Lead-free aviation gasoline and preparation method thereof

A technology of unleaded aviation and aviation gasoline, which is applied in the petroleum industry, liquid carbon-containing fuel, fuel, etc., and can solve problems such as air pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0104] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0105] experiment method

[0106] The following test methods are used to measure various indicators of various raw materials and aviation gasoline.

[0107]

[0108]

[0109] The raw materials adopted in the following examples are as follows:

[0110] Component A1—Alkylation Unit Oil

[0111] The specifications for the alkylation unit oil as Component A are as follows:

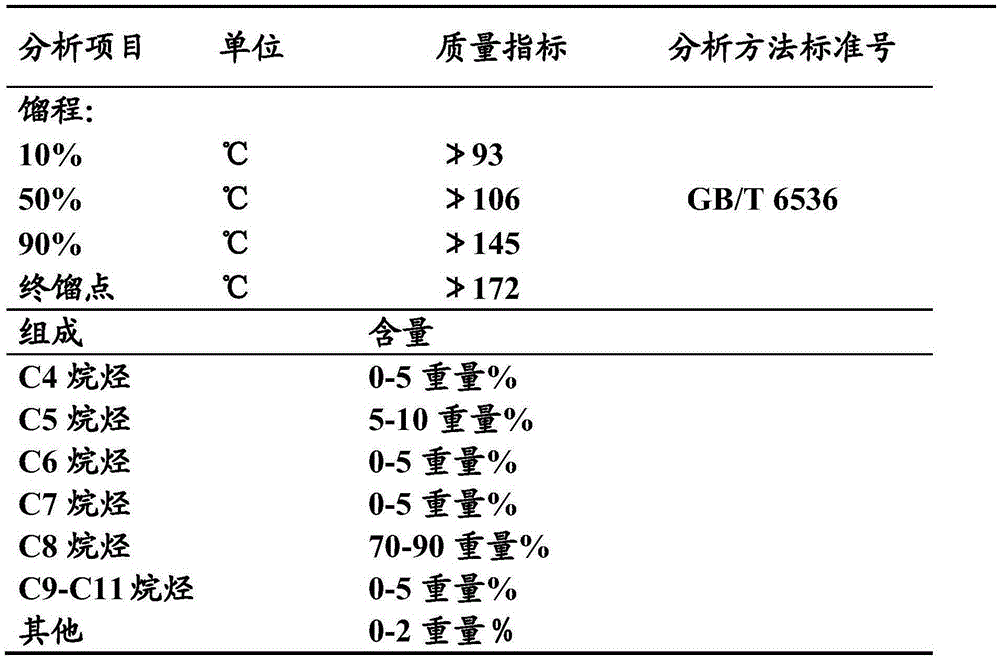

[0112]

[0113] Component A2—Alkylation Unit Oil

[0114] The specifications for the alkylation unit oil as Component A are as follows:

[0115]

[0116] Component B1—Pentane Component Oil Produced by Reforming Units

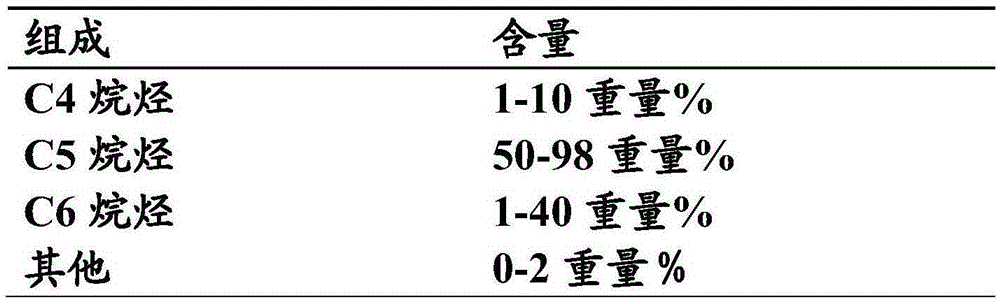

[0117] The indicator...

Embodiment 1

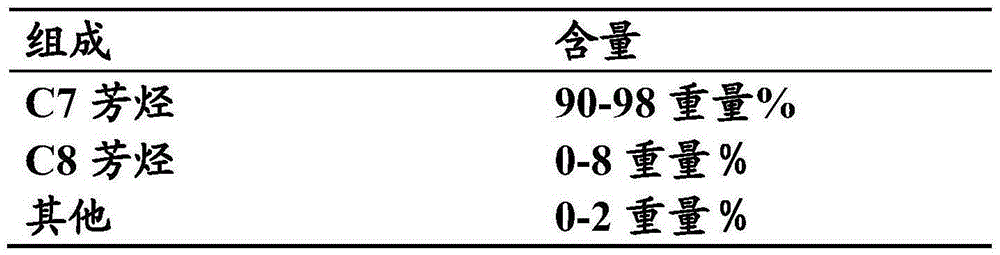

[0129] 75% alkylation unit oil (component A1), 5% reforming unit produced pentane component oil (component B1) and 15% C7 aromatic hydrocarbon component oil (component C1) and 5% of methyl tert-butyl ether (component E) was mixed uniformly to obtain unleaded aviation gasoline. Some physical and chemical property indicators of the unleaded aviation gasoline are shown in the following table:

[0130] Analysis Project Quality Index Octane number (motor method) 94.5 Research Octane Number 98 Initial boiling point, ℃ 34 10% distillation temperature, ℃ 69 50% distillation temperature, ℃ 102 90% distillation temperature, ℃ 111 End boiling point, °C 167 The sum of 10% and 50% distillation temperatures, °C 171 Percent loss, % 1.3 Residual percentage, % 1.2 Corrected recovery percentage, % 97.5 freezing point, ℃ <-70.0

Embodiment 2

[0132] Mix 85% by weight of the alkylation unit oil (component A2), 5% of the pentane component oil produced by the reforming unit (component B2) and 10% of the C7 aromatic hydrocarbon component oil (component C2) Evenly, unleaded aviation gasoline is obtained.

[0133] Analysis Project Quality Index Octane number (motor method) 91.2 Research Octane Number 96 Initial boiling point, ℃ 55 10% distillation temperature, ℃ 75 50% distillation temperature, ℃ 105 90% distillation temperature, ℃ 135 End boiling point, °C 165 The sum of 10% and 50% distillation temperatures, °C 180 Percent loss, % 1.3 Residual percentage, % 1.2 Corrected recovery percentage, % 97.5 freezing point, ℃ -60 Sulfur content, mg / kg 5 Net calorific value, MJ / kg 43.5 Volume change, ML 0 Conductivity, ps / m 393 Copper sheet corrosion (100℃, 2h), grade 1a Lead content, g / L <0.0013

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com