A kind of pcl conductive plastic material and preparation method thereof

A technology of plasticizer and carbon nanotubes, which is applied in the field of PCL conductive plastic materials and its preparation, can solve the problems of inability to shape or deform, and achieve the effects of high retention rate of mechanical properties, high conductivity efficiency, and small addition amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

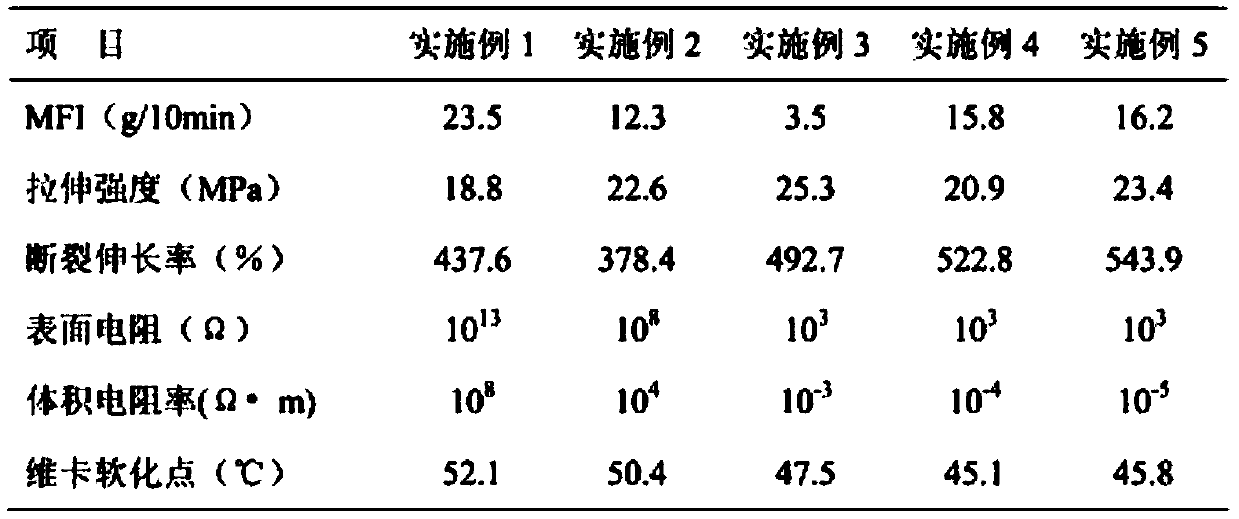

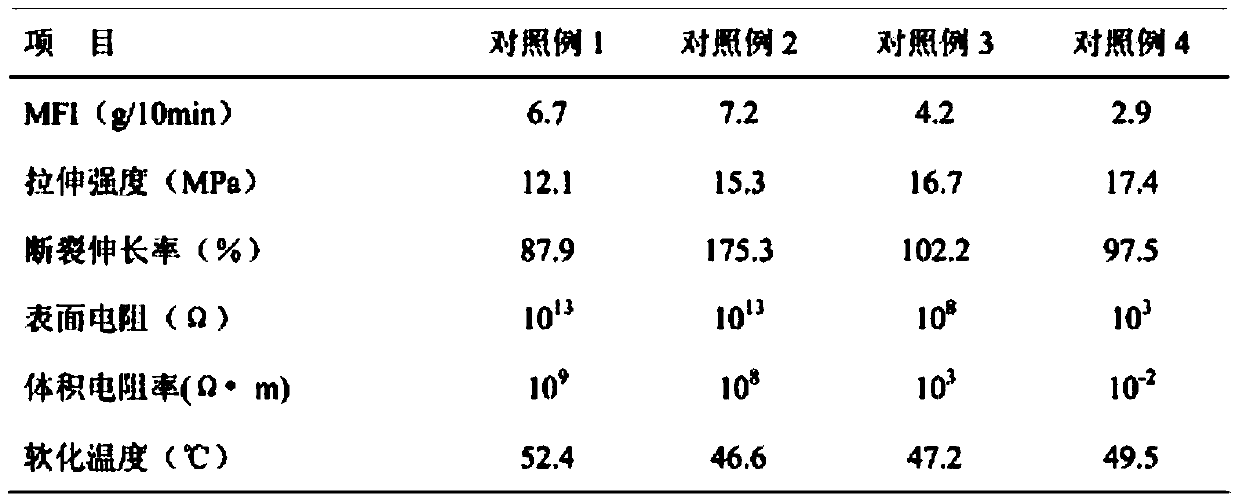

Examples

Embodiment 1

[0027] Accurately weigh 94.4 parts of PCL-1, 5 parts of N-butylbenzenesulfonamide, 0.5 parts of carbon nanotube CNTS-5, and 0.1 part of antioxidant 1010, pre-mix the above components evenly, and melt them with a single-screw extruder Mixing, extrusion and granulation to obtain PCL conductive plastic material; the temperature of the heating zone of the single-screw extruder from the feeding port to the machine head is set as follows: 130°C, 150°C, 150°C, 150°C, 150°C ℃, 150℃, rotating speed 300rpm.

Embodiment 2

[0029] Accurately weigh 79.8 parts of PCL-2 conductive compound, 15 parts of N-butylbenzenesulfonamide, 5 parts of carbon nanotube CNTS-5, 0.1 part of antioxidant 1076, 0.1 part of antioxidant 1010, and then pre- Mix evenly, use a twin-screw extruder to melt and knead, extrude and granulate to obtain a PCL conductive plastic material; the temperature in the heating zone of the twin-screw extruder from the feeding port to the machine head is set as follows: 100°C, 100°C °C, 120°C, 120°C, 120°C, 120°C, rotation speed 200rpm.

Embodiment 3

[0031] Accurately weigh 69.8 parts of PCL-3 conductive compound, 20 parts of N-butylbenzenesulfonamide, 10 parts of carbon nanotube CNTS-10, and 0.2 part of antioxidant 1076. Then the above-mentioned components were pre-mixed uniformly, melted and kneaded with an internal mixer; single-screw extruded and granulated to obtain PCL conductive plastic material; banburying temperature: 120°C, rotating speed 50rpm, banburying time 5 minutes; single-screw extrusion The temperature of the outlet heating zone from the feeding port to the machine head is set as follows: 130°C, 150°C, 150°C, 170°C, 170°C, 170°C, and the rotation speed is 400rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com