Method for preparing super-hydrophobic copper surface of plant leaf structure

A plant leaf, super-hydrophobic technology, applied in electroforming, electrolysis process, etc., can solve the problem of loss of multi-level complexity of the original template structure, no longer exist, etc., to achieve the effect of super-hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Step 1: Put the lotus leaf in an oven at 100°C and dry it for 48 hours, then place it in an argon atmosphere furnace and heat it up to 800°C at a rate of 1°C / min to prepare a carbon template with the microstructure of the lotus leaf ;

[0021] Step 2, use the carbon template as the cathode electrode of the electrolytic cell, and perform electroplating in a copper sulfate solution, the concentration of the copper sulfate solution is 0.5mol / L, and the current density is 0.04A / cm 2 , the electroplating time is controlled to be 1min, and the copper surface with lotus leaf microstructure is obtained;

[0022] Step 3, immerse the copper-plated carbon template in a mixed solution of isopropanol and fluorosilane with a volume fraction of 20% fluorosilane, take it out after soaking for 6 days, and dry it to obtain a superhydrophobic copper surface with a lotus leaf microstructure ;

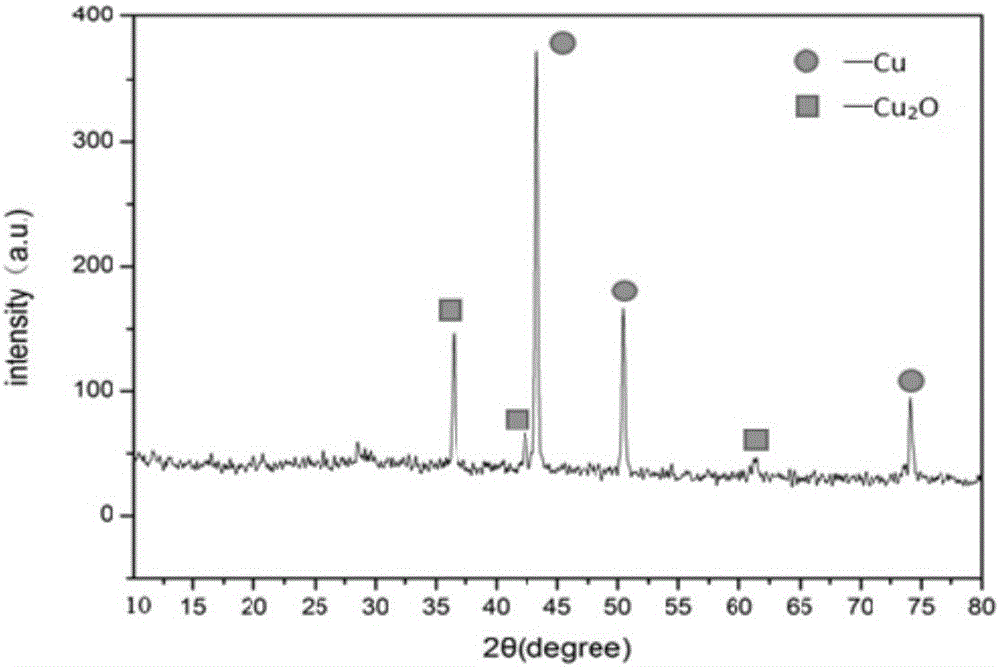

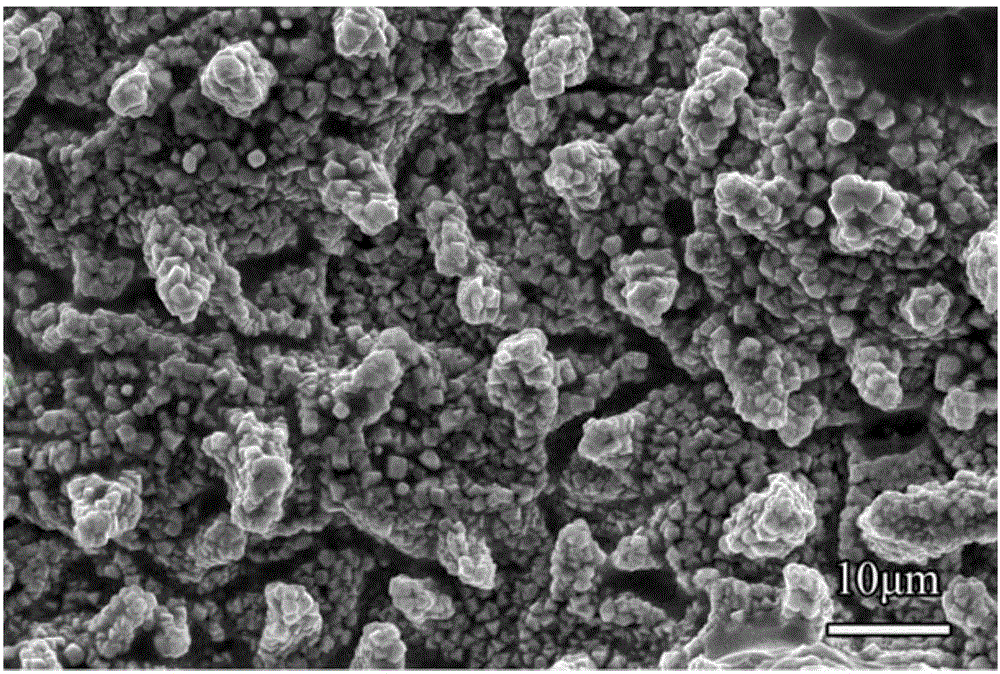

[0023] figure 1 To obtain the X-ray diffraction pattern of the copper surface, it can be seen...

Embodiment 2

[0025] Step 1: Put the lotus leaf in an oven at 80°C and dry it for 24 hours, then place it in an argon atmosphere furnace and heat it up to 600°C at a rate of 5°C / min to prepare a carbon template with the microstructure of the lotus leaf ;

[0026] Step 2, use the carbon template as the cathode electrode of the electrolytic cell, and perform electroplating in a copper sulfate solution, the concentration of the copper sulfate solution is 0.3mol / L, and the current density is 0.04A / cm 2 , control the electroplating time to be 5min, obtain the copper surface with lotus leaf microstructure;

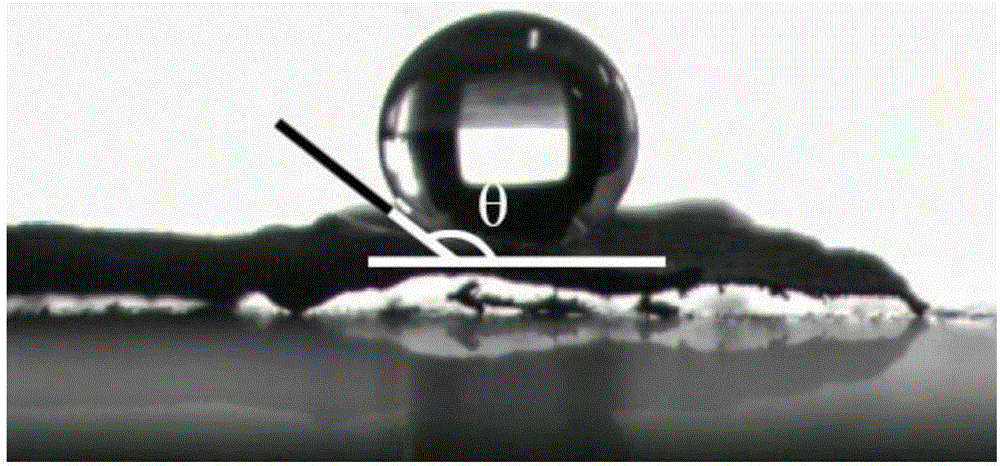

[0027] Step 3, immerse the copper-plated carbon template in a mixed solution of isopropanol and fluorosilane with a volume fraction of 20% of fluorosilane, take it out after soaking for 5 days, and dry it to obtain a superhydrophobic copper surface with a lotus leaf microstructure . The contact angle of the superhydrophobic copper surface with water, θ 接触角 =151°, reaching superhydrophobici...

Embodiment 3

[0029] Step 1, put the zong leaves in an oven at 120°C, bake and dry for 24 hours, then place them in a nitrogen atmosphere furnace and heat them to 600°C at a heating rate of 2°C / min to prepare a carbon template with the microscopic structure of zong leaves;

[0030] Step 2, use the carbon template as the cathode electrode of the electrolytic cell for electroplating in copper sulfate solution, the concentration of copper sulfate solution is 0.1mol / L, and the current density is 0.03A / cm 2 , control electroplating time 5min, obtain the copper surface with the microstructure of Zongye;

[0031] Step 3, immerse the copper-plated carbon template on the surface in a mixed solution of isopropanol and fluorosilane with a volume fraction of 15% of fluorosilane, take it out after soaking for 10 days, and then dry it to obtain superhydrophobic copper with the microscopic structure of zongzi leaves surface. Figure 4 is the contact angle between the prepared superhydrophobic copper surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com