Organosilicon darkening finishing agent and preparation method thereof

A finishing agent, silicone technology, applied in the field of printing and dyeing auxiliaries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1, a kind of organosilicon deepening finishing agent

[0026] The organosilicon darkening finishing agent includes the following components and their mass percentages: 15% butyl acrylate, 13% modifier, 0.1% catalyst, 3% composite emulsifier, 68.9% deionized water; the modified The agent is composed of piperazinylpropylmethyldimethoxysilane and vinyltriethoxysilane coupling agent in a mass ratio of 5:16; the catalyst is ammonium persulfate; the composite emulsifier is composed of isomerized ten Triol polyoxyethylene ether and dimethylene-1,2-bis(octadecyldimethylammonium bromide) consist of a mass ratio of 1:3; the EO of the isomerized tridecyl alcohol polyoxyethylene ether The number is 15.

[0027] The preparation method of the silicone darkening finishing agent, it comprises the following steps:

[0028] S1 Add compound emulsifier to deionized water, after fully dissolved, add butyl acrylate and modifier, emulsify in homogenizer, control the pressure of h...

Embodiment 2

[0030] Embodiment 2, a kind of organosilicon deepening finishing agent

[0031] The organosilicon darkening finishing agent includes the following components and their mass percentages: 18% butyl acrylate, 16.7% modifier, 0.3% catalyst, 5% composite emulsifier, 60% deionized water; the modified The agent is composed of cyclohexylaminosilane coupling agent and vinyltriethoxysilane coupling agent in a mass ratio of 10:8; the catalyst is azobisisobutyronitrile; Alcohol polyoxyethylene ether and dimethylene-1,2-bis(octadecyldimethylammonium bromide) are composed at a mass ratio of 1:1.5; the EO number of the isomerized tridecyl alcohol polyoxyethylene ether for 40.

[0032] The preparation method of the silicone darkening finishing agent, it comprises the following steps:

[0033] S1 Add compound emulsifier to deionized water, after fully dissolved, add butyl acrylate and modifier, emulsify in homogenizer, control the pressure of homogenizer at 100MPa, flow rate at 1000L / h, repe...

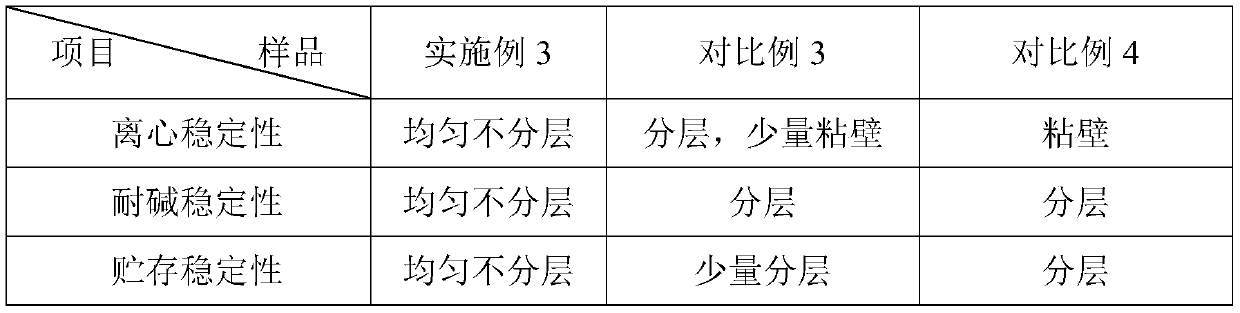

Embodiment 3

[0035] Embodiment 3, a kind of organosilicon deepening finishing agent

[0036] The organosilicon darkening finishing agent includes the following components and their mass percentages: 18% butyl acrylate, 15% modifier, 0.2% catalyst, 4% composite emulsifier, 62.8% deionized water; the modified The agent is composed of piperazinylpropylmethyldimethoxysilane and vinyltriethoxysilane coupling agent in a mass ratio of 7:12; the catalyst is ammonium persulfate; the composite emulsifier is composed of isomerized ten Triol polyoxyethylene ether and dimethylene-1,2-bis(octadecyldimethylammonium bromide) are composed at a mass ratio of 1:1.8; the EO of the isomerized tridecyl alcohol polyoxyethylene ether The number is 20.

[0037] The preparation method of the organosilicon darkening finishing agent, the steps are as follows:

[0038] S1 Add compound emulsifier to deionized water, after fully dissolved, add butyl acrylate and modifier, emulsify in homogenizer, control the pressure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com