyl)-γ-aminopropylmethyl Dimethoxysilane, 0.2 g of 30% aqueous sodium hydroxide solution, and 5 g of hexamethyldisiloxane were reacted at 95° C. for 3 hours under a vacuum of 100 mbar, and neutralized with acetic acid to obtain amino silicone oil.

[0035] (2) Preparation of modified amino silicone oil: Add 685 grams of amino silicone oil and 15.6 grams of dimethylaminoethyl methacrylate into 210 grams of isopropanol solution and mix evenly, react at 30°C for 10 hours, Amino silicone oil modified with dimethylaminoethyl methacrylate was obtained.

[0036] (3) Quaternization reaction: Mix 1 g of the isopropanol solution of the modified amino silicone oil 910 with 10.8 g of methyl chloroacetate, and react at 80° C. for 8 hours to obtain a quaternized amino silicone oil.

[0037] (4) Inverse emulsification: Add 11.6 grams of acid to...

Embodiment 2

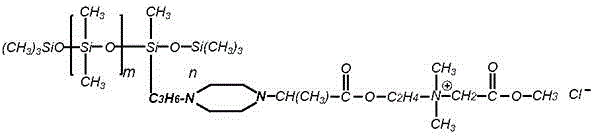

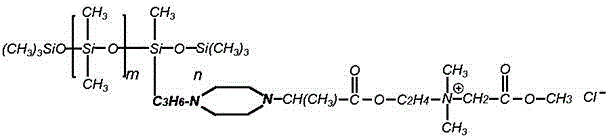

[0039] (1) Preparation of amino silicone oil: Mix 660 grams of α, ω-hydroxypolydimethylsiloxane (silicone linear body) with 25 grams of γ-piperazinylpropylmethyldimethoxysilane, 30% 0.2 g of aqueous sodium hydroxide solution and 5 g of hexamethyldisiloxane were reacted at 95° C. for 3 hours under a vacuum of 100 mbar, and neutralized with acetic acid to obtain amino silicone oil.

[0040] (2) Preparation of modified amino silicone oil: add 685 grams of amino silicone oil and 17 grams of dimethylaminoethyl methacrylate into 210 grams of isopropanol solution and mix evenly, react at 30°C for 10 hours, Amino silicone oil modified with dimethylaminoethyl methacrylate was obtained.

[0041] (3) Quaternization reaction: Mix 912 grams of isopropanol solution of the modified amino silicone oil with 23.5 grams of methyl chloroacetate, and react at 80° C. for 8 hours to obtain quaternized amino silicone oil.

[0042] (4) Inverse emulsification: Add 13 grams of acid to 935.5 grams of qu...

Embodiment 3

[0044] (1) Preparation of amino silicone oil: mix 660 grams of α, ω-hydroxypolydimethylsiloxane (silicone linear body) with 30 grams of N-(β-aminoethyl)-γ-aminopropylmethyl Dimethoxysilane, 0.2 g of 30% aqueous sodium hydroxide solution, and 5 g of hexamethyldisiloxane were reacted at 95° C. for 3 hours under a vacuum of 100 mbar, and neutralized with acetic acid to obtain amino silicone oil.

[0045] (2) Preparation of modified amino silicone oil: add 695 grams of amino silicone oil and 23 grams of dimethylaminoethyl methacrylate into 210 grams of isopropanol solution and mix evenly, react at 30°C for 10 hours, Amino silicone oil modified with dimethylaminoethyl methacrylate was obtained.

[0046] (3) Quaternization reaction: Mix 928 grams of isopropanol solution of the modified amino silicone oil with 16 grams of methyl chloroacetate, and react at 80° C. for 8 hours to obtain a quaternized amino silicone oil.

[0047] (4) Inverse emulsification: Add 17.5 grams of acid to 94...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com